QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

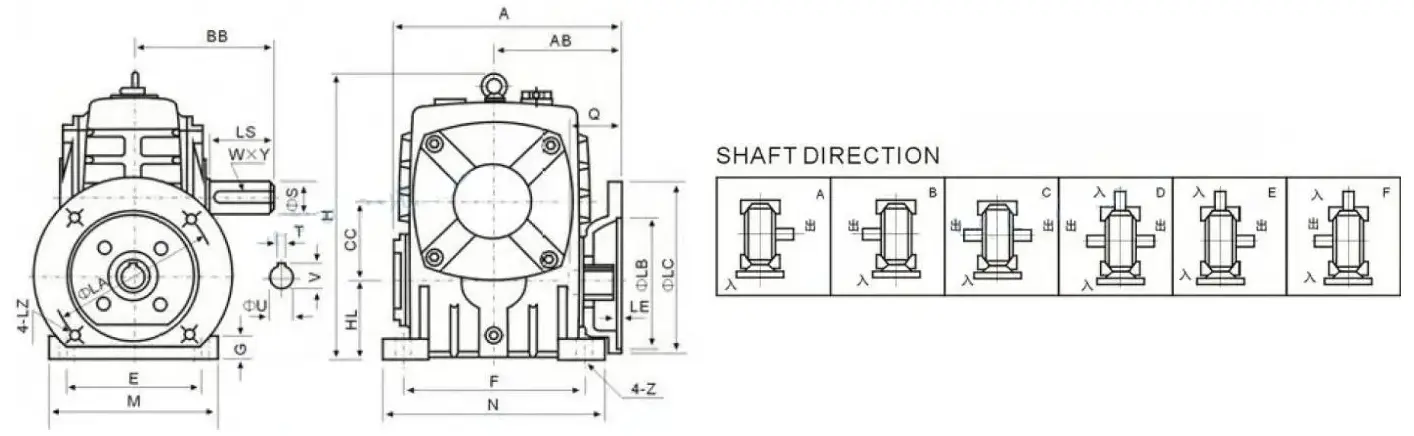

| size |

Input power (ka) |

ratio | A | AB | BB | cC | H | HL | M | N | E | F | G | Z | Flange | Input hole | Output shaft |

weight (kg) |

||||||||

| LA | LB | LC | LE | LZ | Q | U | T×V | LS | S | W×Y | ||||||||||||||||

| 40 | 0.12 |

1/5 1/10 1/15 1/20 1/25 1/30 1/40 1/50 1/80 |

135 | 75 | 74 | 40 | 138 | 40 | 90 | 100 | 70 | 80 | 13 | 10 | 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 28 | 14 | 5×3 | 5 |

| 50 | 0.18 | 151 | 83 | 97 | 50 | 176 | 50 | 120 | 140 | 95 | 110 | 15 | 12 | 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 40 | 17 | 5×3 | 8 | |

| 60 | 0.37 | 167 | 91 | 112 | 60 | 204 | 60 | 130 | 150 | 105 | 120 | 20 | 12 | 130 | 110 | 160 | 4 | M8 | 33 | 14 | 5×16.3 | 50 | 22 | 7×4 | 11 | |

| 70 | 0.37 | 200 | 109 | 131 | 70 | 236 | 70 | 150 | 190 | 115 | 150 | 20 | 15 | 130 | 110 | 180 | 4 | M8 | 40 | 14 | 5×16.3 | 80 | 28 | 7×4 | 17 | |

| 0.75 | 202 | 111 | 165 | 130 | 200 | M10 | 42 | 19 | 6×21.8 | |||||||||||||||||

| 80 | 0.75 | 225 | 125 | 142 | 80 | 268 | 80 | 170 | 220 | 135 | 180 | 20 | 15 | 165 | 130 | 200 | 4.5 | M10 | 48 | 19 | 6×21.8 | 65 | 32 | 10×4.5 | 22 | |

| 1.5 | 52 | 24 | 8×27.3 | |||||||||||||||||||||||

| 100 | 1.5 | 280 | 148 | 169 | 100 | 336 | 100 | 190 | 270 | 155 | 220 | 25 | 15 | 165 | 130 | 200 | 4.5 | M10 | 52 | 24 | 8×27.3 | 75 | 38 | 10×45 | 38 | |

