QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Raydafon focuses on the research and development and manufacturing of PTO Shaft products and has rich experience in the field of agricultural transmission systems. As a professional manufacturer from China, our own factory is located in the agricultural equipment industry cluster area, and we implement full-process quality control from material procurement, forging processing to assembly. We provide a full range of PTO Shafts, suitable for a variety of agricultural machinery and equipment, such as mowers, rotary tillers, fertilizer spreaders, crushers, etc., and our products are exported to many developed agricultural markets such as Europe, America, the Middle East, and South America.

The design focus of Raydafon PTO Shaft is "safety, versatility, and durability". Each drive shaft is made of high-strength carbon steel pipe and equipped with forged steel forks. It has high strength and high torque, and can maintain long-term stable operation in heavy-load and high-frequency operating environments. We also provide a variety of international standard specifications according to the usage habits of different regions, such as Italian CE type, German WAL type, American ASAE standard, etc., to meet the interface compatibility requirements of agricultural machinery of different brands.

In terms of safety, Raydafon PTO Shaft comes standard with a safety cover and torque-limiting clutch device to effectively avoid overload damage and personal injury caused by equipment jamming. Some high-end models also support quick plug-in and pull-out structures, which facilitates quick replacement and repair of agricultural machinery outdoors, greatly improving work efficiency.

The lubrication hole position is reasonably designed, and with the sealing structure, it can effectively extend the lubrication cycle and reduce the workload of daily maintenance. The products are subjected to dynamic balancing tests and strength impact tests before leaving the factory to ensure that each set of PTO Shaft will not produce abnormal vibrations at high speeds, thereby improving the durability and safety of the overall transmission system.

As a professional supplier that has long served agricultural machinery OEMs and retail channels, we are well aware of the differences in the application of PTO Shaft by users in different industries. Raydafon supports sample customization and batch non-standard production, with flexible delivery cycles, and the technical team can assist users in matching selection and interface matching design. Standard models are always in stock and can be shipped on the same day to minimize user delivery time.

At present, Raydafon PTO Shaft has been widely used in medium and large agricultural machinery, garden equipment, livestock feed machinery and other fields, providing stable and reliable transmission support for customers at home and abroad. If you have specific application needs, please contact us to obtain drawings, specification manuals or sample testing support, and we will tailor a suitable transmission solution for you. Choosing Raydafon means choosing a stable, safe and easy-to-maintain core connection for agricultural machinery power.

In the daily maintenance of agricultural machinery, it is not complicated to remove the PTO drive shaft, but if it is not done properly, it is easy to damage the interface components and even bring safety hazards. Before disassembly, the most important step is: be sure to turn off the power source first and ensure that the equipment is completely shut down before you can start the operation.

First observe the connection method between the drive shaft and the gearbox. Most PTO Shafts shipped by Raydafon use a structure with a safety lock, and there is usually a push-type retaining ring or latch near the end of the gearbox. Some models are fixed with screws, and tools such as hexagonal or plum wrenches are required at this time.

When disassembling, grab a section of the protective cover near the gearbox with your hand and carefully pull it back to expose the connection mechanism inside. If it is a button retaining ring type, press the retaining ring with one hand and gently pull the drive shaft out with the other hand to separate it; if it is a screw type, after unscrewing the fixing screw, pull it out gently.

Do not pull violently or shake too much during operation to avoid damaging the gear spline or bearing oil seal. Sometimes, after the equipment has been used for a long time, the interface may rust and get stuck. In this case, you can first spray some lubricating rust remover, wait a few minutes, and then slowly try to pull it. If it is really difficult to disassemble, you can use a rubber hammer to gently tap the edge of the shell twice to help it loosen.

After removing the drive shaft, it is recommended to check whether the spline interface has burrs, wear or deformation. If you find a problem, don't install it hard. It is best to replace the accessories before using it. The PTO Shaft and Gearbox produced by Raydafon have standard interfaces. As long as the direction is aligned, they can be installed back without brute force.

If you encounter uncertain structures or jams during the disassembly process, please contact Raydafon's technical support. We can provide structural drawings or video guidance based on the model you have, to help you quickly complete the disassembly and assembly without delaying farming arrangements.

