QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Raydafon builds gear couplings for real-world industrial use—think metallurgy mills, mining conveyors, and chemical plant pumps. What makes ours stand out? Strong load capacity, the ability to fix small shaft misalignments, and reliable performance that keeps your equipment running without hiccups. We’ve been refining these parts for years, so you get a transmission component you can count on.

Integral Gear Couplings: These are one-piece designs—no extra parts to assemble. Perfect if you’re short on space, like for small-scale fans or water pumps where every inch matters. At Raydafon, we don’t cut corners on precision here; tight machining means less energy loss and smoother operation.

Split Gear Couplings: Made of two half-couplings plus a middle connector. The best part? When you need to service your gearbox or motor, you don’t have to tear apart the whole system—just take off the split sections. We see these used a lot with big motors or heavy-duty reducers, where downtime for repairs needs to be kept short.

eneral Industrial Gear Couplings: These are our “workhorse” models. They fit most standard gear, like conveyor belts in factories or mixers for bulk materials. No fancy tweaks needed—just a straightforward coupling that handles typical speeds and loads day in, day out.

Tough-Condition Gear Couplings: For jobs where the environment is harsh—high heat from steel rolling, chemical fumes, or dusty mining sites—we use special materials and surface treatments. These couplings won’t rust or wear down fast, even on metallurgy rolling machines or chemical reactor drives.

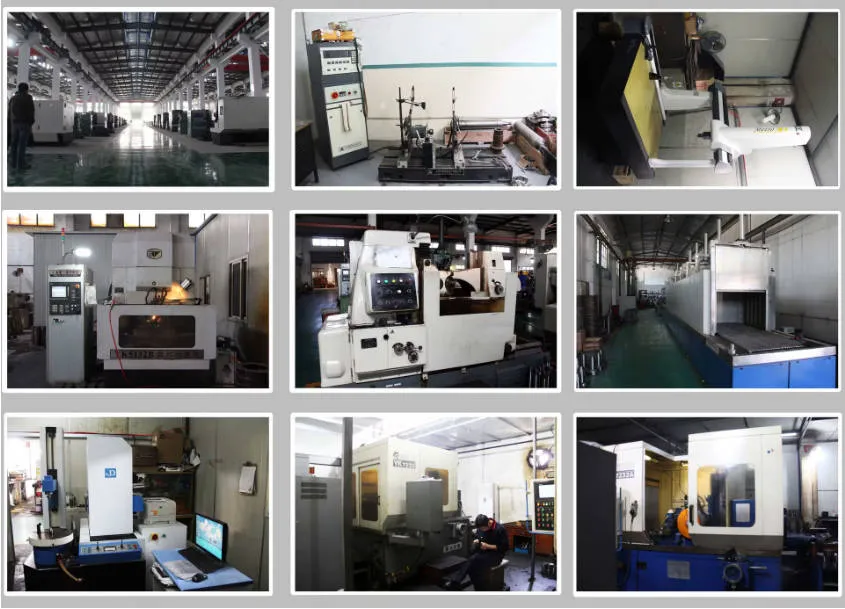

Raydafon is based in china—we’re a factory, manufacturer, and supplier all in one. That means we control quality from raw materials to finished parts, no middlemen. When it comes to price, just tell us the model, specs, and how many you need—we’ll give you a fair quote that fits your budget, without sacrificing on quality.

A gear coupling is basically a mechanical part used to link two shafts together. Its main job is to move torque from one shaft to the other, and it also helps make up for small shifts between the two shafts—like when they’re not perfectly aligned axially, radially, or at an angle. These shifts usually happen because of mistakes during installation or just normal movement when the equipment’s running. You’ll find these couplings in a lot of industrial machines that need steady power transfer, things like heavy-duty machinery, metallurgical gear, mining equipment, and even some everyday mechanical tools.

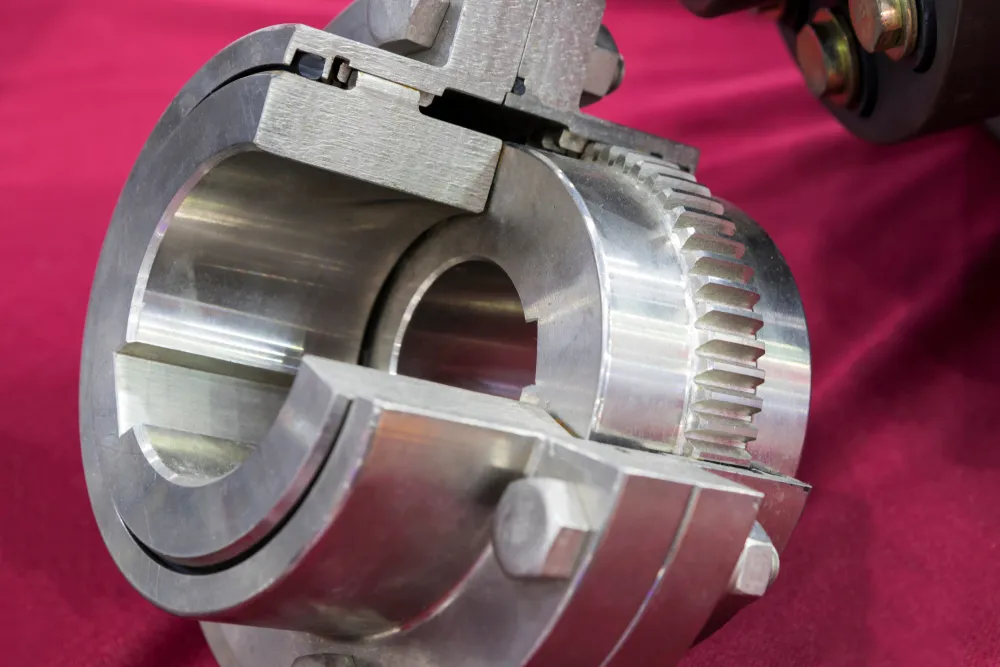

If you look at how it’s built, a typical gear coupling has two half-couplings with inner teeth and two sleeves with outer teeth. There are some special designs out there that look a bit different, but the main idea stays the same: the inner and outer teeth lock together to move power. The outer-toothed sleeves are usually attached to the shafts they’re connecting—either with a key that fits into both the sleeve and the shaft, or by being pressed tightly onto the shaft (that’s called an interference fit). The inner-toothed half-couplings are then bolted together to make a full, working part that transfers power. Here’s how it works: when one shaft spins, it turns the outer-toothed sleeve attached to it. That sleeve then spins the inner-toothed half-couplings it’s meshed with, and those half-couplings spin the other shaft. That’s how the power gets from one end to the other, keeping the whole system running.

The reason it can fix those small misalignments between shafts is all in the teeth’s shape. Most of the time, the teeth are curved (they call that a crowned tooth) or have a modified shape. This design lets the inner and outer teeth move a little relative to each other when they’re meshed. For example, if the two shafts are off a bit radially—meaning one is slightly to the side of the other—the curved teeth can slide along the width of the tooth. That way, they stay meshed properly, and the torque still gets transferred without any issues. If the shafts are at a small angle to each other (angular misalignment), the shaped teeth can adjust to that too—they keep touching the right way, so there’s less extra stress on the coupling from the misalignment.

But there are some things you need to remember when using a gear coupling. Since the teeth are moving against each other, you have to put lubricant on them regularly—gear oil works well. That lubricant does a few things: it reduces wear on the teeth, quiets down the noise when the coupling is running, and also keeps the metal from rusting and helps cool things down. If you don’t use enough lubricant, or if the lubricant gets old and stops working, the teeth will wear out faster and get too hot. Sometimes, the teeth can even get stuck together (that’s scuffing) or break, and that will mess up how the equipment runs. Another thing: when you’re installing the coupling, you should try to get the two shafts as straight and aligned as possible. Even though the coupling can fix small misalignments, if the shafts are way off—more than the coupling is designed to handle—it will add extra weight and stress to the coupling when it’s running. That makes the coupling wear out faster, and it might even damage other parts of the machine too.

Raydafon has achieved remarkable accomplishments across multiple fields and is committed to providing first-class core industrial products for the market. Its product range includes key transmission system components such as transmission parts, gearboxes, and drive shafts, as well as hydraulic cylinders suitable for agricultural and industrial applications, and pulleys of various specifications. Additionally, it offers advanced RTO environmental protection equipment, comprehensive machine tools (including CNC lathes, milling machines, machining centers, and other types), and has launched a series of high-end air compressors. This forms a complete product matrix covering application scenarios in multiple industries, capable of meeting the diverse needs of different customers in their production and operation processes.

Amid the wave of industrial development, Raydafon has always taken leading industrial transformation as its direction, continuously pursuing the layout of international expansion, making consistent progress in technological research and development, and promoting the upgrading and optimization of industrial structure. This development philosophy drives Raydafon to commit itself to innovative breakthroughs in systems, technology, and management, ultimately creating outstanding and efficient products to deliver greater value to customers. From initially being a supplier that could only provide a single type of product, Raydafon has gradually grown into a comprehensive service provider capable of offering integrated system solutions to customers, and its pioneering position in the field of automated mechanical solutions has become increasingly solid. Currently, Raydafon has built an extensive and well-established marketing network in key markets such as China, South Korea, the United Kingdom, Singapore, the United States, and Spain, fully demonstrating its adherence to outstanding quality and its firm commitment to global market connectivity.

Raydafon has always taken pride in its ability to provide personalized design and customized products according to the specific needs of customers. Relying on its excellent product performance and firm commitment to after-sales service, Raydafon has not only consolidated its market position globally but also won a good industry reputation and customer trust on the international stage.

Facing the global market, Raydafon sincerely invites potential customers and partners at home and abroad to jointly engage in productive discussions and exchanges, share important industry insights, and work together to establish stable and long-term cooperative relationships, as well as explore more development opportunities in the industrial field. As an exemplary enterprise in China's industrial sector, Raydafon is not only a reliable choice for customers but has also become a symbol of quality, continuously injecting impetus into the development of the global industry.