| 120 | 2.2 | 333 | 181 | 190 | 120 | 430 | 120 | 230 | 320 | 180 | 260 | 30 | 18 | 215 | 180 | 250 | 5 | M12 | 63 | 28 | B×31.3 | 85 | 45 | 12×4, 5 | 64 | |

| 3.0 | ||||||||||||||||||||||||||

| 135 | 3.0 | 375 | 202 | 210 | 135 | 480 | 135 | 250 | 350 | 200 | 290 | 30 | 18 | 215 | 180 | 250 | 5 | M12 | 83 | 28 | 8×31.3 | 95 | 55 | 16×6 | 85 | |

| 4.0 | ||||||||||||||||||||||||||

| 147 | 3.0 | 415 | 235 | 210 | 147 | 480 | 123 | 250 | 350 | 200 | 280 | 32 | 18 | 215 | 180 | 250 | 5 | M12 | 83 | 28 | 8×31.3 | 95 | 55 | 16×6 | 105 | |

| 4.0 | ||||||||||||||||||||||||||

| 155 | 5.5 | 448 | 247 | 252 | 155 | 531 | 135 | 275 | 390 | 220 | 320 | 35 | 21 | 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 110 | 60 | 18×7 | 118 | |

| 175 | 5.5 | 481 | 262 | 255 | 175 | 600 | 160 | 310 | 430 | 250 | 350 | 40 | 21 | 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 110 | 65 | 18×7 | 165 | |

| 7.5 | ||||||||||||||||||||||||||

| 200 | 11.0 | 543 | 285 | 319 | 200 | 686 | 175 | 380 | 480 | 290 | 390 | 40 | 24 | 300 | 250 | 350 | 6 | M16 | 114 | 42 | 12×45.3 | 125 | 70 | 20×7.5 | 236 | |

| 250 | 11.0 | 615 | 330 | 385 | 250 | 800 | 200 | 460 | 560 | 380 | 480 | 45 | 28 | 300 | 250 | 350 | 6 | M16 | 114 | 42 | 12×45.3 | 155 | 90 | 25×9 | 396 | |

| 15.0 | ||||||||||||||||||||||||||

For the food processing industry, here are some good ways to send data quickly: The WPDA series worm gearboxes are the most important parts of the production line in the field of food packaging and mixing equipment. This is because they have high-precision transmission and self-locking performance. The original reducer didn't have enough torque, so the dough mixing equipment of a baking company got stuck. After changing the WPDA-70 model, the 40:1 reduction ratio setup made it easy for the large-capacity mixing paddle to move. When the machine is turned off, its self-locking feature keeps the mixing paddle from falling because of gravity, which keeps the equipment safe. Also, the unique sealing design of this series keeps flour dust from getting in, extends the equipment maintenance cycle to once every six months, and cuts down on the customer's downtime losses by a large amount.

Low-noise and weather-resistant options for environmental protection equipment: The WPDA series reducers are the best choice for places with a lot of humidity and corrosive materials, like sewage treatment plants and garbage sorting facilities. This is because they are very weather-resistant and quiet. Oil leaking from old-style reducers caused corrosion in the bearings at a garbage treatment plant. The WPDA-100 model's rust-proof cast iron housing and double-lip seal completely fixed the oil leak problem. The operating noise went down from 80 decibels to 62 decibels, so people wouldn't be bothered while the machine was running at night. In real-world use, the equipment has been running nonstop for 18 months without any gear wear, and the cost of maintenance has gone down by 40%, which shows that it is very reliable.

High-torque adaptation solutions for agricultural machinery: Farmers need high torque output and flexible installation design in their agricultural equipment, like combine harvesters and irrigation pumps. The WPDA series worm gearboxes meet those needs. The harvester's threshing drum didn't have enough power, so the farm had a lot of grain left over. After replacing the WPDA-80 model, the 60:1 reduction ratio made the motor torque three times stronger and the threshing efficiency 25% better. You can use the hollow shaft design directly on the original drive shaft without having to change the frame. The IP65 protection level of this series is high enough to keep field silt and rain from eroding the machinery and keep it running smoothly in difficult conditions.

