QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

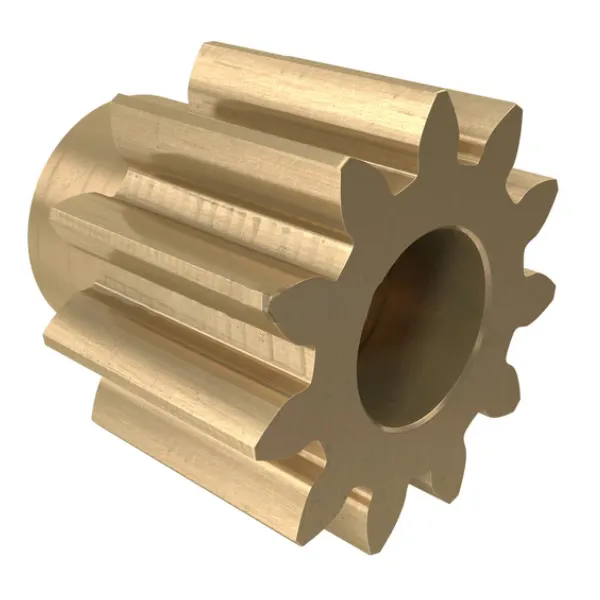

Spur Gears and Helical Gears are common gear types in mechanical transmissions. Spur gears have straight tooth profiles, with tooth flanks parallel to the gear axis. During meshing, the tooth flanks of the two gears make direct contact. Helical gears have a star-shaped helix tooth profile, with the tooth flanks forming a certain inclination angle with the gear axis. During meshing, the tooth flanks of the two gears make gradual contact. This structural difference directly leads to different transmission characteristics. Raydafon offers both Spur Gears and Helical Gears in different sizes. Welcome to purchase them.

When spur gears mesh, their entire tooth width contacts the other gear simultaneously. This contact pattern can cause significant shock and noise in the transmission. In contrast, the contact line of helical gears is inclined, significantly increasing the transmission overlap. During transmission, the meshing contact line of helical gears gradually increases and then decreases. This design reduces shock and ensures a smoother transmission.

Spur gears have linear contact with the next gear during transmission, resulting in low friction losses and high transmission efficiency, theoretically reaching 98%-99%. Helical gears, due to axial sliding friction, have lower efficiency, typically between 95% and 97%.

As mentioned earlier, the meshing contact line of helical gears is inclined, resulting in a longer length. This also reduces the unit pressure, resulting in a higher load-bearing pressure limit than spur gears. Helical gears allow for greater contact during transmission, enabling them to transmit greater torque at the same module. Their load capacity is approximately 15%-25% higher than that of spur gears.

Spur gears can typically be mass-produced using standard milling machines or hobbing machines, resulting in relatively simple processing and low manufacturing costs. However, helical gears require specialized equipment to adjust the helix angle, placing higher precision demands on the gear processing machine tools. Maintaining consistent helix angle control is particularly challenging, resulting in production costs that are 20%-40% higher than those of spur gears.

Depending on their transmission characteristics, spur gears are often used in low-speed, light-load applications, such as clockwork mechanisms, printer transmissions, and agricultural machinery gearboxes. Helical gears, on the other hand, are suitable for applications requiring higher stability or transmitting higher loads, such as automotive transmissions, industrial reducers, and marine propulsion systems.

| Feature | Spur Gears | Helical Gears |

| Tooth Design | Straight, parallel to shaft axis | Angled (helix angle, typically 15°–30°) |

| Engagement | Sudden: Full tooth contact at once | Gradual: Teeth engage progressively |

| Noise & Vibration | High (impact noise at high speeds) | Low (smooth, quieter operation) |

| Efficiency | Slightly higher (no axial thrust) | High (but reduced by thrust bearings) |

| Load Capacity | Lower (single-tooth contact) | Higher (multiple teeth share load) |

| Axial Force | None | Significant (requires thrust bearings) |

| Mounting | Simple (parallel shafts only) | Complex (needs thrust bearings) |

| Cost | Lower (easy to manufacture) | Higher (complex cutting & assembly) |

| Applications | • Low-speed mechanisms• Printers• Simple gearboxes | • Automotive transmissions• High-speed machinery• Pumps & compressors |

+86-574-87168065

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Copyright © Raydafon Technology Group Co.,Limited All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |