QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

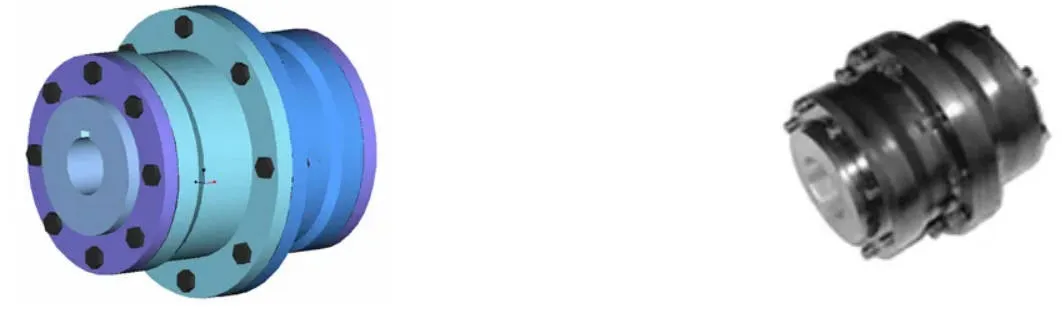

If your heavy machinery—steel mill rolling stands, cement plant crushers, mining conveyors—needs a coupling that won’t back down from high torque, Raydafon’s GIGL Drum Shape Gear Coupling is built for that exact job.

What makes it stand out? The drum-shaped teeth. They don’t just transfer power—they handle the mess of real-world use. Max torque hits 2000 kN·m, bore sizes go from 50mm to 400mm, and it can take up to 1.5 degrees of angular misalignment. On top of that, it compensates for axial and radial shifts that would wear out regular couplings fast. We make it from 42CrMo high-strength steel, then grind the involute gear teeth to precision—so power flows smooth, and wear stays low. No wonder it’s a staple for folks needing gear couplings for heavy machinery or high-torque gear couplings for industrial applications; it keeps running even when the machines are pushed hard.

This coupling isn’t just tough—it’s smart for maintenance too. It’s ISO 9001 certified, so you know the quality’s there. The gear mesh is lubricated, which cuts down on vibration and makes it last longer—even in dusty mines or sweltering cement plants. And it’s compact, so installing it on rolling mills or conveyor drives doesn’t turn into a big project. That’s why it’s top choice for durable drum gear couplings and custom gear couplings for mining equipment; we tweak sizes or surface treatments to fit exactly what your setup needs.

Raydafon’s factory is in China, so we balance good quality with prices that make sense. We don’t just sell a one-size-fits-all part—we work with you to get the right coupling for your machines. Less downtime, better efficiency, and a coupling that keeps your heavy equipment moving? That’s what we deliver.

The GIGL drum shape gear coupling stands out as a high-performance option in flexible gear coupling systems, tailor-made for tough industrial scenarios where reliable power transmission is non-negotiable. What makes this advanced drum shape gear coupling a top choice is its ability to handle angular misalignment effectively while keeping high torque transmission capabilities intact— a key demand for heavy-duty industrial setups. When compared to straight tooth gear couplings, the GIGL model takes the lead in load-bearing capacity: under the same inner sleeve outer diameter and maximum coupling outer diameter conditions, it delivers an average 15-20% boost in load tolerance, making it a go-to for high-load GIGL drum shape gear coupling applications.

One of its biggest advantages is enhanced angular displacement compensation— a critical factor for equipment where shafts might not stay perfectly aligned. When radial displacement is zero, straight tooth gear couplings can only handle an angular displacement of 1°, but the GIGL drum shape gear coupling steps up to allow up to 1°30'— that’s a 50% improvement. Even when modulus, tooth count, and tooth width are the same, the drum-shaped teeth of this coupling let it handle more angular displacement than straight teeth. This makes it ideal for low-speed, heavy-load environments that call for high torque gear coupling performance, such as in mining or metallurgy machinery where GIGL drum shape gear coupling’s misalignment tolerance is a game-changer.

The drum-shaped tooth surface of this flexible gear coupling also does wonders for improving contact between internal and external teeth. It fixes common issues with straight tooth couplings, like edge squeezing and stress concentration at tooth ends when there’s angular displacement. At the same time, it cuts down on friction and wear, lowers noise levels, and extends maintenance intervals— saving businesses time and money on upkeep. Another practical plus is the flared shape of the outer tooth sleeve: it makes assembling and disassembling the internal and external teeth much easier, which boosts day-to-day operational efficiency for teams working with GIGL drum shape gear coupling installations.

When it comes to transmission efficiency, the GIGL drum shape gear coupling hits an impressive 99.7%— a number that speaks to its reliability for industrial gear coupling uses, from conveyor systems in manufacturing to heavy machinery in construction. Thanks to these strong attributes, drum shape gear couplings like the GIGL have largely replaced straight tooth versions around the world, especially in applications where durable GIGL drum shape gear coupling performance is a must. The outer tooth sleeve uses drum-shaped teeth for smooth meshing, and it’s made from high-quality steel with medium-hard tooth surfaces to support heavy loads. If customers need even more performance, we can provide tooth surface hardening (with HRC ≥ 56) to upgrade its durability. Plus, the coupling has a lightweight design that keeps rotational inertia low— perfect for equipment where speed and precision matter.

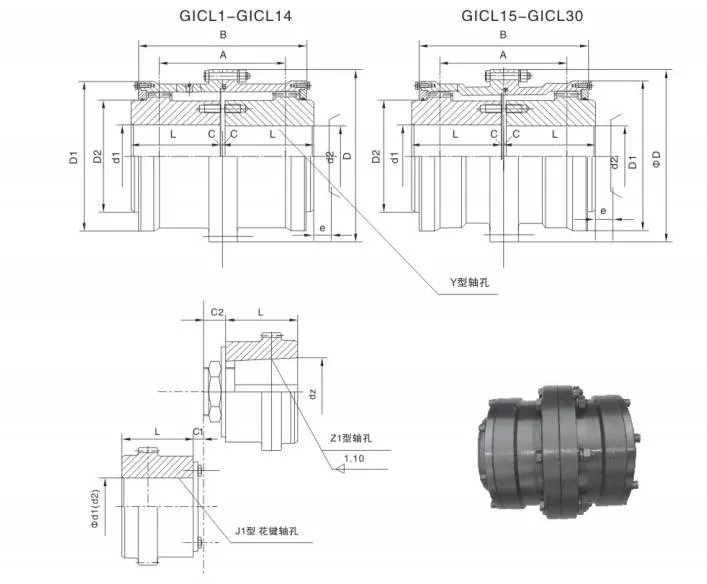

To keep the GIGL drum shape gear coupling running well long-term, it’s equipped with reliable lubrication structures and seals that extend its service life and make maintenance simple. Its symmetrical design ensures excellent interchangeability, so replacing parts is straightforward if needed. For high-speed operations where peripheral speeds go over 36 m/s, we apply dynamic balancing to prevent vibration and ensure stable performance. The shaft hole configurations also offer flexibility: combining Y, Z1, and J1 types to fit different connection needs for various industrial machines that use GIGL drum shape gear coupling. Raydafon, a trusted manufacturer, produces a full range of drum shape gear couplings beyond GIGL, including GICL, GIICL, GICLZ, GIICLZ, and NGCL variants— all meeting strict industry standards to guarantee quality.

This rigid-flexible coupling packs in plenty of benefits: compact structure, small turning radius, high load capacity, top-tier efficiency, low noise, and long maintenance cycles. It’s especially well-suited for low-speed, heavy-duty conditions in industries like metallurgy (for rolling mills), mining (for crushers), lifting and transportation (for cranes), as well as petroleum, chemical, and general machinery shaft transmissions— all areas where GIGL drum shape gear coupling’s robustness shines. That said, it’s important to note: because of its high rigidity and flexibility without elasticity, it’s not recommended for machinery that needs vibration damping, buffering, or extremely strict shaft alignment— such as precision equipment where even small vibrations could affect performance.

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Tel

+86-574-87168065

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Copyright © Raydafon Technology Group Co.,Limited All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |