QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Raydafon, China's high-quality reducer factory direct supply, as a reliable manufacturer and supplier, we provide planetary reducers with stable performance, compact structure and reasonable price, suitable for automation equipment, high-load transmission system and precision control field, to meet the domestic and foreign customers' procurement needs for high torque, long life and high efficiency.

Raydafon planetary reducer adopts high-strength alloy steel structure, the gear is carburized and quenched and precision ground, the tooth surface hardness reaches HRC60±2, the fatigue resistance is strong, and the load-bearing capacity is much higher than the traditional gear reduction mechanism. The internal three-tooth symmetrical meshing design is adopted, the transmission efficiency can reach more than 95%, the operation is stable, the noise is low, and the torque output is uniform. It is particularly suitable for servo systems, electric cylinders, industrial robots, wheeled mobile chassis, transmission lines and lifting devices, etc., which have high requirements for precision and power response.

Raydafon Planetary Gearbox provides single-stage, two-stage, and three-stage structural combinations, with speed ratios covering 3:1~200:1, and can expand output torque and reduction ratio selection as needed; output forms include key shaft, spline shaft, flange type and customized non-standard interface to meet the installation requirements of different equipment. All products of the company have passed dynamic balancing test and concentricity test to ensure high-speed operation without shaking and heat, greatly improving the overall stability of the equipment.

The planetary reducers produced by Raydafon have been widely used in automated assembly lines, packaging machinery, CNC equipment, conveying equipment, engineering crawler chassis, wind power control systems and other fields. They have excellent performance in durability, adaptability and price competitiveness, and are well received by domestic and foreign customers. Whether you are an integrator, a complete machine manufacturer or a maintenance service provider, we can provide you with cost-effective transmission solutions and stable supply support.

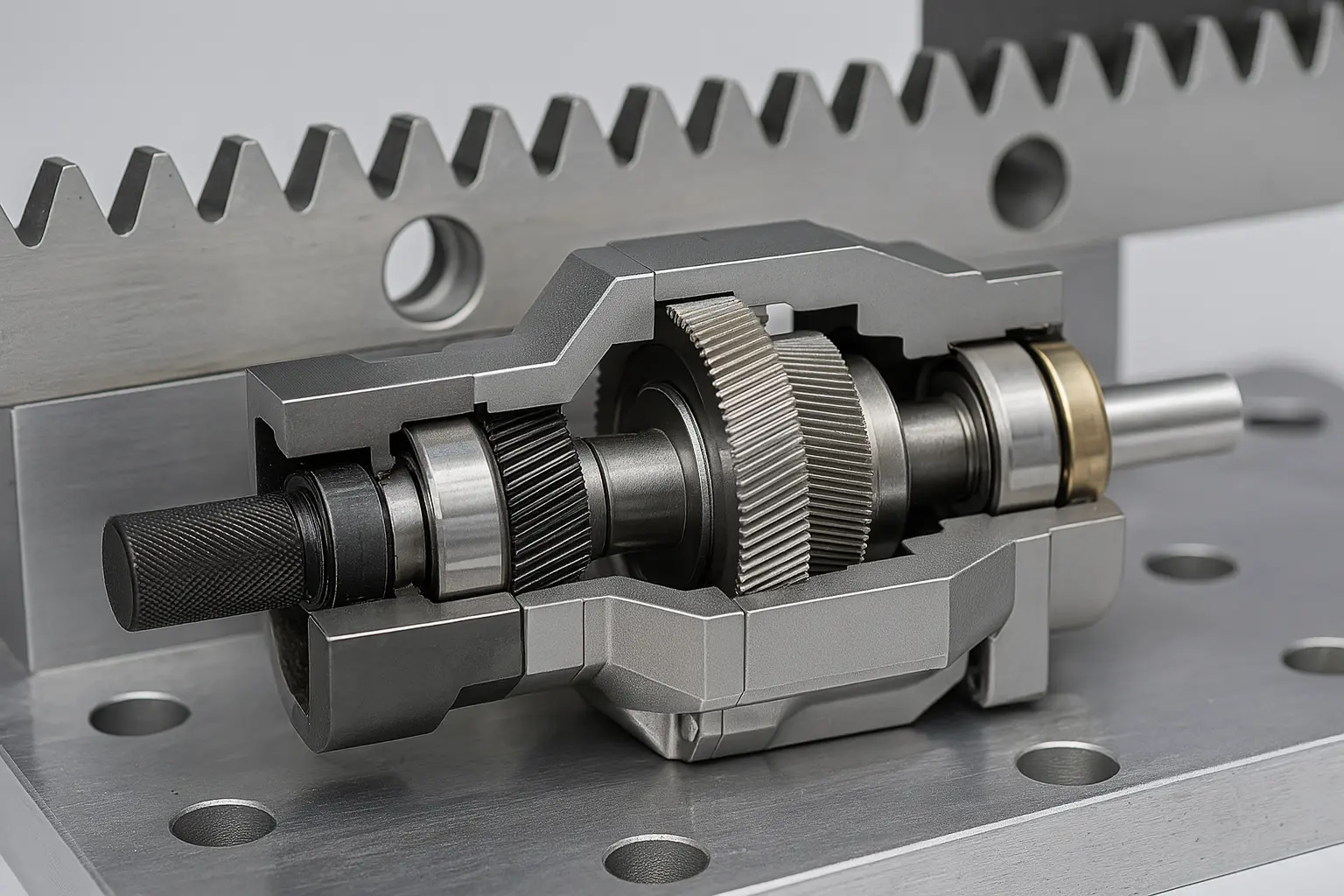

The basic structure of a planetary reducer consists of three key parts: the central sun gear (pinion at the input end), the planetary gear set rotating around it, and the inner gear ring wrapped around the outside. The power is transmitted from the motor, first driving the sun gear to rotate, and then the sun gear drives multiple planetary gears to rotate. These planetary gears rotate while revolving along the sun gear, and finally transmit the power to the output shaft through the planetary carrier fixed on them.

This "multi-tooth meshing" method allows the force to be shared among multiple gears, which not only has a smooth output and low noise, but also has a stronger load-bearing capacity than ordinary gear structures. Raydafon's planetary reducers can output higher torque under the same volume conditions, with a compact structure, suitable for equipment with limited installation space but high transmission performance requirements, such as servo systems, automated robotic arms, crawler drive modules, packaging machines, etc.

The transmission ratio of a planetary reducer depends on the gear ratio and the number of stages. Generally, a single stage can reach 310:1, a two-stage can be expanded to 20100:1, and even a three-stage combination can be made for working conditions that require a larger reduction ratio. Raydafon provides standard speed ratio structure and supports customized cascade combination, setting the output speed and torque range according to customer needs.

Because the internal planetary gear constantly changes the force position during rotation, the gear wears evenly and the whole machine has a longer life. In addition, we use hardened alloy steel gears, precision bearings and low backlash assembly standards, which makes the reducer not only stable in output, but also high in positioning accuracy, suitable for repeated start and stop, forward and reverse, and low inertia load conditions.

The core advantages of planetary reducers are high efficiency, high torque density, small size and good concentricity control. Raydafon has mature solutions in gear set design, lubrication system, output flange matching, etc., which can cover the actual needs of different industrial systems. If you are evaluating the optimization of the transmission system, we can quickly match the appropriate model and structure combination according to the motor parameters and load requirements you provide. Welcome to consult the selection.

When using or selecting a planetary reducer, the calculation of the transmission ratio (reduction ratio) is a basic and critical step. The transmission ratio determines the speed and torque of the output shaft, and has a direct impact on the equipment's operating efficiency and load matching. When designing a planetary reduction system, Raydafon will match the appropriate speed ratio structure according to actual needs to ensure stable and efficient use.

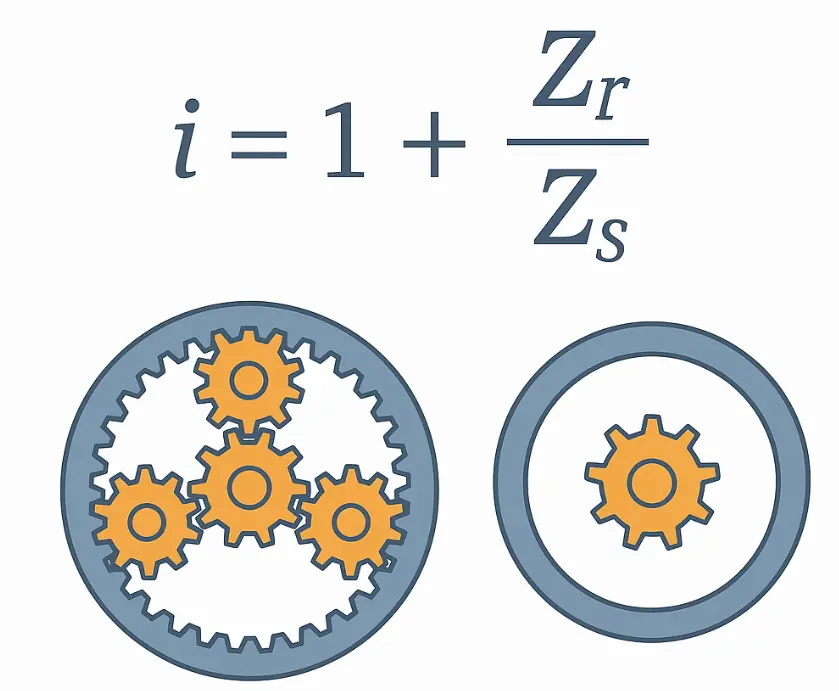

The formula for calculating the transmission ratio of a planetary reducer is actually not complicated. The most common structure is that the sun gear is active, the inner ring is fixed, and the planet carrier is output. Under this structure, the formula for calculating the transmission ratio is:

Transmission ratio i = 1 + (Zr / Zs)

Where:

Zr is the number of teeth on the inner ring

Zs is the number of teeth on the sun gear

For a simple example: If the number of teeth on the sun gear is 20 and the number of teeth on the inner ring is 60, then the transmission ratio is:

i = 1 + (60 ÷ 20) = 1 + 3 = 4

That is, the motor rotates 4 times, the output shaft rotates 1 time, and the reduction ratio is 4:1.

In the planetary reducers designed by Raydafon, the commonly used transmission ratio covers a range of 3:1 to 100:1, which is achieved through a combination of single-stage, two-stage or three-stage structures.

Single-stage structure Usually the speed ratio is 3~10

Two-stage structure Speed ratio is 15~100

Three-stage structure Suitable for heavy-load low-speed occasions that require a larger reduction ratio

In addition to calculating the speed ratio, it is also important to note that planetary groups of different levels will superimpose internal friction, which will have a slight impact on efficiency. Therefore, under the premise that the speed ratio allows, try to choose a more efficient low-level combination.

Raydafon can recommend a reasonable transmission ratio and structural level based on the motor speed, output speed requirements, load torque and other data provided by the customer, and provide parameter drawings and selection suggestions to help you avoid errors in the early stage of selection and ensure reliable operation of the equipment. If you are unsure about the transmission ratio calculation, you can also contact us directly and we will assist in calculating and matching the appropriate model.