QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Raydafon, as a major gear manufacturer rooted in China, is experienced in plastic internal gear manufacturing. With the exquisite craftsmanship of our own factory, the gears we produce are not only of excellent quality, but also at a reasonable price. Let's take a look at where these gears come in handy.

Plastic internal gears play an important role in automotive electronics. For example, products from Raydafon are found inside the adjustment system of a car seat. It is small enough to fit into the narrow space of the seat frame, and through precise transmission, it allows the seat to realize flexible adjustment of the angle of the front, rear, and backrest. Moreover, the plastic material is non-conductive, so there is no risk of short circuits when it is used in the vicinity of automobile circuits.

It is also essential in the field of office equipment. Printer feeding system on the plastic internal gear “power”, it can be a stable transmission ratio, the paper one after another accurately into the print channel to avoid paper jams. Like the auto document feeder of some high-end MFPs, this gear is also needed to ensure the smoothness of document scanning and transmission, and Raydafon's products make the office environment quieter by virtue of their low-noise characteristics.

In smart home products, the product is the core of the smart trash can opener. When it senses proximity, the gear begins to work, silently driving the lid open. Our gears are self-lubricating and do not require frequent maintenance, so even if they are opened and closed dozens of times a day, they will last for years. There are also smart blinds, which realize blade angle adjustment through gear transmission and control light entry, bringing convenience to home life.

For medical equipment, such as the airflow adjustment component of a small portable ventilator, plastic internal gear is used, which meets the standards of medical grade materials, does not release harmful substances, and has a high transmission precision to precisely control the airflow according to the needs of the patient.The gears produced by Raydafon undergo a number of quality control processes, and are highly stable, which guarantees the reliable operation of the medical equipment. This ensures the reliable operation of medical equipment. As a factory-direct supplier, we offer high-performance products to a variety of industries at affordable prices.

| Dimension | Φ60mm |

| Module | M0.15-M2.0 |

| Material Type | POM, PA, PPA, PBT PEEK as customized |

| Meshing Grade | ISO6, JGMA 1, JIS 6, AGMA 13, DIN 6, Din5, AGMA12 |

| Application | Automotive, Military, Aircraft, Mechanical, industrial, Medical |

| Customized | ODM/OEM supported |

| Sample | Sample available |

| Modes of Packing | Vacuum-packed with Plastic Tray |

| Modes of Delivery | DHL UPS |

| Certificate | ISO 9001: 2008/TS16949 |

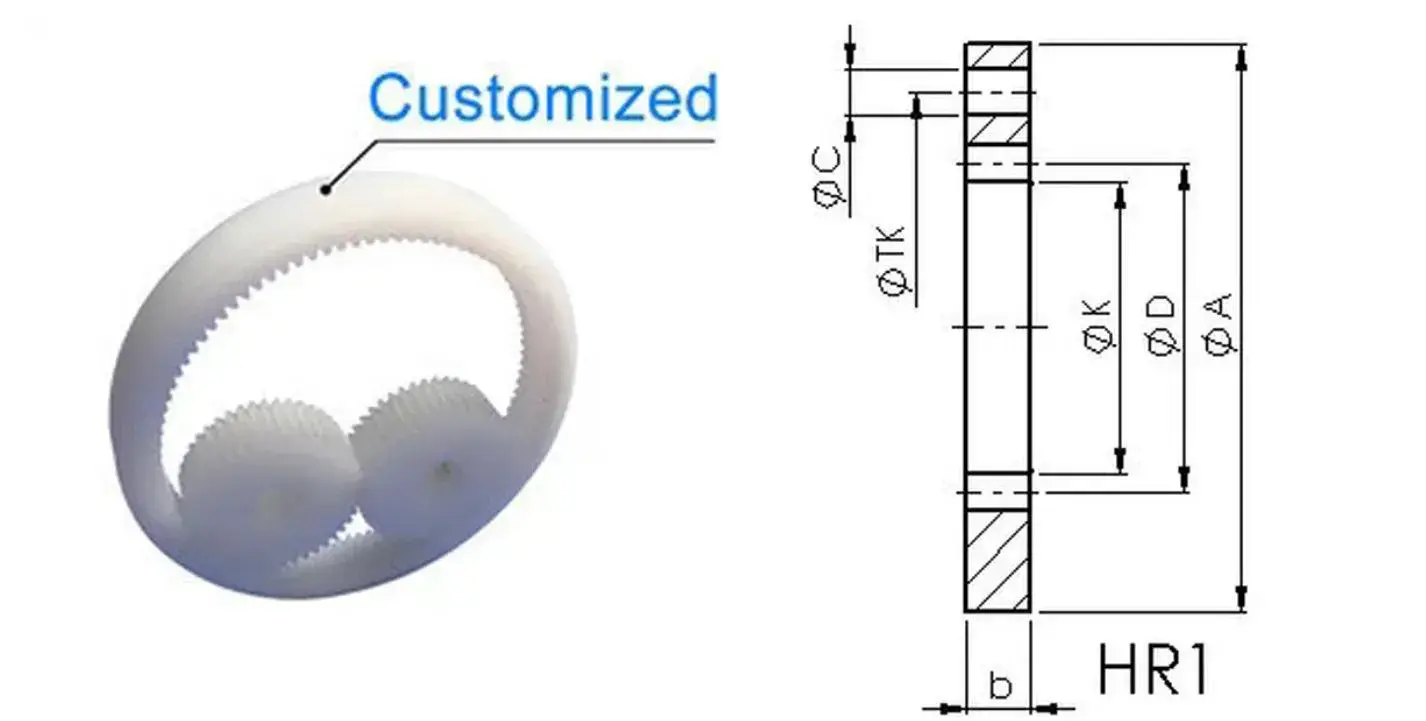

Pressure angle: 20 °

Material: POM-C natural

Mechanically manufactured toothing,

excellent quality.

Helix angle: 0 ° (straight flanks)

| Part no | Number of teeth | b | A. | øD | OK | øC | øTK |

| Items: |

|

[mm] | [mm] | [mm] | [mm] | [mm] | [mm] |

| HR1-20 | 20 | 5 | 35 | 20 | 18 | 2.8 (3x) | 29 |

| HR1-30 | 30 | 5 | 45 | 30 | 28 | 2.8 (3x) | 39 |

| HR1-40 | 40 | 5 | 55 | 40 | 38 | 2.8 (3x) | 49 |

| HR1-50 | 50 | 5 | 65 | 50 | 48 | 2.8 (3x) | 59 |

| HR1-60 | 60 | 5 | 75 | 60 | 58 | 2.8 (6x) | 69 |

| HR1-70 | 70 | 5 | 85 | 70 | 68 | 2.8 (6x) | 79 |

| HR1-80 | 80 | 5 | 95 | 80 | 78 | 2.8 (6x) | 89 |

| HR1-90 | 90 | 5 | 105 | 90 | 88 | 2.8 (6x) | 99 |

| HR1-100 | 100 | 5 | 115 | 100 | 98 | 2.8 (6x) | 109 |

| HR1-110 | 110 | 5 | 125 | 110 | 108 | 2.8 (6x) | 119 |

| HR1-120 | 120 | 5 | 135 | 120 | 118 | 2.8 (8x) | 129 |

| HR1-130 | 130 | 5 | 145 | 130 | 128 | 2.8 (8x) | 139 |

| HR1-140 | 140 | 5 | 155 | 140 | 138 | 2.8 (8x) | 149 |

Other sizes are possible on request, as well as the production of plastic internal gear rings according to drawings.

Space utilization "Little Expert": Plastic internal gear's unique internal gear structure is like "slimming down" the transmission system. In the folding wing transmission device of the drone, it can compress the originally bulky transmission structure into a palm-sized space. The gears produced by Raydafon have a tight internal gear bite through precise mold design, and the drone will not fall off even if it is frequently folded and unfolded.

Quiet operation "Top student": The advantages of plastic internal gear are fully demonstrated in the library's intelligent bookshelf mobile system. When readers search for books, the bookshelf moves slowly and almost no sound is heard. We use specially formulated plastics, and the tooth surface is polished very smoothly, which reduces the noise by 60% compared to metal gears, "escorting" a quiet reading environment.

Anti-corrosion and moisture-proof "Tough guy": In the automatic feeding machine of aquaculture, the humid environment is a big test for the gears. They are naturally resistant to water and corrosion. The gears produced by Raydafon are made of high-strength weather-resistant plastic. Even if they are exposed to fish and shrimp feed and water mist for a long time, they will not deform or rust, ensuring the stable operation of the bait thrower throughout the year.

Cost control "Money-saving genius": When toy factories mass-produce remote control cars, they can save a lot of costs by choosing Raydafon's products. It has fast injection molding and does not require complex processing technology. As a supplier that ships directly from the factory, Raydafon's large-scale production keeps the price to the lowest. Toy manufacturers can get wear-resistant and durable gears at an affordable price, and the product cost performance is instantly improved.

I am Emily Carter from GreenTech Innovations in the United States. When I was developing a new environmental protection equipment, I couldn't find a suitable internal gear, which almost blocked the project progress. I contacted Raydafon with a try-it attitude, and you not only quickly recommended the appropriate plastic internal gear, but also helped to optimize the design.

This gear is a perfect match for the equipment, with amazing transmission efficiency and energy consumption reduced by 20% than expected. The best thing is that after working continuously for a month in a humid environment, there is no sign of corrosion at all. This performance is beyond my imagination! Now the project is progressing smoothly and the customer has been giving good reviews, thanks to your reliable products and super professional services! We will definitely cooperate for a long time in the future!

I am James Wilson from a British company. In order to solve the problem of equipment lightweighting and noise, I tried many internal gears from other companies, but none of them were ideal until I used Raydafon's products. When it was installed on the equipment and running, the quiet and smooth feeling was like replacing the machine with "silent tires", and the weight was much lighter than metal gears, making it much easier to carry and install. The key is that the durability exceeded expectations. After three months of high-intensity operation, there were no burrs on the tooth surface. From answering questions tirelessly during selection to coordinating logistics in advance during delivery, your team's meticulous service has completely conquered me. You are definitely a trustworthy and high-quality partner!

I am Lena Müller from Germany. I never thought that buying a gear could be such a worry-free experience! When we were developing new equipment, we had extremely high requirements for the precision of plastic internal gear. Many products on the market did not meet the standards. When we almost gave up, we met Raydafon. Your technical team not only helped me make an adaptation plan overnight, but also took the initiative to send samples for testing first.

In actual use, the meshing accuracy of this gear is simply amazing. There is not even an error of 0.1 mm when the equipment is running, and there is no problem of tooth skipping at all. What touched me even more was the after-sales service - once the equipment suddenly broke down, I sent a message for help in the early morning, and you immediately arranged an engineer to guide the investigation through video, and the problem was solved in less than half an hour. Now this gear has become the "golden partner" of our equipment. I will identify your company for future purchases and will also recommend it to my German counterparts!

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Tel

+86-574-87168065

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Copyright © Raydafon Technology Group Co.,Limited All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |