About Us

Raydafon Technology Group Co.,Limited

Raydafon Technology Group Co.,Limited founded in 2005, is located in Ningbo City, one of the main manufacturers and exporters of

hydraulic cylinders in China. With high-quality products and services, we have won a trustworthy reputation with customers all over the world on the basis of mutual benefit. We firmly believe that reputation and customers are our top priority. Through 16 years of efforts, we have won the trust of customers at home and abroad. At present, Raydafon hydraulic components have been exported to more than 30 countries and regions such as the United States, Canada, Russia, Poland, Germany, Italy, France, Austria, Brazil and Colombia. hydraulic cylinder has reliable quality, stable performance and durability. It is completely interchangeable with the original parts. At the same time, through our own product designers, we can provide customized products and accept OEM orders. We will continue to develop new products and improve our services. If you are interested in any of our products or need any similar products, please contact us or visit our website for more details. We look forward to the opportunity to become your supplier in the near future.

View More

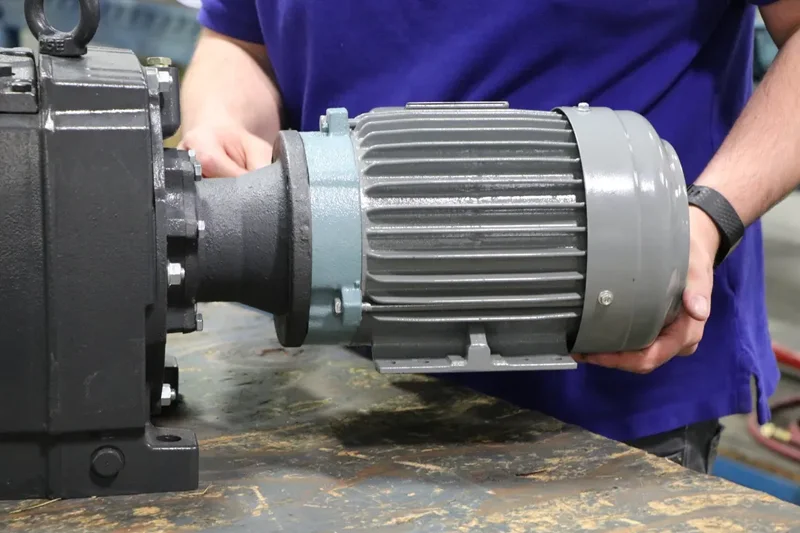

Industrial Power Transmission parts Supplier, a group of factories, Specializes in chains, sprockets, gearbox, coupling, belt pulley, motor, gear rack, PTO shaft, U-joint, buffer, rod end, ect.

Why Choose Us

-

Factory

One of the main manufacturers and exporters of hydraulic cylinders in China.

-

Experience

Through 16 years of efforts, we have won the trust of customers at home and abroad.

-

OEM & ODM

Through our own product designers, we can provide customized products and accept OEM orders.

-

Market

Exported to more than 30 countries and regions such as the United States, Canada, Russia, Poland...

News

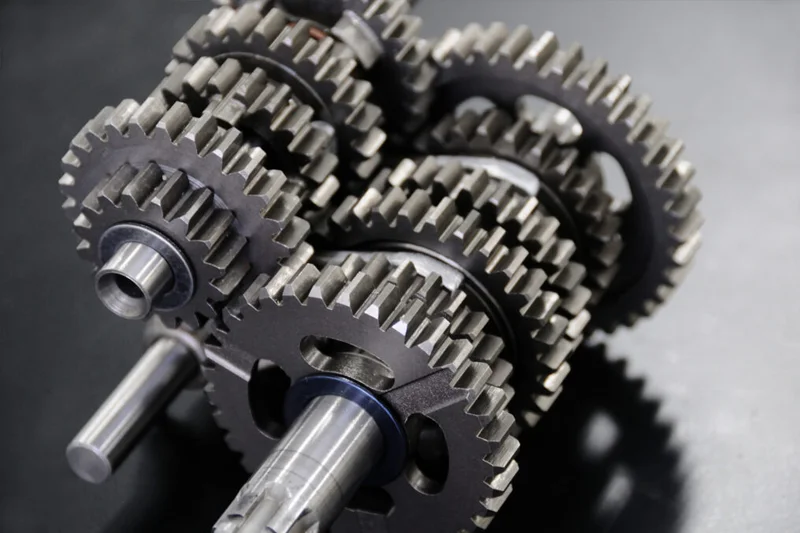

2026-01-09Precision gear ratio determines torque output and rotational speed, directly impacting system accuracy, efficiency, and performance in mechanical applications.

2026-01-07The service life of an Agricultural Gearbox is the result of multiple interconnected factors, including design integrity, material quality, load management, lubrication discipline, and environmental adaptation.

2026-01-05A worm gearbox is prized for its compact high-ratio torque multiplication, self-locking capability, and smooth operation.

2025-12-31Wear resistance is one of the most decisive factors affecting the service life, efficiency, and reliability of a Worm Gearbox in industrial power transmission systems.

2025-06-03Gears are widely used in industry, mainly for transmitting power and motion. The following are some common applications of gears in industry:

2025-06-03Gearboxes have the following advantages in agriculture:

Improve efficiency: Since agricultural operations need to adapt to different working conditions and terrains, the use of gearboxes can adjust the speed and torque of vehicles or machinery according to actual needs to improve operating efficiency.

2025-06-03Mechanical chains are widely used in the industrial and mechanical fields. Common applications include:

Conveying: Mechanical chains can be used to convey materials, products or goods, such as conveying parts on a production line.

2026-03-04Hydraulic Cylinder technology sits at the heart of this demand, serving as the primary force-transmission medium across virtually every category of powered deck equipment. Raydafon Technology Group Co.,Limited has spent years engineering these critical components specifically for the marine environment, where saltwater corrosion, dynamic loading, and continuous duty cycles create conditions that no standard industrial product can withstand.

2026-03-02Heavy-duty cylinders are not optional components in mining operations. They are mission-critical systems that directly impact productivity, safety, and cost efficiency.

2026-03-02A ring gear in a planetary gear set provides enhanced torque density, improved load distribution, and compact design, enabling efficient power transmission in various mechanical systems.

2026-02-27At Raydafon Technology Group Co.,Limited, we integrate metallurgical expertise, advanced machining technology, and rigorous inspection standards to produce high-performance Precision Gear systems tailored for industrial demands.

2026-02-27Design a screw gear for optimal performance with key engineering principles, material selection, and precision manufacturing techniques.