QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

The WPA series worm gearbox adopts an integrated cast iron housing design with a compact structure and high strength, which is especially suitable for industrial scenarios with limited space. Its worm gear has been processed by precision grinding technology, which greatly improves the meshing accuracy and improves the transmission efficiency by about 12% compared with traditional models. This series can easily adapt to a variety of equipment needs from light to heavy loads. For example, in food packaging machinery, low reduction ratio models can drive high-speed sealing mechanisms; while in mining conveying equipment, high reduction ratio models can stably output high torque to ensure that the equipment continues to operate under harsh working conditions.

To meet the installation requirements of different equipment, the WPA series provides multiple forms such as foot installation, flange installation, hollow shaft output, and supports customized output shaft size. For example, an environmental protection equipment factory needs to directly connect the reducer to an imported motor, but the motor output shaft diameter does not match the standard model. We adjusted the input shaft diameter and keyway position to complete customized production in just 5 days, avoiding the cost of customers replacing the entire transmission system. In addition, the series is compatible with a variety of power sources such as three-phase asynchronous motors and servo motors, with strong adaptability and can be quickly integrated into existing production lines.

The WPA series reducer reduces the operating noise to below 65 decibels by optimizing the worm helix angle and tooth surface hardness, which is especially suitable for scenarios with high requirements for quietness, such as textile machinery and medical equipment. The gear adopts carburizing and quenching process, and the surface hardness reaches HRC58-62, which significantly improves the wear resistance and can maintain the transmission accuracy even in the face of frequent start-stop or impact loads. A customer of an automated production line reported that after using the WPA series, the equipment has been running continuously for 2 years without gear wear problems, and the maintenance cost has been reduced by about 40%.

Compared with imported brands, the WPA series worm gearbox is about 30% lower in price while ensuring performance, and the delivery cycle is shortened to less than 15 days, which is particularly suitable for small and medium-sized enterprises with limited budgets but pursuing efficiency. As a professional manufacturer, Raydafon provides full-process services from selection guidance to after-sales maintenance, such as providing customers with free technical support such as torque calculation and installation drawings, and promises to respond to after-sales problems within 24 hours. This combination of high cost-effectiveness and high-quality services makes the WPA series the first choice for many customers to upgrade their equipment.

|

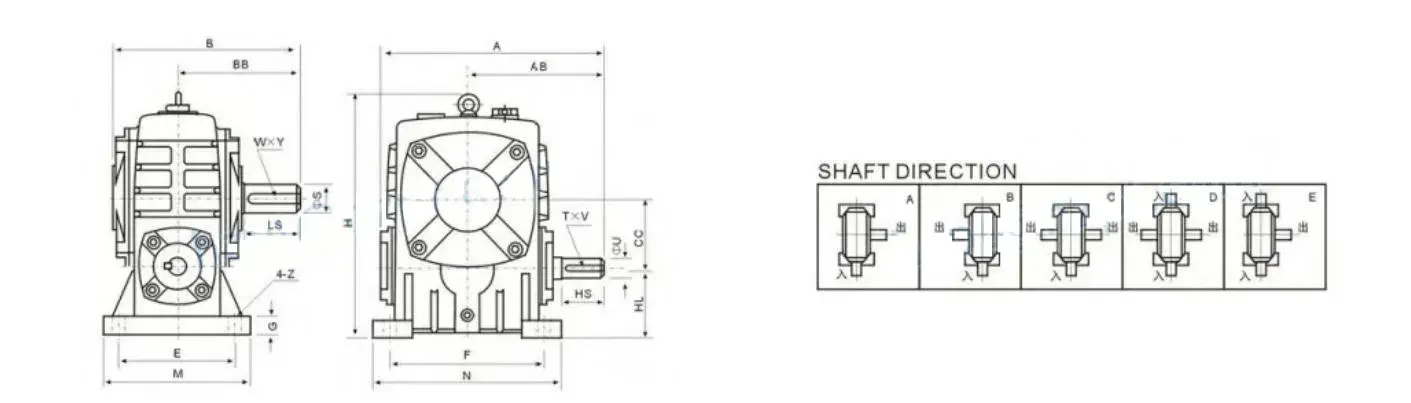

size |

ratio |

A | AB | B | BB | CC | H | HL | M | N | E | F | G | Z | inputshaft | output shaft |

weight (kg) |

oil level (L) |

||||

| HS | U | TXV | LS | S | W×Y | |||||||||||||||||

| 40 |

1/5 1/10 1/15 1/20 1/25 1/30 1/40 150 1/60 |

143 | 87 | 114 | 74 | 40 | 138 | 40 | 90 | 100 | 70 | 80 | 13 | 10 | 25 | 12 | 4×2.5 | 28 | 14 | 5×3 | 4 | 0.13 |

| 50 | 175 | 108 | 150 | 97 | 50 | 176 | 50 | 120 | 140 | 95 | 110 | 15 | 12 | 30 | 12 | 4×2.5 | 40 | 17 | 5×3 | 7 | 0.17 | |

| 60 | 198 | 120 | 168 | 112 | 60 | 204 | 60 | 130 | 150 | 105 | 120 | 20 | 12 | 40 | 15 | 5×3 | 50 | 22 | 7×4 | 10 | 0.22 | |

| 70 | 231 | 140 | 194 | 131 | 70 | 236 | 70 | 150 | 190 | 115 | 150 | 20 | 15 | 40 | 18 | 5×3 | 60 | 28 | 7×4 | 15 | 0.60 | |

| 80 | 261 | 160 | 214 | 142 | 80 | 268 | 80 | 170 | 220 | 135 | 180 | 20 | 15 | 50 | 22 | 7×4 | 65 | 32 | 10×4.5 | 20 | 0.85 | |

| 100 | 322 | 190 | 254 | 169 | 100 | 336 | 100 | 190 | 270 | 155 | 220 | 25 | 15 | 50 | 25 | 7×4 | 75 | 38 | 10×4.5 | 35 | 1.50 | |

| 120 | 371 | 219 | 282 | 190 | 120 | 430 | 120 | 230 | 320 | 180 | 260 | 30 | 18 | 65 | 30 | 7×4 | 85 | 45 | 12×4.5 | 60 | 3.20 | |

| 135 | 422 | 249 | 317 | 210 | 135 | 480 | 135 | 250 | 350 | 200 | 290 | 30 | 18 | 75 | 35 | 10×4.5 | 95 | 55 | 16×6 | 80 | 3.60 | |

| 147 | 432 | 256 | 320 | 210 | 147 | 460 | 123 | 250 | 350 | 200 | 280 | 32 | 18 | 75 | 35 | 10×4.5 | 95 | 55 | 16×6 | 98 | 3.70 | |

| 155 | 497 | 295 | 382 | 252 | 155 | 531 | 135 | 275 | 390 | 220 | 320 | 35 | 21 | 85 | 40 | 12×5 | 110 | 60 | 18×7 | 110 | 3.80 | |

| 175 | 534 | 314 | 388 | 255 | 175 | 600 | 160 | 310 | 430 | 250 | 350 | 40 | 21 | 85 | 45 | 14×5.5 | 110 | 65 | 18×7 | 150 | 4.60 | |

| 200 | 580 | 342 | 456 | 319 | 200 | 666 | 175 | 360 | 480 | 290 | 390 | 40 | 24 | 95 | 50 | 14×5.5 | 125 | 70 | 20×7.5 | 215 | 6.50 | |

| 250 | 703 | 420 | 552 | 385 | 250 | 800 | 200 | 460 | 560 | 380 | 480 | 45 | 28 | 110 | 60 | 18×7 | 155 | 90 | 25×9 | 360 | 9.00 | |

The WPA series worm gear reducers are particularly outstanding in scenarios such as automated packaging and assembly lines. For example, in the filling equipment of food processing plants, the reducer drives the conveyor belt to run at a stable speed by reducing the motor speed and amplifying the torque, ensuring the precise positioning of bottled products. Its self-locking characteristics can also prevent the conveyor belt from reversing due to inertia or load changes, ensuring production safety. A beverage company reported that after using the WPA series, the equipment failure rate was reduced by 60%, and the product defective rate was reduced by 15% due to the smooth transmission. In addition, the series supports linkage with the PLC control system, which facilitates enterprises to realize intelligent production scheduling.

