QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Raydafon is a Chinese manufacturer specializing in Forklift Hydraulic Cylinder, and has long provided high-quality hydraulic cylinder products to whole-machine factories and forklift maintenance channels. As a mature local manufacturer, we rely on standardized quality inspection processes and stable production systems to deliver quickly while ensuring quality and quantity, and have reliable global supply capabilities. The product pricing is reasonable and has won a good reputation in both domestic and foreign markets.

Raydafon's Forklift Hydraulic Cylinder is suitable for various types of forklifts, including electric forklifts, internal combustion forklifts, stackers and storage equipment. For different tonnages and operating intensities, we can provide customized solutions with different cylinder diameters, strokes and connection end styles. Whether it is used for gantry lifting, body tilting, or side shifting mechanisms, it can maintain smooth movement and fast response, helping to improve equipment operation efficiency. The hydraulic cylinder has a sturdy structure and stable sealing performance. The key components are made of high-strength alloy steel, and the surface is electroplated or hard chrome treated. It has good corrosion resistance and wear resistance, and can cope with frequent operations and harsh use environments.

All our products have gone through multiple processing and testing procedures, including key dimensions controlled by CNC machining centers, professional sealing assembly processes, and multiple pressure tests before the assembly leaves the factory, ensuring that each Forklift Hydraulic Cylinder can be used directly on the vehicle after leaving the factory. Raydafon's hydraulic cylinders are now exported to Europe, Southeast Asia, South America and other regions, widely serving the original equipment and aftermarket replacement markets. We also support OEM and ODM project development, and can be customized according to the drawings or technical requirements provided by customers to meet the differentiated needs of special forklifts and high-end customers.

Whether you are a forklift manufacturer, a hydraulic system integrator, or a maintenance unit responsible for terminal equipment maintenance, Raydafon can provide you with a stable supply of cost-effective Forklift Hydraulic Cylinders, and maintain high efficiency and fast response in all aspects of selection, drawing, proofing, and delivery. Choosing Raydafon means choosing a worry-free, professional, and long-term guaranteed partner.

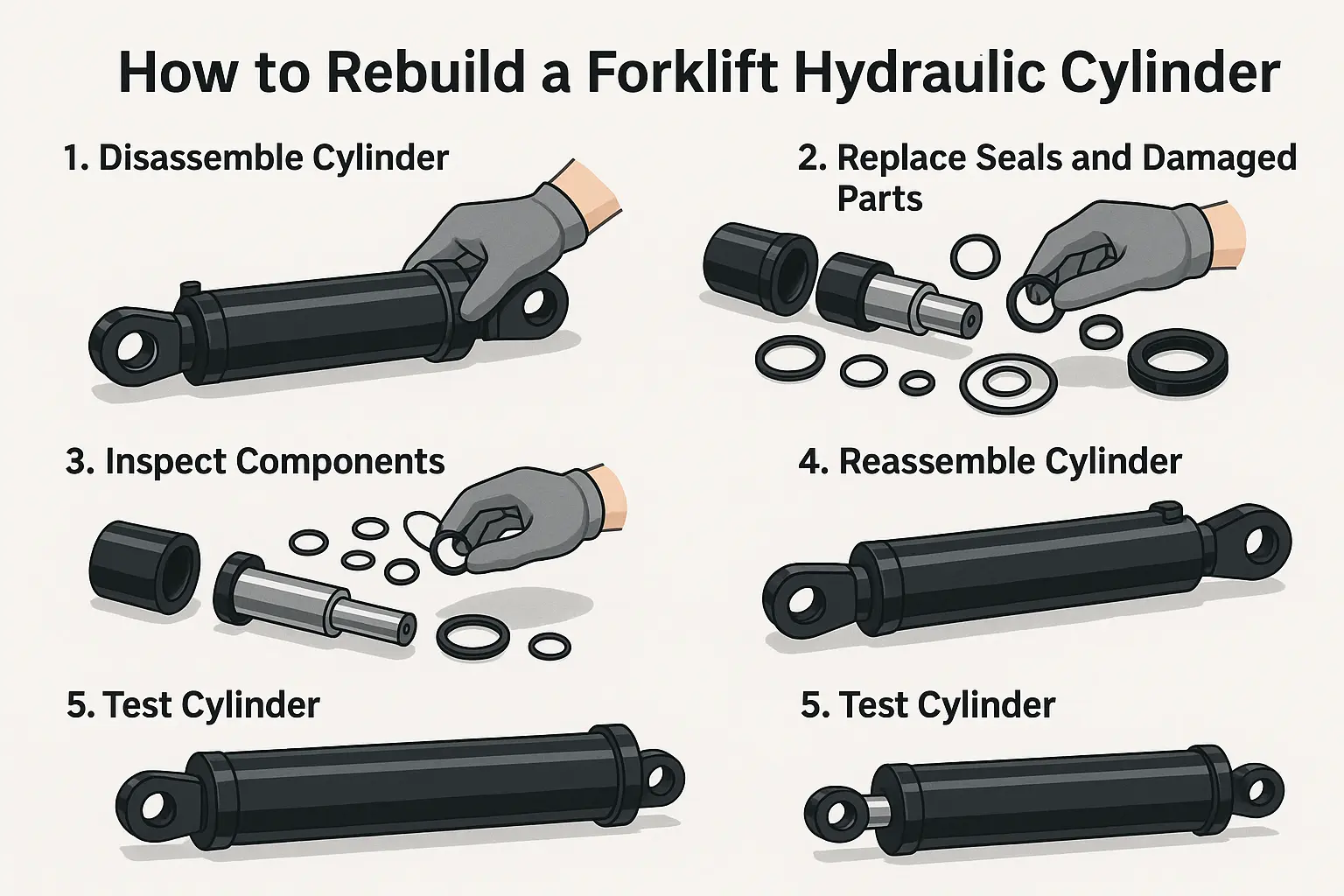

Rebuilding a forklift hydraulic cylinder is not as easy as simply unscrewing and replacing the rubber ring. The whole process involves multiple steps, and each step must be handled carefully, otherwise it will not last for a few days after it is installed again.

The first step is to make sure that the system has been depressurized and the hydraulic cylinder has been removed from the vehicle. Loosen the end cover bolts with a wrench and carefully pull out the piston rod assembly to avoid scratching the inner wall of the cylinder. If there is too much oil inside, it is recommended to clean it before operation.

The second step is to check the removed piston, rod, seal ring, etc. one by one to see if there is any deformation, wear, edge loss or rust. Don't underestimate a wear mark, which may be the culprit of the leak.

The third step is to replace all aging or damaged seals. When selecting parts, make sure that the specifications are consistent. Some cylinders use combined seals, so don't install them in the wrong direction.

The fourth step is to reinstall the parts as they were. Be gentle when installing the piston rod, and pay attention to keeping the center axis aligned, otherwise even the best cylinder will leak oil after a few days.

The last step is to hang the installed hydraulic cylinder on the pressure test equipment to check for internal leakage or jamming. After ensuring that there is no problem, install it back to the forklift for use.

If you find that the piston rod is bent or the cylinder is seriously strained during the disassembly process, don't force it to be repaired. It is easier to replace it with a new one. Raydafon provides a full range of Forklift Hydraulic Cylinders and accessories, and can also provide repair kits according to customer needs, which is suitable for forklift repairers and equipment engineers to quickly restore on-site equipment operation. It is better to choose the right one than to repair it well.

