QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Raydafon's Ring Gear series includes internal gear rings, segmented gear rings, large modulus heavy-duty gear rings and other types, which are widely used in slewing bearings, wind power yaw systems, engineering machinery turntables, heavy-duty transmission devices and other fields. Raydafon, as a professional manufacturer and factory in China, is your first choice!

We use high-strength alloy steel as the basic material, combined with CNC gear hobbing, gear grinding and other processing processes to ensure that the tooth surface finish and meshing accuracy meet industry standards. For large-size Ring Gear, we are equipped with a dedicated heat treatment line, which can achieve full-circle carburizing or induction quenching treatment to improve fatigue strength and wear resistance. All products are fully produced in our own factories, and key parameters such as pitch error and radial runout are detected by three-coordinate, gear profile measuring instruments and other equipment to ensure smooth assembly and no abnormal noise during operation.

At present, Raydafon's Ring Gear products have been widely used in tower cranes, shield machines, automated workstations and other equipment, and exported to Germany, Brazil, India and other countries. With stable quality and timely delivery, we have won long-term cooperation with many equipment manufacturers at home and abroad. Whether you need a small batch of samples for trial installation or bulk purchase, Raydafon can provide solid support for your project with professional services and excellent products. Feel free to contact us for samples or quotations, and our technical team will provide quick response and selection suggestions based on your drawing requirements.

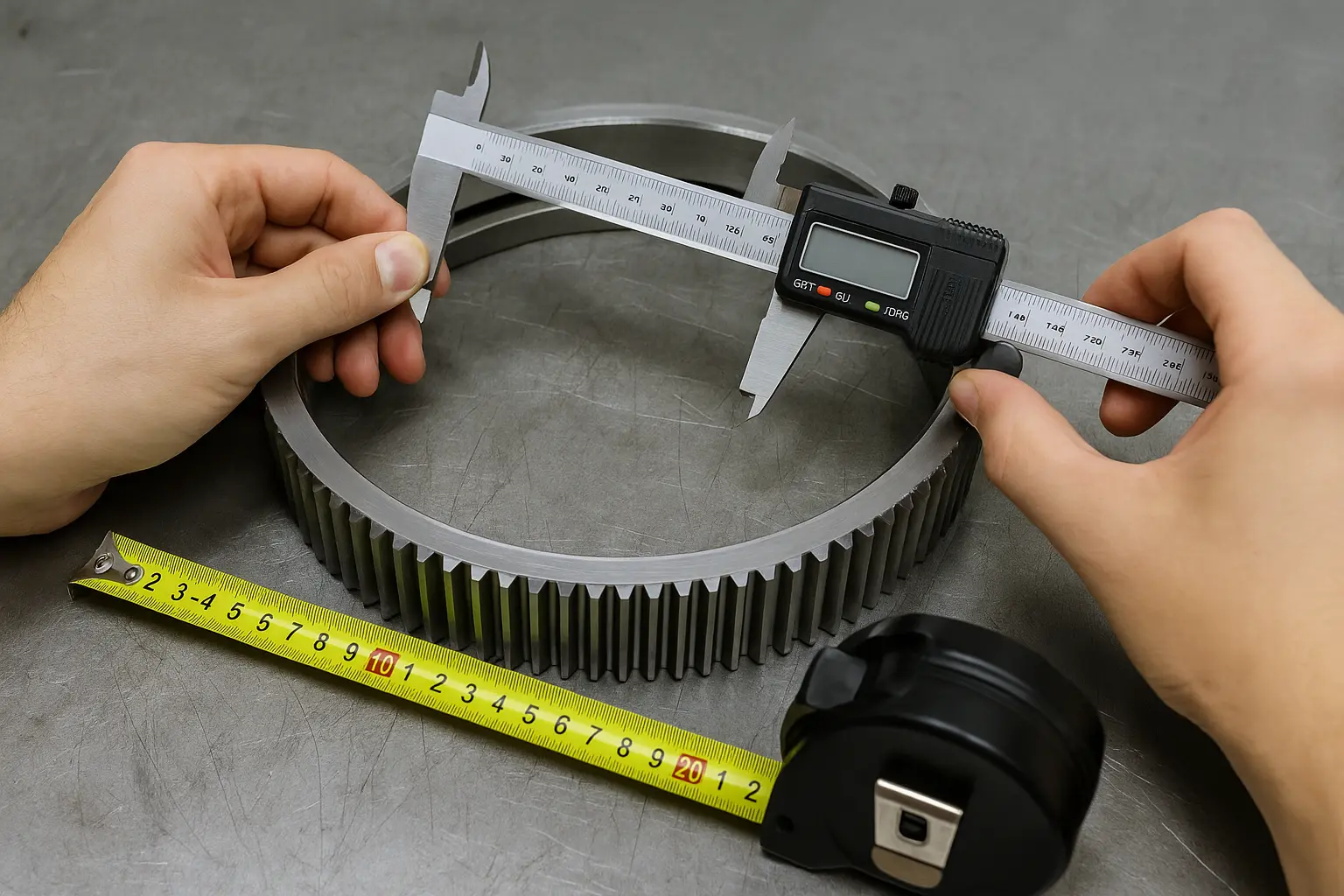

Many customers often don't know where to start measuring when replacing or customizing Ring Gear (gear ring). In fact, this work is not complicated. As long as you master a few key size parameters, you can determine whether it matches the needs of the equipment.

First look at the outer diameter.

Use a caliper to measure the distance from the outermost edge of the gear ring to the outermost edge, which is the so-called "outer diameter". This value determines the space occupied by the gear ring in the overall structure. It cannot be too large or too small, and it must fit the position of your original equipment.

The second is the inner diameter.

This is the diameter of the circular hole in the middle of the gear ring. Some customers call it the "shaft hole". This size must be completely consistent with the shaft or flange at the installation position on your equipment, otherwise it will not fit or will be loose.

Next is the number of teeth.

Just count the teeth one by one, it's not complicated. This value will affect the proportional relationship of the gear transmission. If it does not correspond to the matching sun gear and planetary gear, the equipment will not operate normally.

The module is also critical.

The module is the size of each tooth, which is related to the distance between teeth. This can be calculated using the formula: Module = Outer diameter ÷ (Number of teeth + 2). If you are not sure, you can tell us the number of teeth and outer diameter, and we will help you calculate.

There are also tooth width and tooth angle.

Some equipment is sensitive to noise and load, so you need to consider the tooth width (thickness of the teeth) and pressure angle (the inclination of the teeth, generally 20 degrees). These affect the smoothness of meshing and are also related to life.

If the ring gear has screw holes, remember to measure the hole spacing and thread specifications.

Some Ring Gears have screw holes for fixing. Measure the size, number and arrangement circle (PCD) of the holes and send them to us, so that we can quickly confirm whether it is universal or whether the mold needs to be modified.

Choosing Raydafon's Ring Gear is essentially choosing a reliable, high-precision transmission solution that can withstand long-term load tests. Raydafon specializes in the manufacture of various precision gears. With a mature production system and extreme control of details, our ring gear products are not only of stable quality, but also have good versatility and compatibility. They are widely used in core transmission structures such as wind power speed increasers, planetary reducers, and engineering machinery drive systems.

Our Ring Gear is made of carburized alloy steel, high-strength cast steel or customized stainless steel materials, and is precision forged and heat treated according to the usage scenario. The tooth surface hardness can reach up to HRC60. In terms of technology, we use multiple precision processing links such as CNC hobbing, tooth profile trimming, and ring gear inner diameter lapping, and use the gear measurement center to fully inspect key dimensions such as tooth direction error and radial runout to ensure that each product can achieve high matching and interference-free operation with the planetary carrier and gear shaft.

Raydafon is well aware that different industries have different requirements for ring gear products, so we provide a variety of specifications and non-standard customization services. From large modulus heavy-duty ring gears to small modulus high-precision ring gears, we can produce on demand and deliver samples as soon as 10 working days after the drawing is confirmed. At the same time, our Ring Gear also supports internal and external gear structures, which can meet the structural requirements of various working conditions such as wind power yaw mechanisms, automatic transmission boxes, and mechanical slewing devices.

Raydafon not only produces Ring Gear, but also has a complete Precision Gear product line, including Plastic Gear, Bevel Gear, Screw Gear, etc. Whether it is a customer who pursues quiet and lightweight office equipment, or an industrial customer who requires heavy-duty and wear-resistant, we can provide a one-stop solution. Choosing Raydafon means choosing a technical manufacturer that truly understands gears, controls costs, and does not compromise on quality. If you have technical questions about the application of ring gears, or are looking for high-precision ring gears that are suitable for a certain device, please feel free to contact our technical team. Raydafon will provide a stable and reliable "power closed loop" for your transmission system.