In environmental protection fields such as sewage treatment and garbage disposal, the WPA series reducers have become the first choice due to their low noise and corrosion resistance. For example, in sludge mixing equipment, the reducer needs to operate in a humid and corrosive environment for a long time. Its cast iron casing has been rust-proofed and combined with the sealing ring design, it can effectively prevent water vapor and impurities from invading and extend its service life. The measured data of a sewage treatment plant showed that after 12 months of continuous operation, the internal gear wear of the WPA series reducer was only 1/3 of that of ordinary models, and the operating noise was always controlled below 65 decibels, avoiding interference to surrounding residents.

Mining equipment has extremely high requirements for the torque output and reliability of the reducer. The WPA series can easily cope with heavy-load scenarios by optimizing the worm gear design. For example, in the transmission system of the ore crusher, the reducer needs to withstand frequent impact loads. Its high-hardness gears and forced lubrication system can ensure stable power transmission and reduce downtime and maintenance time.

The WPA series worm gearbox is also widely used in agricultural equipment, such as driving the threshing drum of the combine harvester or the water pump of the irrigation system. Its modular design supports multiple installation methods and can be quickly adapted to different models of agricultural machinery. According to feedback from an agricultural machinery cooperative, the WPA series reducer performs stably under complex working conditions in the field. Even in the face of impurities such as mud, sand, and straw, its sealing structure can still keep the lubricating oil clean, avoiding gear damage caused by lubrication failure. In addition, this series supports customized output shafts, which can be seamlessly connected to old agricultural machinery, helping farmers save equipment upgrade costs.

My name is James Carter, and I am from a small machinery manufacturing company in Australia. We used to be troubled by the noise and stability of the equipment transmission system, until we tried Raydafon's WP Series Worm Gearbox, which completely changed my mind! After the installation of this reducer, the equipment ran significantly smoother, and the previous "buzzing" harsh sound was almost inaudible. The workers said that the operating environment was much more comfortable. What surprised me even more was its durability - our factory is dusty and humid, and ordinary reducers leak oil or jam within a few months, but Raydafon's reducer has been used for almost a year, and the gear meshing is still smooth, and the maintenance cost has been directly reduced by half. Now all the company's new equipment has been replaced with Raydafon reducers, and even old customers have praised the improved quality of our equipment. I sincerely recommend it to all friends who need a reliable transmission solution!

I am Ruben Janssen from the Netherlands. The old conveyor equipment on the farm was always broken. After replacing it with Raydafon's WP Series Worm Gearbox, it was like breathing new life into the machine! The biggest headache before was the gearbox oil leakage and noise. After your product arrived, I paid special attention to the workmanship of the seal ring. The rubber parts are soft and elastic, and they fit tightly during installation. Last week, when debugging the equipment, we encountered a problem with the motor matching. The technician drew the assembly drawing and emailed it overnight, and even the bolt torque was clearly marked. Now the conveyor starts and stops smoothly, and even the feed bags on the conveyor will not fall over. The energy consumption meter shows that the power consumption has been reduced by 15% compared with before.

I am Mark Schneider, a customer from Germany. I have been using your WPA series worm gearboxes in the Port Logistics Center of Hamburg for almost two years. I must tell you about the surprises brought by this product. We have used gearboxes of various brands before, and they always had problems under high load and frequent start-stop conditions. I didn’t expect that the WP series completely withstood the test - even when continuously handling 40-foot containers, the gearbox did not slip or heat abnormally. During the high temperature operation throughout the summer last year, the shell temperature was always controlled within 60℃, which was nearly 20℃ lower than the previous equipment. Last month, a colleague from Rotterdam came to visit and asked for your contact information on the spot after seeing the operating effect of the WP series. I sincerely thank you for providing such reliable products and services. Now our logistics center has listed Raydafon as the preferred brand for the new equipment bidding. I look forward to continuing to cooperate with you in the future, and I wish your company more and more success in the European market!

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Tel

+86-574-87168065

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Copyright © Raydafon Technology Group Co.,Limited All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |