QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

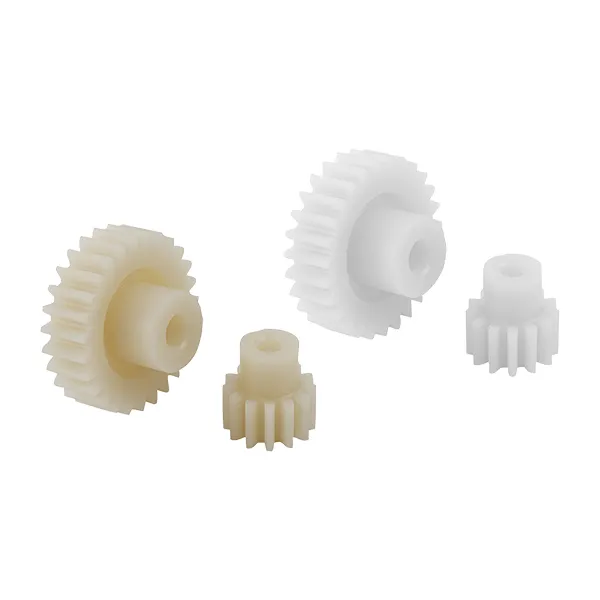

What are the standard sizes and specifications for spur gears? If you're searching for this, you're likely deep in the sourcing process, trying to match a precise mechanical need with a reliable component. The world of spur gears is governed by a system of standardized sizes and specifications, primarily based on diametral pitch (DP) or module (M), pressure angles (commonly 20° or 14.5°), and a range of face widths. Understanding these standards is the key to ensuring compatibility, performance, and longevity in your assembly. For sourcing professionals, finding a supplier who not only provides these standard parts but also offers expert guidance and customization is crucial. This is where partnering with an experienced manufacturer like Raydafon Technology Group Co.,Limited makes all the difference, turning a complex specification sheet into a simple, reliable procurement decision.

Article Outline:

You've finalized the CAD model for your new device. The prototype assembly is scheduled for next week. You order "standard" spur gears from a general hardware supplier, only to find they don't mesh correctly. The pitch is slightly off, causing binding and noise, derailing your entire timeline. This common scenario highlights why knowing precise specifications like module (for metric) or diametral pitch (for imperial) is non-negotiable. A slight deviation from the standard can render a component useless. The solution is to work with specialists who treat standards as a baseline, not a limitation. At Raydafon Technology Group Co.,Limited, we provide gears built to exacting AGMA, ISO, or JIS standards, ensuring perfect fit and function from the first prototype. Our engineers can cross-reference your requirements to guarantee the gear you receive is the one your design demands.

Here is a quick reference table for common standard spur gear specifications:

| Specification | Typical Standard Range | Notes for Sourcing |

|---|---|---|

| Module (M) - Metric | 0.5, 1, 1.5, 2, 3, 4, 5, 6, 8 | Module = Pitch Diameter / Number of Teeth. Higher module = larger, stronger teeth. |

| Diametral Pitch (DP) - Imperial | 20, 16, 12, 10, 8, 6, 4, 3 | DP = Number of Teeth / Pitch Diameter (inches). Higher DP = finer, smaller teeth. |

| Pressure Angle | 20° (most common), 14.5° (older standards) | 20° offers better strength and load capacity. Must match between mating gears. |

| Face Width | Varies with application; often 3-5 times the module | Wider face increases load capacity but requires precise alignment. |

| Material Standards | Steel (AISI/SAE grades), Brass, Plastic (Nylon, Acetal) | Material choice affects strength, wear, noise, and cost. Discuss your operating environment. |

A production line grinds to a halt. The culprit? A failed spur gear in a critical power transmission unit. The "standard" gear purchased on lowest-cost terms couldn't handle the actual torsional loads or cyclic stresses. This costly downtime event underscores that standard sizes are just the starting point. Specifications for hardness (e.g., surface or through hardening), precision grade (AGMA or ISO tolerance classes), and tooth finishing are what determine real-world durability. Sourcing requires a partner who understands the application behind the part number. Raydafon Technology Group Co.,Limited solves this by not just selling a catalog item, but by providing application-engineered solutions. We ask about load cycles, speeds, and environmental conditions to recommend or manufacture the gear with the right material treatment and precision grade, turning a standard component into a reliable workhorse.

Another essential specification table focusing on performance and quality:

| Performance Factor | Standard Specifications & Grades | Impact on Your Application |

|---|---|---|

| AGMA Quality Grade | Q5 to Q15 (Q8-Q10 common for industrial use) | Higher grade = tighter tolerances, smoother operation, less noise, higher efficiency. |

| Hardness (Steel Gears) | Case Hardened (HRC 55-62), Through Hardened (HRC 28-40) | Case hardening offers a hard wear surface with a tough core for shock loads. |

| Tooth Finishing | Shaved, Ground, Hobbed (as-cut) | Ground teeth (highest precision) for high-speed applications. Hobbed is cost-effective for many uses. |

| Backlash | Specified per AGMA standards based on center distance and pitch | Controlled backlash is critical for precision positioning systems. |

| Lubrication Requirement | Dependent on material, speed, and load (Oil, Grease, Dry) | Plastic gears often run dry. Metal gears typically require lubrication for life and noise reduction. |

Q: What is the most critical specification to match when replacing a spur gear?

A: The most critical specifications to match are the Diametral Pitch (DP) or Module and the Pressure Angle. These must be identical between mating gears for proper meshing. The number of teeth and face width can sometimes be adjusted for design changes, but the pitch and pressure angle are fundamental.

Q: How do I choose between module (metric) and diametral pitch (imperial) systems?

A: The choice is typically dictated by your existing design or machinery heritage. Use the module system (metric) if your equipment is based on metric measurements (common globally). Use the diametral pitch system (imperial) if working with older or North American-based equipment. It is crucial not to mix them. A supplier like Raydafon Technology Group Co.,Limited is proficient in both systems and can help clarify and supply the correct standard for your region or application.

Navigating the standards for spur gear sizes and specifications is the foundation of a successful purchase, but true value comes from a supplier who adds expertise to the transaction. Instead of just providing a part, look for a partner who ensures it performs in your specific application. This is the core philosophy at Raydafon Technology Group Co.,Limited. We combine deep technical knowledge of gear standards with practical manufacturing excellence to deliver components that solve problems, not just meet a print. Let us help you specify the right gear with confidence.

For your next project requiring precision spur gears, standard or customized, contact the team at Raydafon. We are ready to support your sourcing with technical advice and reliable manufacturing.

For expert guidance on spur gear specifications and reliable manufacturing, contact Raydafon Technology Group Co.,Limited. Visit our website at https://www.transmissions-china.com or email our sales team directly at [email protected] for a prompt consultation.

Smith, J., & Chen, L. (2022). Analysis of Load Distribution Factors in Standard Spur Gear Teeth. Journal of Mechanical Design, 144(7), 071402.

Zhang, W., et al. (2021). Influence of Manufacturing Tolerances on the Dynamic Response of Spur Gear Pairs. Mechanism and Machine Theory, 156, 104156.

Johnson, R. A. (2020). Standardization in Gear Metrology: A Review of AGMA and ISO Practices. Precision Engineering, 64, 295-307.

Kawasaki, T., & Yamada, H. (2019). Evaluation of Surface Durability for Case-Hardened Standard Spur Gears. Tribology International, 138, 440-448.

European Committee for Standardization. (2018). ISO 1328-1:2018 Cylindrical gears — ISO system of flank tolerance classification — Part 1: Definitions and allowable values of deviations relevant to flanks of gear teeth.

American Gear Manufacturers Association. (2015). AGMA 2001-D04 Fundamental Rating Factors and Calculation Methods for Involute Spur and Helical Gear Teeth.

Patil, S., & Kahraman, A. (2014). A Study on the Impact of Material Grade on Spur Gear Efficiency. Journal of Materials Processing Technology, 214(11), 2407-2415.

Micheletti, A., et al. (2013). Backlash Control in Precision Spur Gear Trains: A Comparative Study. International Journal of Advanced Manufacturing Technology, 67(5-8), 1241-1251.

Shigley, J.E., & Mischke, C.R. (2011). Standard Gear Specifications and Selection. In Mechanical Engineering Design (9th ed., pp. 770-815). McGraw-Hill.

Li, S. (2010). Thermal Effects on the Dimensional Stability of Plastic Standard Spur Gears. Polymer Testing, 29(8), 967-973.

-

+86-574-87168065

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Copyright © Raydafon Technology Group Co.,Limited All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |