QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Want to purchase high-performance PTO Shaft for Discbines, Raydafon is your local trusted manufacturer and factory in China. We focus on the research and development and production of agricultural machinery transmission systems, and provide PTO universal drive shaft products suitable for various disc mowers. We are an ideal supplier choice for global agricultural machinery buyers.

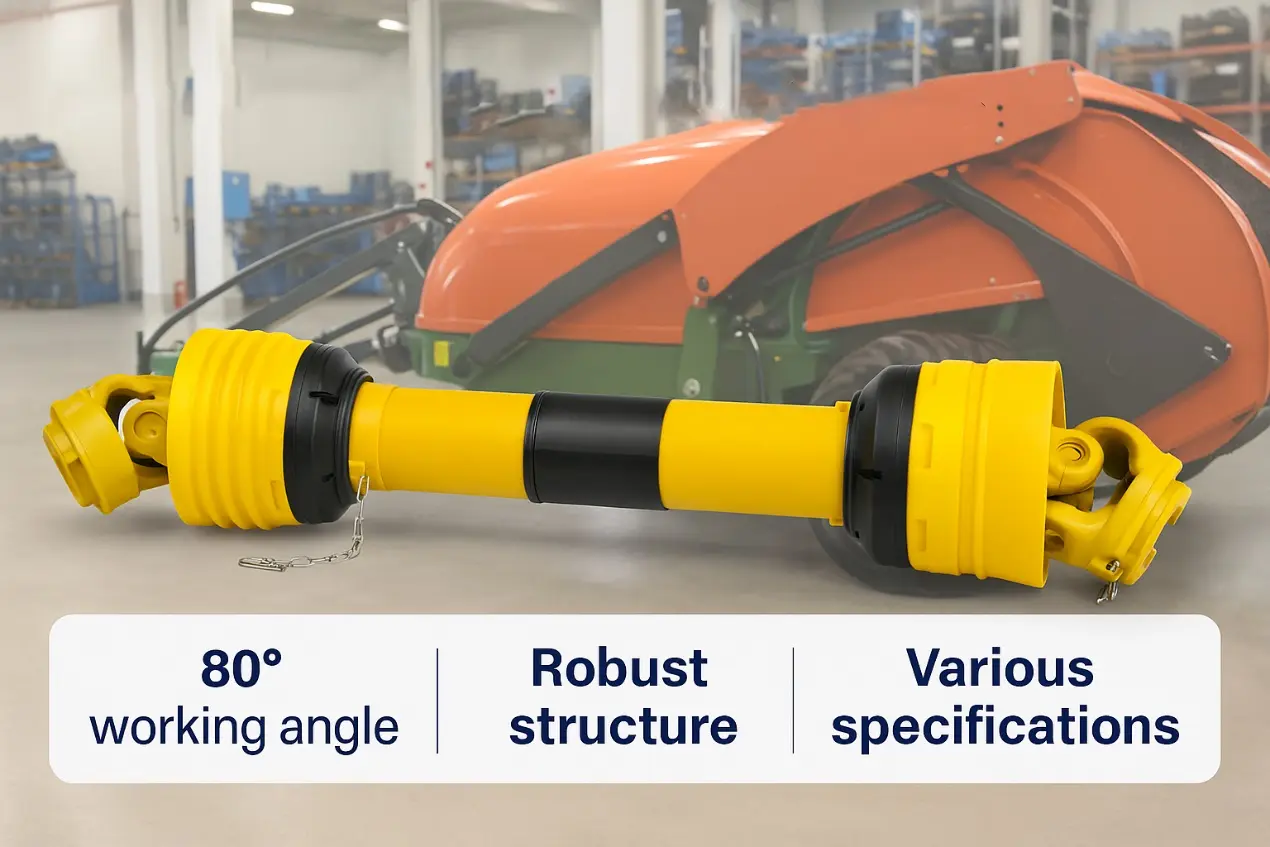

Raydafon's PTO Shaft is designed for the high-speed, high-torque, and complex-angle operation requirements of disc mowers. The product adopts a double-wide-angle universal joint structure, which can achieve a maximum working angle of 80°, ensuring that the mower's power is not interrupted when turning and operating on slopes. We use high-quality alloy steel materials, the shaft tube is heat-treated to enhance torsion resistance, and the joint is equipped with a precision forged yoke to ensure that the connection is firm and not loose under high-speed rotation. In order to adapt to the operating characteristics of frequent folding and unfolding, Raydafon PTO Shaft adopts an extended telescopic structure design, and the internal sliding tube is matched with precise clearance control to ensure smooth sliding and strong anti-jamming ability.

Raydafon's PTO Shaft for Discbines has been widely used by large farms and agricultural machinery manufacturers in Europe, America, Eastern Europe, Australia and other regions. It is used in various types of disc mowing equipment and has good market feedback and user stickiness. We have sufficient inventory for standard models and support customized drawings for non-standard products. We can quickly complete the design and delivery by only providing the main engine parameters and operating conditions. Raydafon also provides a full range of key agricultural machinery components such as worm gearbox, planetary gearbox, hydraulic cylinder, etc. Welcome to inquire for samples or test data. We will provide you with professional selection and continuous technical support.

Choosing the right PTO Shaft is the key to ensuring the safe, stable and efficient operation of agricultural machinery. As a professional manufacturer, Raydafon has summarized the following practical suggestions based on years of industry experience to help users accurately select the model according to their own equipment and working conditions.

First, it is necessary to confirm the type of agricultural machinery to be connected. Different equipment has different requirements for the structure, length, interface form, etc. of the PTO Shaft. For example: horizontal feed mixers generally require PTO Shafts with shear bolts or clutch protection; round balers are more suitable for models with cross universal joints to cope with working conditions with frequent angle changes; and for equipment such as traction fertilizer spreaders, attention should be paid to the free extension and retraction stroke of the shaft to ensure that the shaft is not broken when turning or crossing the ditch.

Secondly, the interface specifications of the power output end and the equipment input end should be matched. Raydafon offers a variety of series (such as 1-8 series) and a variety of end forms (such as 1-3/8" Z6 spline, 1-3/4" Z20 large spline, rectangular square shaft, etc.) to ensure seamless connection with various tractors and agricultural implements. When selecting, the transmission form and connection standard of the driving end and the driven end should be checked to avoid size mismatch or interference.

In addition, the torque range required for transmission should be fully considered. The load-bearing capacity of different types of PTO Shaft varies greatly. All Raydafon products are clearly marked with rated torque and maximum instantaneous impact load. For example, our 7 series PTO Shaft is suitable for equipment with a power of less than 90kW, and can withstand a maximum impact force of 2000N·m, which is suitable for operations with drastic load changes such as large balers or feed machines.

In addition, it is necessary to determine whether a safety protection structure is required. Raydafon can choose a variety of safety clutches (such as overload clutches, shear bolts, ratchet protectors, etc.) to prevent shaft breakage accidents when the equipment is abnormally blocked. For high-intensity continuous operation or use in high-risk areas, it is strongly recommended to configure corresponding protective devices.

And don't ignore the matching of the shaft length. The longer the PTO Shaft is, the better it is, but it should not be too short. The standard recommendation is that after the tractor is connected to the implement, at least one-third of the PTO shaft should be inserted into the sleeve, while retaining a free telescopic distance of 100-150mm. Raydafon can customize the telescopic stroke according to the center distance provided by the user to avoid vibration or early damage caused by length error.

Choosing the right PTO Shaft can not only improve the efficiency of mechanical operation, but also effectively reduce the frequency of maintenance and the risk of accidents. As a professional PTO Shaft manufacturer, Raydafon provides product selection solutions covering a variety of application scenarios such as feed mixers, balers, harvesters, etc. If you still have questions about the selection or need to customize the product, please contact our technical team, we will provide quick response, professional advice and actual data support.