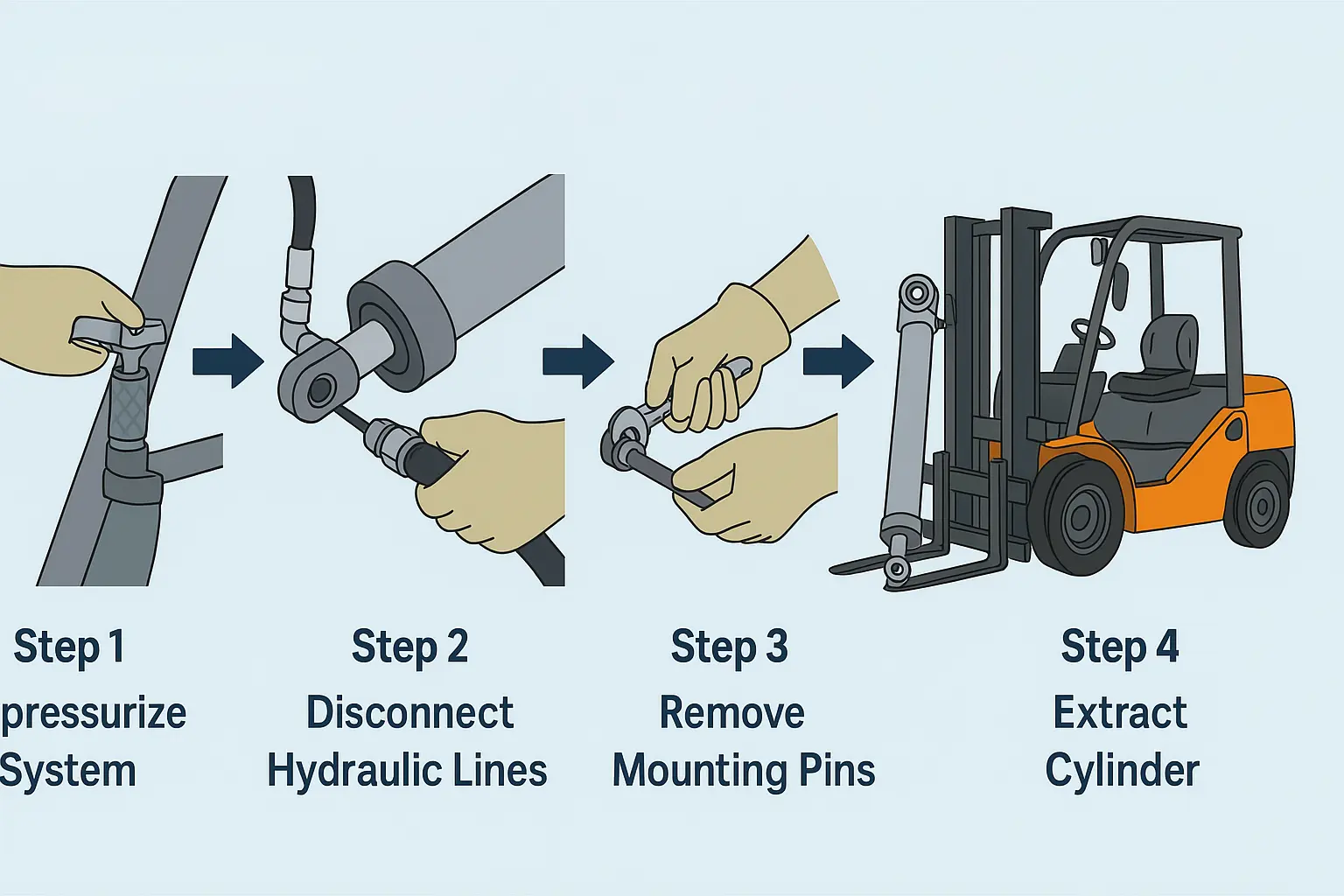

To correctly remove the hydraulic cylinder on the forklift, the sequence of steps and the details of the operation are the key. Improper operation will not only make it impossible to remove it, but may also damage the components or cause safety risks.

The first step is to release the pressure of the hydraulic system. Turn off the forklift to allow the hydraulic system to release pressure naturally, and wait for a few minutes to ensure that all the pressure has been discharged.

The second step is to disconnect the oil pipe. Wrap the joint with cloth to prevent oil leakage, remove the high-pressure hose connected to the hydraulic cylinder, and mark it for easy reinstallation.

The third step is to loosen the fixing pin or bolt. The hydraulic cylinder is usually connected to the gantry or frame through the pin shaft at the front and back. Find the pin position (if there is a retaining ring, remove the retaining ring first and then move the pin shaft), knock out the fixing pin or remove the bolt.

The fourth step is to carefully remove the hydraulic cylinder. The entire cylinder body is heavy. It is recommended that two people operate or use a sling. Be careful not to hit the surrounding structure and keep the cylinder mouth facing up to prevent the internal residual oil from overflowing.

After the hydraulic cylinder is removed, the oil port should be sealed immediately to prevent dust and rust. If it is a repair or replacement, Raydafon provides hydraulic cylinder products and seal kits that match various forklift models to help users quickly restore equipment operation.

Raydafon is a manufacturer focusing on hydraulic and transmission system solutions. We do not pursue fancy publicity, but make products steadily and win the trust of customers with reliable quality. Over the years, we have focused on the development and production of various types of hydraulic cylinders, with rich models and flexible adaptation, and widely serve the fields of engineering machinery and special vehicles.

Our hydraulic cylinder products cover multiple application directions, including mobile crane hydraulic cylinders, garbage truck hydraulic cylinders, aerial work vehicle hydraulic cylinders, etc. The products use high-strength materials and precision processing technology to ensure stable operation under high-pressure and high-frequency working scenarios, and extend the service life of the equipment.

In addition to hydraulic cylinders, Raydafon also provides a complete power transmission product line, including PTO shaft and agricultural gearbox. Whether it is a complete machine manufacturer, repairer or parts dealer, we can provide customers with one-stop matching services, eliminating tedious docking and improving overall efficiency.