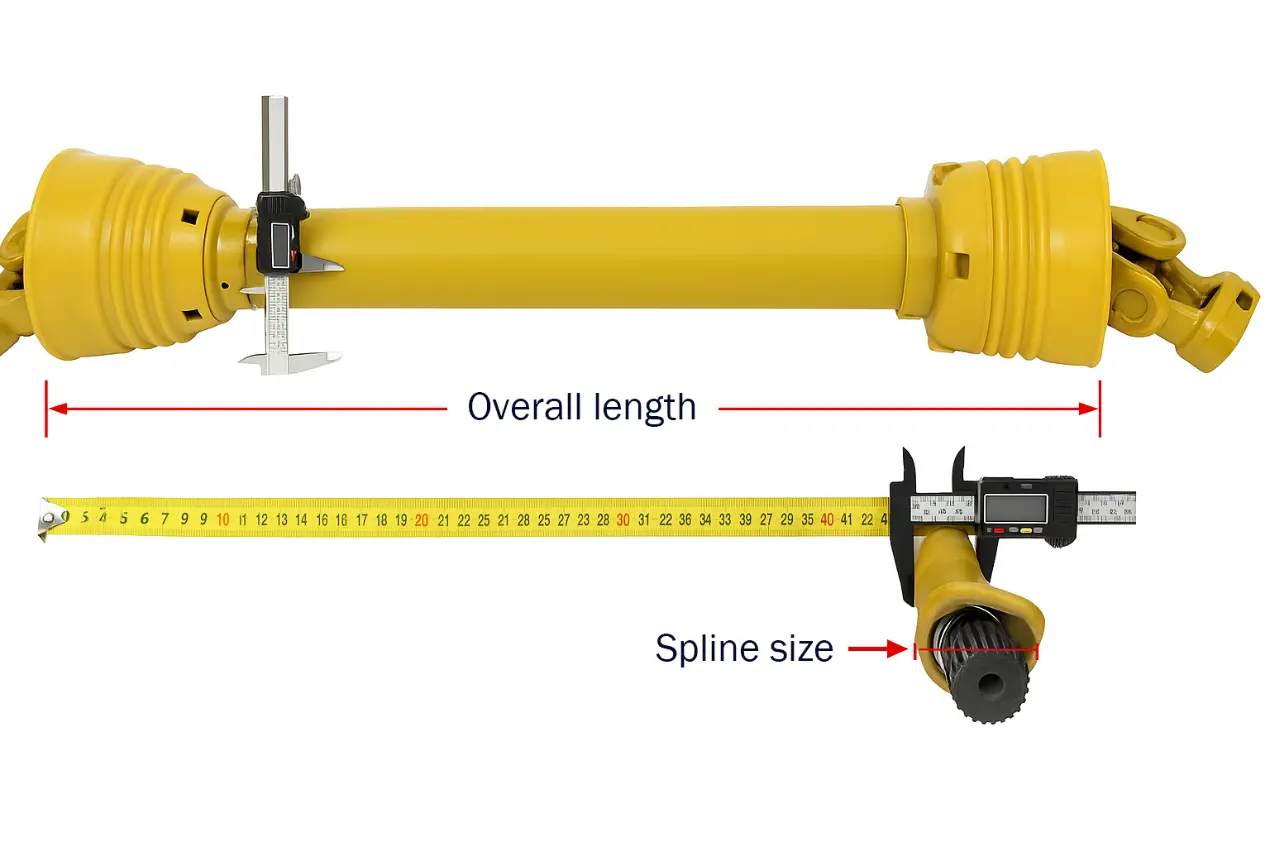

Before replacing or customizing a PTO drive shaft, it is critical to accurately measure the size. Improper size not only affects installation, but may also cause poor operation or even damage to agricultural equipment. Raydafon recommends that users remove the drive shaft from the equipment before measuring to ensure a more accurate and convenient measurement process.

The first thing to confirm is the total length of the drive shaft. This length refers to the distance from end to end of the PTO shaft in the retracted state, that is, from the outer edge of one fork to the outer edge of the other fork, excluding the protective cover. Many users tend to only measure the length of the sheath, which is inaccurate.

The second step is to measure the spline size, also known as the output end connector size. Common spline specifications include 1-3/8" 6 teeth, 1-3/8" 21 teeth, 1-3/4" 20 teeth, etc. When measuring, use a caliper to measure the outer diameter of the spline and count the number of spline teeth. Raydafon's PTO Shaft connector supports a variety of international standard specifications, which is convenient for docking with different agricultural machinery brands.

The third factor is the pipe diameter type and structure. The middle part of the PTO shaft is usually a hexagonal tube, star tube or square tube structure, which is an important factor in determining the torque capacity and telescopic range. You can use a vernier caliper to measure the distance between the opposite sides of the tube (such as parallel sides for hexagonal tubes and tooth spacing for star tubes), and record the total telescopic stroke.

The last inspection item is the safety protection structure. Although this is not part of the size, confirming whether the sleeve is complete and whether there are anti-slip rings at both ends of the shaft is also an important basis for determining whether a drive shaft can continue to be used.

If you are not sure how to measure, or are worried that the measurement error will affect the selection, you can also take a photo and record the measurement data and send it to Raydafon Technical team. We can provide you with dimension drawing confirmation, quick matching recommendation or custom processing services to ensure that you choose the right PTO Shaft and use it immediately after installation without modification. Feel free to contact us at any time to get a free dimension confirmation form or instruction video.

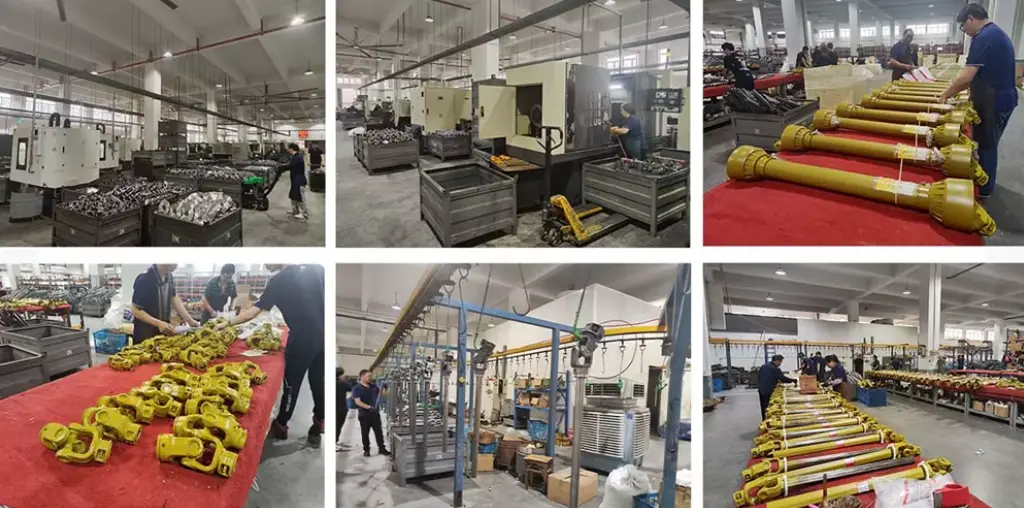

Raydafon is a manufacturer focusing on transmission and hydraulic technology, and has long served in the fields of agricultural equipment, industrial automation and new energy. The company is located in the core industrial belt of transmission parts in China. Relying on a complete supply chain system and independent processing capabilities, it has formed an integrated factory system from R&D, casting, finishing to assembly and testing. As a local powerful manufacturer, Raydafon always adheres to quality as the foundation, delivery as the criterion, and service as the support, and is committed to providing stable and reliable power transmission solutions for global customers.

Our product line covers multiple core categories, including high-efficiency worm gearboxes, compact and high-ratio planetary gearboxes, and hydraulic cylinders suitable for various agricultural machinery and engineering equipment. Whether it is standard parts or non-standard customization, Raydafon can respond quickly according to customer needs and provide flexible supporting solutions.

At present, Raydafon products have been widely used in sowing and fertilization machinery, mixing equipment, photovoltaic tracking systems, lifting platforms and other equipment, and exported to Southeast Asia, South America, Eastern Europe, the Middle East and other countries and regions, and are deeply recognized by users. We insist that each batch of products passes multiple rounds of factory inspections, including torque testing, sealing testing, assembly tolerance inspection, etc., to ensure that every product can "run stably and be delivered on time".

If you are looking for a reliable Chinese gearbox and hydraulic parts factory and supplier, Raydafon is a partner you cannot miss. We welcome global customers to come to discuss cooperation with drawings and samples, and are willing to help customers build efficient and durable mechanical systems with competitive prices, professional technology and continuous and stable delivery capabilities.