QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Want to purchase high-performance Agricultural Gearbox? Raydafon, as a professional manufacturer and factory in China, is your trusted supplier! Relying on China's complete agricultural machinery supporting industry chain, we not only realize the full process of independent manufacturing, but also control the price within a very competitive range, providing global agricultural machinery manufacturers, dealers and terminal farm customers with cost-effective, stable and reliable gearbox solutions.

Raydafon focuses on the research and development and manufacturing of agricultural gear transmission systems. Its main products cover lawn mower gearboxes, flail mower gearboxes (side-mounted grass shredder gearboxes), rotary tiller gearboxes, mower reducers, fertilizer and sowing machinery special gearboxes and other subdivided application fields. Each Agricultural Gearbox is structurally designed in combination with practical scenarios of agricultural machinery, with high transmission efficiency, low maintenance cost, strong adaptability, and suitable for all-weather farm conditions. All our gearboxes are produced in our own factories. From housing casting, gear processing, heat treatment to whole machine assembly and running-in test, we strictly follow the ISO 9001 quality management system to ensure that every product can withstand the test of high-intensity field operations.

Raydafon Agricultural Gearbox has the following major technical advantages:

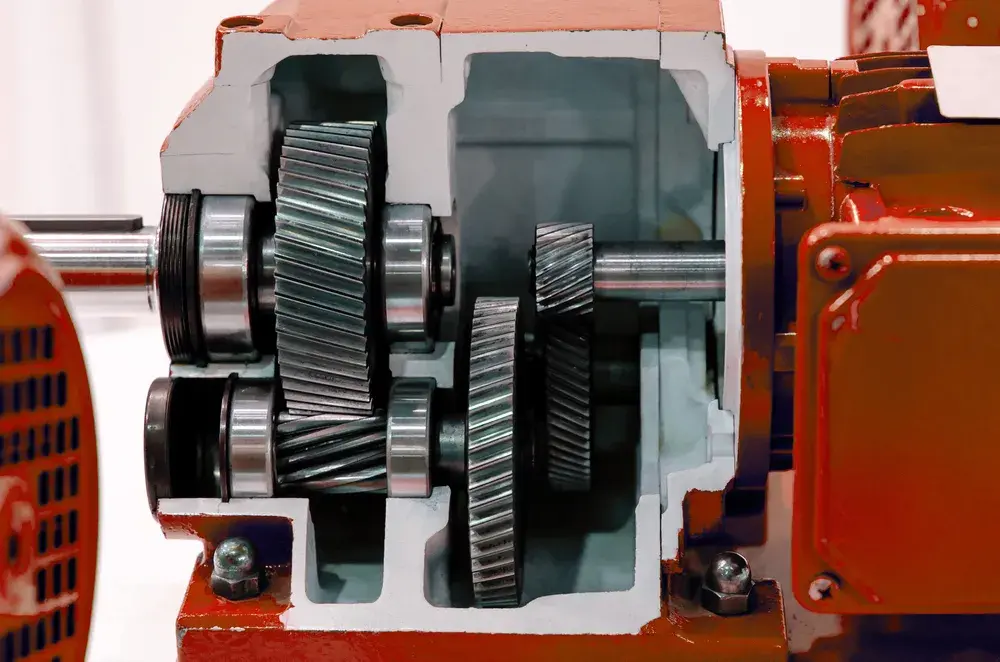

Compact structure and stable transmission: using high-quality alloy steel helical gears or spur gears for transmission, low running noise, small vibration, and improved mechanical life.

High torque output, adaptable to harsh working conditions: adopting large modulus design and high-hardness tooth surface treatment, it is suitable for heavy load, slippery, dusty environment, such as high grass dense forest, slope, gravel and other complex terrain operations.

A variety of optional installation interfaces: It can be matched with standard PTO input interface (1-3/8" Z6/Z21) and different output flange forms, and is compatible with a variety of agricultural machinery models.

Low maintenance design, long life operation: The internal lubrication system is optimized, equipped with oil level window and exhaust device, which greatly reduces the frequency of daily maintenance.

Customizable product support: We support OEM/ODM services, and can customize Agricultural Gearbox parameters according to customer drawings or usage requirements, including transmission ratio, installation direction, input/output form, housing structure, etc., and deliver samples in as fast as 15 days.

At present, Raydafon's products have been widely used in small and medium-sized tractors to mount agricultural implements, especially for high-standard farm machinery equipment in the European and American markets. Our products are sold well in Germany, Italy, the United States, Brazil and other developed countries in agricultural machinery, and are favored by many local brands and large agricultural machinery OEM manufacturers. We not only provide single-unit purchases, but also support large-volume customization and long-term supply agreements. We are your reliable partner in establishing a stable agricultural machinery supply chain.

In addition to Agricultural Gearbox, Raydafon has also been deeply involved in the field of precision gears, with Plastic gear, bevel A series of high-precision transmission parts such as gear and screw gear are widely used in industrial automation, food machinery, medical equipment and other industries, and can meet diversified supporting needs in one stop.

If you are looking for a cooperative manufacturer of Agricultural Gearbox with stable performance, reasonable price and quick response, Raydafon will be your reliable choice. Welcome to contact us to obtain the selection manual, technical parameter table and quotation plan. We will provide you with professional selection suggestions and fast delivery guarantee.

When choosing an agricultural gearbox, you should not only look at the price or appearance, but more importantly, match the actual application requirements to ensure that the equipment runs stably, has sufficient power, and has a long service life when working in the field. Here are a few key criteria for judgment:

1. Clarify the application type

Agricultural gearboxes have significant differences in design depending on the specific use. For example:

Gearboxes for lawn mowers require high-speed operation and impact resistance;

Gearboxes for tillers or rotary tillers emphasize torque output and structural strength;

Seeders and sprayers mostly use lightweight structures and have higher requirements for transmission efficiency and maintenance convenience.

First confirming which specific agricultural machinery the gearbox will be used for is the first step in the selection.

2. Matching parameters

The gearbox must be accurately matched with the power output interface of the host, and the following parameters need to be paid attention to:

Input speed and output speed ratio: different operations require different speed outputs;

Input/output shaft diameter and connection method: whether it is compatible with the PTO (power output shaft) interface;

Mounting hole spacing and installation direction: whether it is convenient to fix with agricultural machinery;

Rotation direction: avoid the equipment from failing to operate due to wrong direction.

3. Material and processing technology

High-quality agricultural gearboxes usually use ductile iron housings, and the internal gears are made of alloy steel such as 20CrMnTi. After carburizing and quenching, they are highly wear-resistant. If used in dusty or muddy environments for a long time, the sealing structure must be specially strengthened to prevent lubricating oil leakage.

4. Torque carrying capacity

Be sure to confirm whether the maximum output torque of the gearbox meets the requirements of agricultural machinery operations, especially when used in high-load scenarios such as turning over soil and cutting grass. At this time, heavy-duty gearboxes should be given priority.

5. Maintenance convenience

Agricultural equipment generally works continuously outdoors, and the convenience of maintaining the gearbox is also very important. The design with oil level observation window and oil drain port is more conducive to users' daily refueling and inspection.

The load-bearing capacity of the gearbox is a key factor in determining the stability and life of the equipment in the long-term high-load and high-intensity working environment of agricultural machinery. Raydafon has been deeply engaged in agricultural transmission systems for many years and has developed a series of high-performance gearbox products for different application scenarios, covering multiple series from light to heavy-duty.

Maximum torque range

The output torque of Raydafon agricultural gearbox covers:

Light series (such as sprayers, seeders): rated output torque 100~300 N·m;

Medium series (such as mowers, rotary tillers): rated output torque 500~900 N·m;

Heavy-duty series (such as balers, fertilizer mixers, crushers): can withstand a continuous output torque of up to 1500 N·m;

Special customized models: support peak torque of more than 2000 N·m, suitable for extreme working conditions and complex working environments.

Each gearbox is loaded and tested before leaving the factory to ensure that its load-bearing performance meets customer requirements.

Maximum speed range

The input speed of Raydafon gearbox is highly adaptable and generally supports the following speed range:

Standard input speed: 540 rpm and 1000 rpm, suitable for mainstream PTO output interface;

High-speed customized model: The input speed can support up to 2000 rpm, meeting the needs of some high-efficiency tractors and power machinery;

Output speed: According to different reduction ratios, the output range covers dozens to hundreds of rpm, which is determined by the model.

The gear adopts high-precision grinding technology and optimized tooth shape design to ensure smooth meshing at high speed, with a transmission efficiency of more than 96% and operating noise controlled below 72 dB.

In daily use, if the agricultural machinery gearbox is worn, leaks oil or the internal gear is abnormal, it is very important to disassemble and inspect and replace parts in time. The gearbox produced by our company has fully taken this practical demand into consideration during design. It has a compact structure but is easy to disassemble and assemble, and is maintenance-friendly.

Modular design, easy maintenance

The gearbox adopts a modular design, and the input shaft, output shaft, gear set and box body are assembled with standardized parts. Technicians only need conventional tools to complete most of the disassembly and assembly operations without professional equipment.

Simple shell structure and reasonable bolt arrangement

The box shell is a symmetrical split cast iron structure, and the bolt position is clear, unobstructed, and unstuck. During the disassembly process, you only need to loosen the bolts in sequence to open the box cover and conduct internal inspection.

High versatility of parts and easy replacement

Internal gears, oil seals, bearings and other components are highly versatile and standard in size. Replacement parts can be easily purchased according to the part number without customization, reducing maintenance costs.

Provide exploded diagram and disassembly and assembly instructions

Each Raydafon gearbox provides detailed exploded diagram and disassembly and assembly instructions, including part numbers, assembly sequence and precautions, which are convenient for customers to maintain by themselves and for remote guidance from the technical team.

It is recommended to check the oil seal and gear meshing surface regularly

We recommend that customers check the oil seal wear after every 500 hours of operation to ensure that the gearbox can operate stably for a long time, and observe whether there is abnormal wear or bite marks on the gear meshing surface. Timely treatment can effectively extend the service life.