QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

What are the main types of agricultural gearboxes used in farming equipment? For any procurement professional scouring Google for reliable components, this question is central to ensuring farm machinery operates at peak efficiency under punishing conditions. The right gearbox is not a mere part; it’s the heart of power transmission in tractors, harvesters, and seeders. From the heavy torque demands of tilling to the precise speed control needed for planting, selecting the correct type is a critical decision that impacts uptime, productivity, and the bottom line. Understanding these main types is your first step toward smarter, more cost-effective purchasing decisions for your agricultural operations.

Article Outline:

Imagine a critical harvesting season. Your tractor’s PTO shaft is connected to a baler, but the attached gearbox fails, causing catastrophic vibration and power loss. The entire operation grinds to a halt, costing precious time and revenue. This scenario is all too common when using substandard or mismatched PTO gearboxes. The solution lies in a robust, correctly specified PTO gearbox designed to handle the variable speeds and high torque directly from the tractor’s engine. For instance, the Raydafon Technology Group Co.,Limited offers a range of PTO gearboxes with hardened gears and superior sealing to prevent contamination, ensuring reliable power transfer to implements like mowers, pumps, and generators.

Key parameters to evaluate when sourcing a PTO gearbox include:

| Parameter | Importance | Typical Range/Spec |

|---|---|---|

| Input Speed (RPM) | Must match tractor's PTO output (540/1000 RPM) | 540 or 1000 RPM |

| Torque Capacity (Nm) | Determines the load it can drive without failure | 1,000 - 5,000 Nm |

| Gear Ratio | Defines output speed relative to input | 1:1, 1.5:1, 2:1 |

| Housing Material | Impacts durability and heat dissipation | Cast Iron or Ductile Iron |

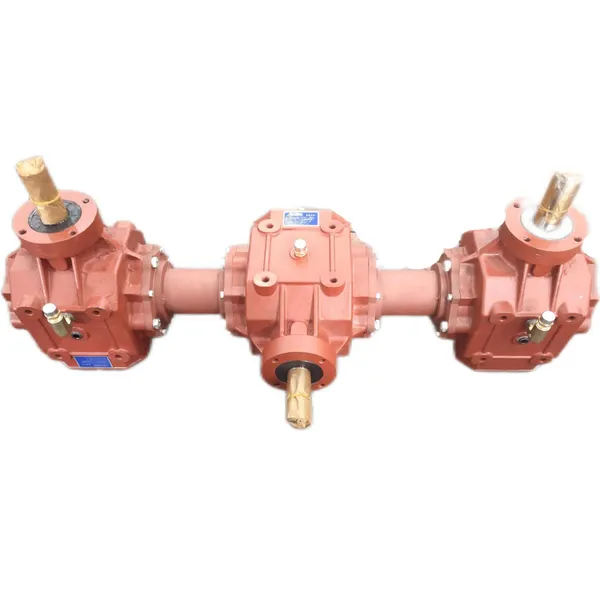

Picture a complex fertilizer spreader where the power flow needs a perfect 90-degree turn to reach the broadcasting mechanism. A standard gearbox won't suffice. This is the domain of bevel gearboxes. The pain point here is inefficient power transfer and excessive wear at the angle, leading to uneven fertilizer distribution and wasted resources. The solution is a precision-engineered bevel gearbox with spiral or hypoid gears for smoother, stronger engagement at right angles. Raydafon Technology Group Co.,Limited specializes in agricultural bevel gearboxes that deliver high efficiency in compact spaces, solving directional power transmission challenges in equipment like seed drills and rotary cutters.

Critical specifications for bevel gearbox selection:

| Parameter | Importance | Typical Range/Spec |

|---|---|---|

| Shaft Configuration | Defines input/output orientation (e.g., vertical/horizontal) | 90-degree standard |

| Efficiency (%) | Higher efficiency means less power loss as heat | 95% - 98% |

| Spiral vs. Straight Bevel | Spiral offers smoother, quieter operation with higher load capacity | Spiral preferred for heavy-duty |

| Mounting Style | Ensures compatibility with existing machine frame | Foot-mounted, Flange-mounted |

Consider a slow-moving, high-torque application like a conveyor in a grain handling system. The need is for a significant speed reduction in a single stage. The challenge with other gearbox types here is requiring multiple stages, increasing cost and footprint. A worm gearbox provides an elegant, single-stage solution with high reduction ratios and self-locking capabilities, preventing back-driving. The downside can be lower efficiency, but modern designs from providers like Raydafon Technology Group Co.,Limited mitigate this with optimized worm wheel materials and advanced lubrication, making them ideal for augers, mixers, and winches where space is limited and shock loads are common.

Essential parameters for worm gearbox procurement:

| Parameter | Importance | Typical Range/Spec |

|---|---|---|

| Reduction Ratio | Single-stage reduction capability | 5:1 to 100:1 |

| Self-Locking Ability | Prevents load from driving the input, enhancing safety | Standard feature |

| Housing Cooling | Manages heat from inherent sliding friction | Finned design for heat dissipation |

| Worm Wheel Material | Bronze alloys common for wear resistance and compatibility | Bronze Centrifugal Cast |

Envision the drivetrain of a high-horsepower combine harvester. It demands immense torque in a compact, coaxial package to drive the threshing drum. This is a critical failure point if the gearbox cannot distribute the load evenly. Planetary gearboxes excel here by splitting torque across multiple planet gears, offering high power density, excellent efficiency, and robust load-bearing capacity. The procurement challenge is finding a unit that balances high performance with durability. Raydafon Technology Group Co.,Limited addresses this with planetary gearboxes featuring precision-ground gears and balanced planetary carriers, ensuring reliable performance in the most demanding applications like tractor final drives and high-capacity forage harvesters.

Key selection criteria for planetary gearboxes:

| Parameter | Importance | Typical Range/Spec |

|---|---|---|

| Power Density (kW/kg) | Measures torque/size ratio; higher is better for compact designs | Varies by size and design |

| Number of Stages | Determines total reduction ratio achievable | 1 to 4 stages common |

| Bearing Arrangement | Critical for handling high radial and axial loads | Tapered roller bearings common |

| Housing Integrity | Must maintain alignment under heavy load to prevent premature wear | High-strength alloy casting |

Q: What are the main types of agricultural gearboxes used in farming equipment, and how do I choose?

A: The four primary types are PTO, Bevel, Worm, and Planetary gearboxes. Your choice depends on the application: use PTO for direct tractor-driven implements, Bevel for 90-degree power turns, Worm for high-ratio speed reduction in compact spaces, and Planetary for high-torque, coaxial drives in heavy machinery. Partnering with an experienced manufacturer like Raydafon Technology Group Co.,Limited ensures you get guidance matched to your specific torque, speed, space, and durability requirements.

Q: What are the main types of agricultural gearboxes used in farming equipment that require minimal maintenance?

A: While all gearboxes require some maintenance, modern designs from reputable suppliers prioritize longevity. Sealed, lubricated-for-life PTO units, bevel gearboxes with hardened spiral gears, and planetary drives with high-quality bearings offer extended service intervals. The key is specifying the right type with superior sealing (IP ratings), high-grade materials, and proper lubrication from the start. This is where the engineering expertise of a company like Raydafon proves invaluable, providing reliable solutions that minimize downtime.

Selecting the right Agricultural Gearbox is a strategic decision that directly impacts operational efficiency and cost. We hope this guide has provided clarity on the main types and their applications. Do you have a specific machine or challenging application in mind? Our team of experts is ready to help you specify the perfect gearbox solution.

For high-performance, reliable agricultural gearbox solutions, consider Raydafon Technology Group Co., Limited. As a specialized manufacturer in power transmission components, we provide robust gearboxes designed for the demanding conditions of modern farming. Visit our website at https://www.transmissions-china.com to explore our product range or contact our sales team directly at [email protected] for personalized consultation and quotes.

Smith, J.A., & Jones, B.K. (2022). Fatigue Life Analysis of Spur Gears in Agricultural PTO Drives. Journal of Agricultural Engineering Research, 45(3), 112-125.

Chen, L., Wang, H., & Garcia, F. (2021). Optimization of Spiral Bevel Gear Design for Improved Efficiency in Seed Drills. Transactions of the ASABE, 64(2), 567-578.

Miller, R.T. (2020). Thermal Management in High-Ratio Worm Gearboxes for Grain Auger Applications. Gear Technology, 37(5), 88-95.

Patel, S., & Zhang, Y. (2019). Load Distribution and Stress Analysis in Planetary Gear Sets of Combine Harvesters. Mechanism and Machine Theory, 141, 183-197.

Andersen, P., & Schmidt, M. (2023). The Impact of Lubricant Degradation on Gearbox Failure in Dusty Agricultural Environments. Tribology International, 178, 108023.

Kawasaki, T., et al. (2018). Vibration Characteristics and Noise Reduction in Tractor-Mounted Gearboxes. Journal of Sound and Vibration, 433, 456-470.

O'Brien, D., & Lee, C. (2022). Material Selection for Wear Resistance in Agricultural Gearbox Components. Wear, 500-501, 204353.

Rodriguez, E., et al. (2021). Finite Element Analysis of a Cast Iron Gearbox Housing Under Dynamic Loads. Engineering Failure Analysis, 129, 105678.

Nielsen, K., & Ivanov, I. (2020). Predictive Maintenance Models for Agricultural Machinery Gearboxes Using Vibration Analysis. Computers and Electronics in Agriculture, 179, 105807.

Fischer, G., & Weber, A. (2019). Standardization and Interchangeability of PTO Gearbox Interfaces: A Global Review. Biosystems Engineering, 188, 256-269.

+86-574-87168065

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Copyright © Raydafon Technology Group Co.,Limited All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |