QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

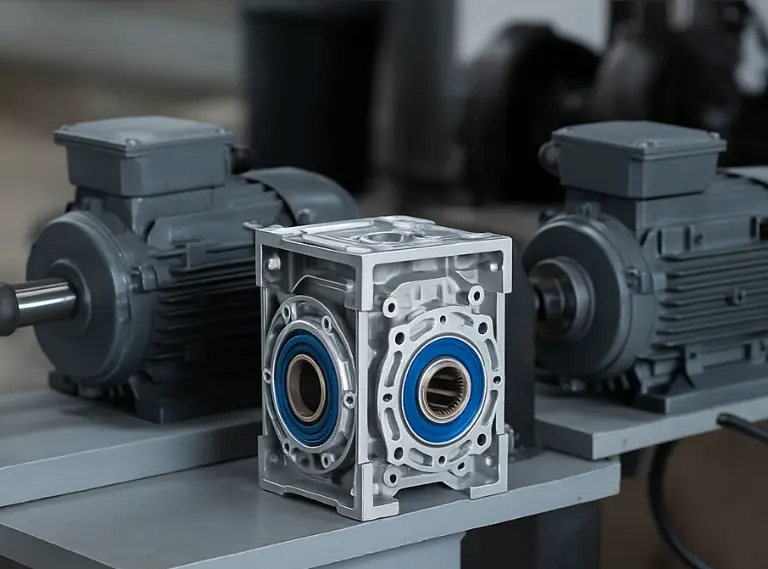

If you want to purchase high-performance worm gear and worm shaft, Raydafon, as an experienced manufacturer and factory in China, is a trustworthy choice. Relying on the advantages of the local industrial chain, we control costs from the source, keep prices within a reasonable range while ensuring quality, and as a technical supplier, we are committed to providing customers with accurate, durable, and efficient worm gear transmission solutions.

From the perspective of product structure, worm gear and worm shaft not only have a self-locking function, which is suitable for equipment such as lifting systems that need to prevent reversal, but also have a wide range of transmission ratios, which can achieve a large range of deceleration in a limited space. We provide standard models with a modulus of 1 to 10 mm and a head number of 1 to 4. At the same time, we accept drawing customization and non-standard development. The optional double-lead structure can achieve zero backlash positioning, and the accuracy is controlled within ±15 arc seconds. It is widely used in applications with extremely high transmission accuracy requirements such as robot joints, high-end testing platforms, and military and aerospace equipment.

In terms of processing technology, Raydafon strictly implements the ISO 9001 quality system, and the entire process covers blank casting, worm hobbing, heat treatment, mirror polishing, and three-coordinate detection. The worm gear ring runout is controlled within 0.02mm, and the worm lead error is ≤0.01mm, ensuring a large tooth surface contact area and high meshing efficiency. The actual test transmission efficiency can reach 92%. At the same time, the independent oil tank design extends the service life to more than 8000 hours.

Choosing Raydafon's worm gear and worm shaft means choosing a set of transmission components that can be used with confidence. Whether it is a complete machine or a spare parts replacement, we can provide you with a performance-matched, delivery-controlled solution. Welcome to contact our technical team to obtain product models and selection information, and we will develop a dedicated solution for you within 24 hours.

The worm gear and worm shaft produced by Raydafon have good compatibility. The design fully considers the mainstream reducer structures at home and abroad, which is convenient for customers to quickly replace or complete the whole machine in the existing system. Our conventional specifications of worm gear products cover M1M10, the number of worm heads can be 14, the center distance design is flexible, and it can be widely compatible with a variety of standard reducer housings and installation interfaces.

In terms of brand adaptation, our products can be directly applied to common RV reducers, NMRV reducers, WP series reducers, VF series aluminum shell reducers and other models on the market, and support the replacement of standard modules of domestic and foreign brands such as SEW, Bonfiglioli, Motovario, Tsubaki, Dongli, Quanli, etc. The worm structure of some models can also correspond to special interfaces, such as flat keys, splines or customized connection methods with end screw holes, which are convenient for quick docking with motors or output shafts.

In addition, Raydafon can make non-standard customization according to the customer's reducer size drawings to ensure that the worm lead, mounting hole position, number of teeth and other parameters correspond to the original machine one by one, so as to achieve seamless replacement. For equipment that requires compact installation or special positioning angles (such as robots, packaging machines, lifting platforms, etc.), we can also provide small-volume and high-meshing precision directional solutions. All customized products will be tested for running-in and contact points before leaving the factory to ensure that there is no interference and abnormal noise in the actual assembly process.

If the equipment you are using belongs to the above common reducer models, or there are drawings and samples for reference, we can quickly issue matching solutions and selection suggestions after confirming the interface, saving you development and debugging time. Welcome to provide your matching needs, and we will select the most suitable worm gear and worm shaft products for you.

Due to its unique meshing method, the worm gear transmission naturally has a certain self-locking ability. The key to this self-locking effect lies in the "worm lead angle" - simply put, it is the inclination angle of the worm helix. When the lead angle is less than 5°, the load cannot drive the worm to rotate in the opposite direction without external force, thus achieving mechanical self-locking. This is very useful in some equipment that needs to prevent reversal, such as elevator brake mechanisms, stage lifting platforms, valve drives, etc., to ensure that the equipment is automatically locked when the power is off or stops working to avoid sliding or malfunctioning.

However, the stronger the self-locking ability is, the better it is. It is mutually restricted by efficiency. The smaller the lead angle, the stronger the self-locking, but the transmission efficiency will also be relatively reduced; although the worm with a lead angle greater than 7° is efficient, its self-locking ability will be greatly reduced. In practical applications, Raydafon usually recommends customers to make balanced choices based on the usage scenario. For example, on equipment with large vertical loads and high safety requirements (such as hydraulic lifting systems), a single-head, small-lead worm structure can be used to enhance the self-locking effect. For automation mechanisms that require frequent start and stop, it is more suitable to use multi-head, large-lead worms to improve transmission efficiency.

In the worm gear and worm shaft product line provided by Raydafon, standard self-locking, high-efficiency and low backlash control series have been developed for different working conditions. Some models also support dual-lead structure to adjust the return clearance to ensure a more reasonable match between self-locking and response sensitivity. If you need detailed selection suggestions or test data, please feel free to consult our engineering and technical team.