Small transmission solutions for logistics and storage: The WPDA series worm gearbox are great for situations where space is limited, like automated sorting lines and lifting platforms. They make the most of the space they have by being small and modular. The logistics center replaced the original elevator reducer with the WPDA-60 model. It used the right-angle installation method to save 30% of the installation space. The 25:1 reduction ratio allowed for precise positioning, and the efficiency of sorting cargo increased by 18%. Raydafon's customized output shaft service can also perfectly match imported motors, which saves customers the cost of replacing the whole transmission system. This service has the dual benefits of being cost-effective and efficient.

The WPDA series worm gearbox housing is made of high-strength cast iron, which is impact-resistant and deformation-resistant. The internal worm gear is quenched and ground, and the tooth surface hardness reaches HRC58-62, with stable bite and long life. A customer used it on mining conveying equipment. After two years of continuous operation, the gear wear was less than 0.1 mm, which is three times longer than ordinary reducers. Moreover, this reducer has its own forced lubrication system. Even if it runs 24 hours a day, the oil temperature can be kept below 60℃, and the heat dissipation effect is excellent.

The WPDA series output torque ranges from 15Nm to 2500Nm, and the reduction ratio covers 5:1 to 100:1, which can handle light and heavy loads. Previously, there was a mixer factory with a motor power of only 1.5kW, but it needed to drive a large-capacity mixing barrel. After replacing it with WPDA-60, the reduction ratio of 50:1 directly amplified the torque to 800Nm, doubling the mixing efficiency. The customer said that this reducer is like a "strongman" installed on the equipment, which takes care of all the heavy work.

The WPDA series uses double-lip seals + dustproof skeleton oil seals, and the waterproof and dustproof level reaches IP65, and mud, rain, and dust cannot get in. A garbage treatment plant used ordinary reducers, which leaked oil and were scrapped in three months. After switching to WPDA-100, it has been running continuously for 18 months in a humid and corrosive environment. The gearbox is clean and not a drop of oil has leaked. The customer said that this reducer is like wearing a "bulletproof vest" and is as stable as an old dog under harsh working conditions.

The WPDA series supports multiple installation methods such as foot, flange, and hollow shaft, and can also customize the output shaft according to the size of the equipment, with full adaptability. A farm machinery factory wanted to upgrade its equipment, but the output shaft size of the old motor did not match. We changed the reducer output shaft for him for free, and it was sent in three days. It was installed and used directly, saving the money for changing the motor. Moreover, Raydafon provides lifelong technical support. Customers say that buying this reducer is like hiring a "24-hour nanny" and it is very reliable to use.

I am Emma Wilson, a customer from Sydney, Australia. I have been using your WPDA series worm gearboxes in my local food processing plant for almost a year. This product has really solved our previous big problems. The gearboxes we used before were particularly prone to rust in the humid food workshop, and we had to shut down for maintenance frequently. Since we switched to your WPDA series, even though we were dealing with flour and moisture all day, the aluminum alloy material of the gearbox housing has not rusted at all, and the bronze worm gear inside is still as bright as new. There is almost no noise during operation, and we no longer have to worry about affecting the food testing equipment in the workshop. There was a time when I needed to adjust the reduction ratio. Your customer service not only patiently explained to me the difference between different models, but also took the initiative to help me do the load calculation. After the recommended model was installed, it really ran very smoothly, and the production efficiency was greatly improved.

My name is James Carter, and I am a Raydafon customer. Thank you so much for the WPDA series worm gearbox products you sent! I used them in my project and found that they worked very well, were very reliable, and were also very efficient. We really appreciated how carefully your company designed its products and how easy they are to install and maintain. Your service is also very good. From the first consultation to the delivery, everything went smoothly, and it was easy to talk to you. I want to keep working together in the future, and I'll tell other partners about your products!

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Tel

+86-574-87168065

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Copyright © Raydafon Technology Group Co.,Limited All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |