QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

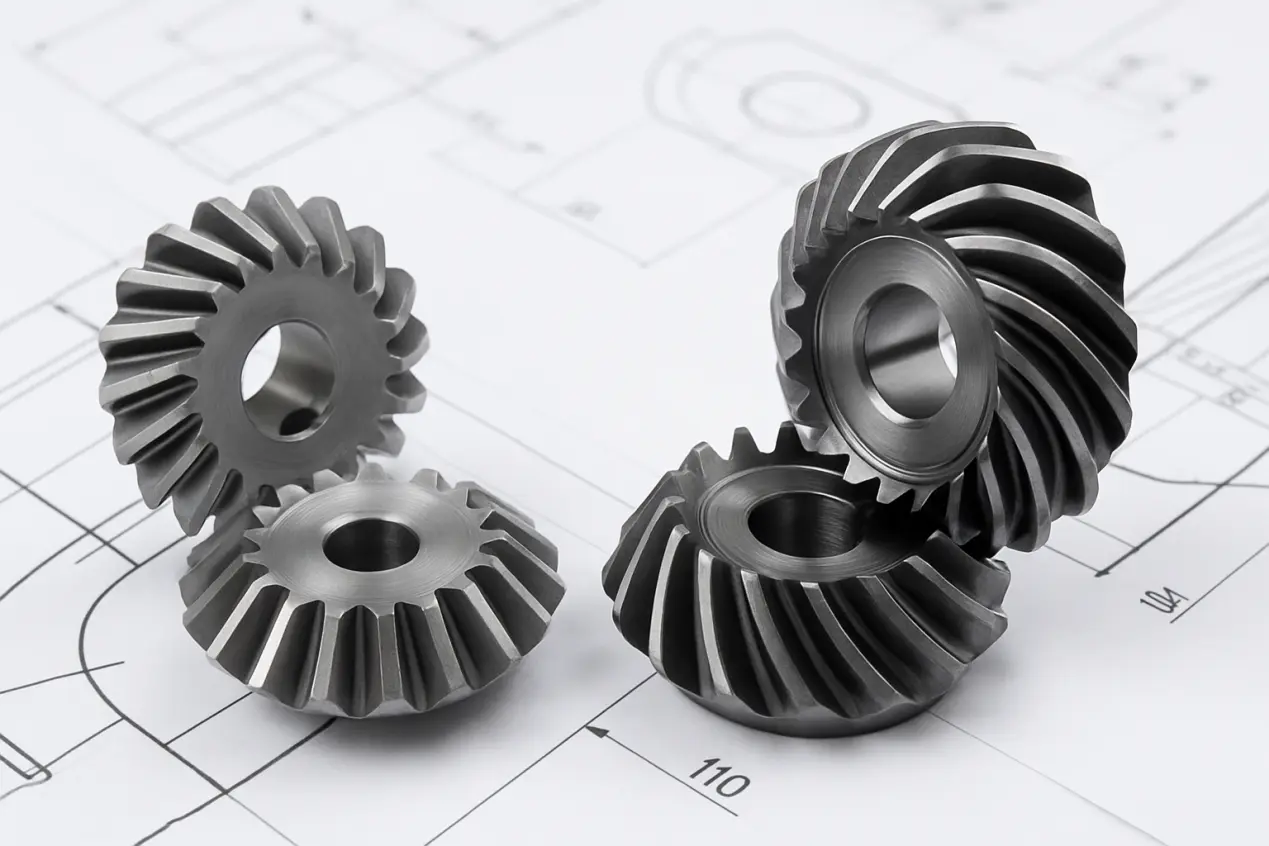

As a professional manufacturer and factory in China, Raydafon is your first choice for purchasing high-quality bevel gear! Relying on the mature local industrial cluster, we ensure product accuracy and stability while keeping prices within a reasonable range, providing global customers with products. Whether it is large-scale matching or non-standard customization, we can provide services on demand, ensure stable delivery and controllable quality, and are a bevel gear supplier worthy of long-term cooperation.

Raydafon has been focusing on bevel gear production for many years. It adopts CNC milling technology to manufacture. The tooth surface accuracy can reach ISO 6 level. It is suitable for a variety of 90° right-angle transmission occasions, such as machine tool spindles, automotive differentials, engineering machinery steering systems, packaging equipment and agricultural power machinery. Each pair of bevel gears is fully processed in our own factory, from 20CrMnTi carburizing steel cutting, gear hobbing, heat treatment, to precision gear grinding and quality inspection. We strictly implement ISO 9001:2015 quality system standards, and use the gear measurement center to detect key parameters such as pitch cumulative error and tooth shape error to ensure that the meshing clearance is stably controlled within 0.05mm.

In terms of structure, Raydafon provides two design solutions: equal height teeth and contraction teeth: equal height teeth are suitable for high-speed transmission and stable operation; contraction teeth are more suitable for high-load occasions, with a load capacity of more than 3000N·m. The tooth surface is treated with hard chrome plating, and the surface hardness reaches HRC58-62, which greatly improves the wear resistance and adapts to complex working conditions such as dust, mud, and oil. Some models adopt helical tooth design, which can effectively reduce the operating noise to below 75dB, especially suitable for industries such as medical equipment and food packaging equipment with strict noise requirements.

Whether it is a straight gear, helical gear or bevel gear, Raydafon can provide full-process technical support from design selection, parameter optimization to assembly suggestions. Please contact us to obtain selection information, quotation lists or sample models of different modules. We will provide you with technical solutions and test reports within 24 hours.

In gear selection, Miter Gear (constant speed bevel gear) and Bevel Gear (bevel gear) are often compared by customers. They are similar in appearance and are both used to achieve power transmission between two intersecting shafts, but there are obvious differences in actual usage scenarios and performance.

Among them, the biggest feature of Miter Gear is that the transmission ratio is fixed to 1:1, which means that it can only be used in systems that require constant speed rotation. It is mainly used for equipment that requires precise synchronization, such as detection platforms, optical rotating structures or some small mechanical equipment. This type of gear is simple to pair and easy to process. It is particularly popular in systems where the rotation direction changes but the speed remains unchanged.

The advantage of Bevel Gear is that the transmission ratio is adjustable. Whether it is 2:1, 3:1 or other customized ratios, it can be designed, which is very suitable for working conditions that require deceleration or acceleration, such as axles, lifting mechanisms, industrial power distribution boxes, etc. There are also more types of Bevel Gear, such as spur gear, spiral gear, zero-degree gear, etc., which can be further selected according to noise control, load capacity and other requirements.

In terms of structure, both are bevel gear structures, but Miter Gear pays more attention to angle accuracy and tooth symmetry, while Bevel Gear pays more attention to meshing strength and power carrying capacity. Therefore, when choosing, it is recommended to give priority to the transmission needs of the equipment, whether to change speed or just change direction, and then decide which one is more suitable.

Raydafon provides a variety of models of Miter Gear and Bevel Gear, with an accuracy level of up to DIN 6, and supports customization of materials such as alloy steel and stainless steel to meet the supporting needs of industrial automation, robots, agricultural machinery and other fields. If you are not sure which one is more suitable, you can also contact our technicians to provide you with application evaluation and selection suggestions.

Bevel gear is mainly used in places where two axes intersect and the direction of rotation needs to be changed. The most typical case is the transmission occasion with a 90-degree angle, such as the "L"-shaped power structure seen in many devices, and the power conversion between them is completed by bevel gears.

In the car differential, bevel gear is an indispensable part, which allows the left and right wheels to rotate freely when turning without interfering with each other. Many customers will also choose bevel gear when designing reducers or angle steering structures because it has stable transmission and takes up less space. If the equipment itself has restrictions on volume, but it needs to achieve corner output, this gear is particularly suitable.

Common industrial applications also include: small machine tools, packaging equipment, lifting platforms, mixing machinery, agricultural vehicles and construction equipment. In these equipment, not all power can be output in a straight line, and bevel gear plays the role of "turning a corner and continuing to transmit".

Different types of bevel gears are used for different loads and speeds: straight bevel gears are simple and suitable for low-speed systems; spiral bevel gears are quieter and mesh more smoothly, suitable for continuous working equipment. Raydafon offers both types of bevel gears, and the accuracy and material can be selected according to the specific working conditions.

Wherever there is power transmission between two intersecting shafts, especially in situations where the angle is limited, bevel gears are a reliable and durable mechanical option. You can tell us your equipment structure and we will help you match the most suitable specifications.