QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

If you want to purchase high-performance Spur Gear, Raydafon, as a professional manufacturer and factory in China, is a trustworthy supplier. Relying on China's mature local gear manufacturing system, we control the price within a reasonable range, and strictly control the processing and testing process to provide stable and reliable spur gear solutions for global customers.

Raydafon has been focusing on the design and manufacturing of Spur Gear for more than 20 years, and has a complete production system and R&D capabilities. The product is mainly made of 20CrMnTi alloy steel, processed by multiple processes such as CNC hobbing, carburizing quenching and precision grinding, and the tooth profile accuracy reaches ISO 6 level, ensuring smooth meshing, low vibration and low noise during the transmission process. Our products can be used in a variety of working environments such as medium and high speeds, low loads to high loads, and is especially suitable for linear transmission scenarios in industries such as automation equipment, packaging machinery, CNC machine tools, textile equipment and conveying systems.

If you need more model specifications, price information or 3D drawings, please feel free to contact our technical team. We will provide the most suitable solution according to your needs.

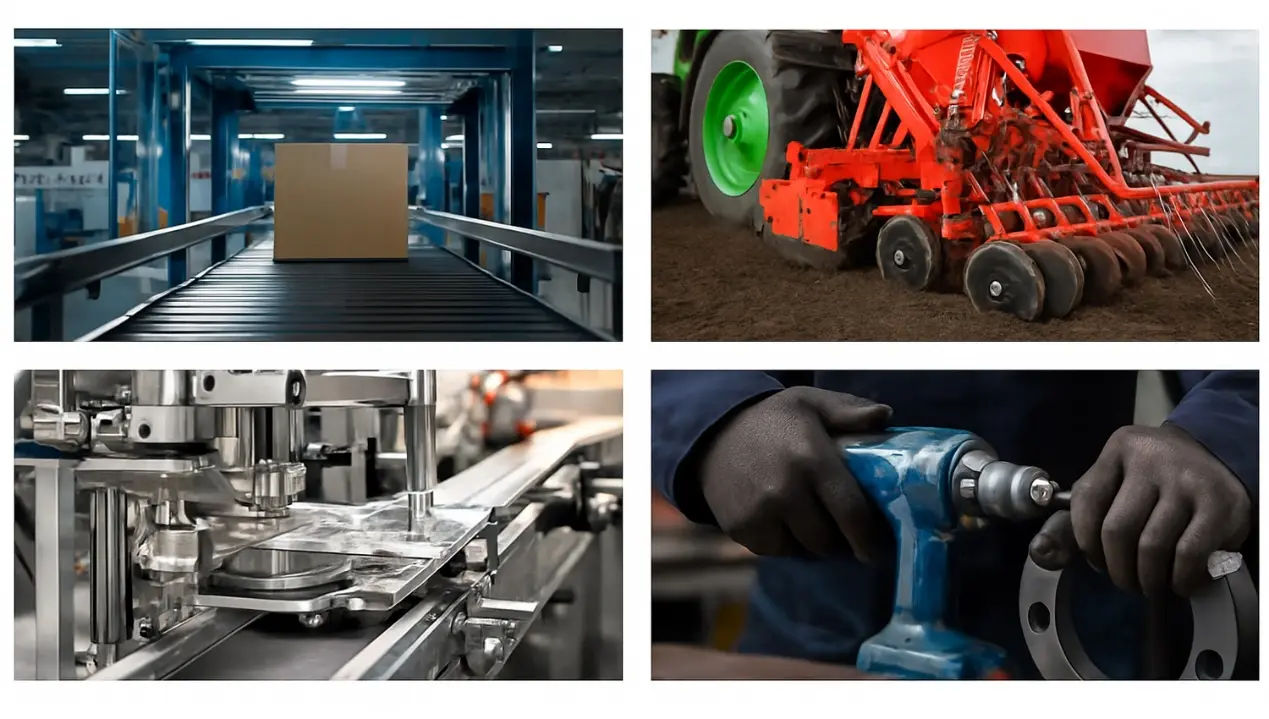

Spur gears are an indispensable part of many mechanical equipment. They are often used in places where power needs to be transferred from one parallel axis to another, such as conveying equipment, packaging machinery, agricultural tools, electric machinery, etc. in factories. Because of its simple structure, high transmission efficiency and convenient maintenance, it is widely used.

In practical applications, such as a conveyor on an automated assembly line, the spur gear is responsible for driving the roller to rotate so that the goods can move forward smoothly; for example, on an agricultural seeding machine, they participate in controlling the sowing rhythm to ensure uniform operation; even in some common power tools, it can be seen, playing a key role in transmitting power.

The spur gears provided by Raydafon can adjust the size, material and number of teeth according to specific needs, such as carbon steel, stainless steel or plastic materials, etc., to adapt to various scenarios. Some customers have reported that after replacing the original parts with our customized spur gear, the noise has been reduced a lot and the wear has been slower. For many users, spur gear is not the most complicated part, but if used properly it can make the entire equipment run more stably and the cost more controllable.

Measuring Spur Gear is a hands-on and careful job. Although this type of gear has a simple appearance, it is easy to have problems with poor fit or transmission if you don't master a few key methods.

Usually, the first thing you need to determine is the number of teeth, which is more intuitive. Just count the teeth one by one. Then comes the module, which is not a dimension that can be measured directly. The most common practice is to first measure the outer diameter of the gear with a caliper, and then estimate the module based on the number of teeth. For example, if the outer diameter of a 20-tooth gear is about 42 mm, then the module is about 2.

Next is the tooth width, which can be measured directly with a vernier caliper. This size is related to the load-bearing capacity of the gear. If it is too narrow, it may not be stable enough, and if it is too wide, it will waste materials. The tooth height is usually divided into the tooth top height and the tooth root height. For simplicity, you can also look at the entire tooth profile height. It will be more accurate to use a projector or a gear gauge.

Another thing that is easily overlooked is the tooth thickness, which can be measured with a micrometer or a special tooth thickness gauge. This data determines whether the gear can mesh smoothly. In addition, if higher precision is required, the tooth profile angle and pressure angle must be considered. Most standards are 20 degrees, but if it is to replace old parts, some are 14.5 degrees. At this time, you can't just rely on the naked eye to judge, you need to use professional measuring equipment, such as imagers or three-coordinate measuring instruments.

In actual work, we at Raydafon often receive samples sent by customers, some of which are old gears removed from equipment, and some are new projects with incomplete drawings. We usually help customers do a full-size survey first, and then provide supporting design suggestions. If you encounter a situation where the gear cannot be measured accurately and you don't know how to choose, you are also welcome to contact us to figure things out together.

When choosing a basic and key component like spur gears, many customers are concerned about stability, durability, and whether they can be used on their equipment for a long time without problems. Raydafon has been making spur gears for many years. We don't do fancy publicity, but only focus on one thing: making the gears solid. Our spur gears are all produced in our own processing factories. The tooth surface processing is clean, the tooth shape is standard, and the meshing is smooth. Whether it is on a low-speed conveyor line or a high-speed motor drive, it can work stably.

The materials we use are all selected, such as 20CrMnTi carburized steel or quenched and tempered steel. After heat treatment, it has high strength, is not easy to wear, and will not deform easily. These gears are mostly used in packaging machines, agricultural machinery, and automation equipment. The most common point of customer feedback is "it's worry-free to install it." Many old customers continue to repurchase because they have used it for several years without any problems.

In addition to spur gear, we also make agricultural gearbox, planetary gearbox and PTO shaft. Many customers give us the entire transmission system. First, the matching is good, and second, if there is any problem, we can connect with one factory, which is convenient.

In short, if you are looking for a batch of durable, highly compatible and stable delivery spur gear, Raydafon is a safe choice. We do not emphasize "high technology", but we make real products that can be implemented, loaded and used for a long time. Welcome to contact us for samples or parameter details.