QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

If your heavy machinery—think construction gear that hauls loads all day or agricultural harvesters that work nonstop through planting season—needs a coupling that fits tight spaces but still delivers big torque, Raydafon’s SWP-G Super Short Flex Type Universal Joint Coupling is exactly what you’re looking for. It’s built specifically for those compact setups where every inch counts, without skimping on the power you need.

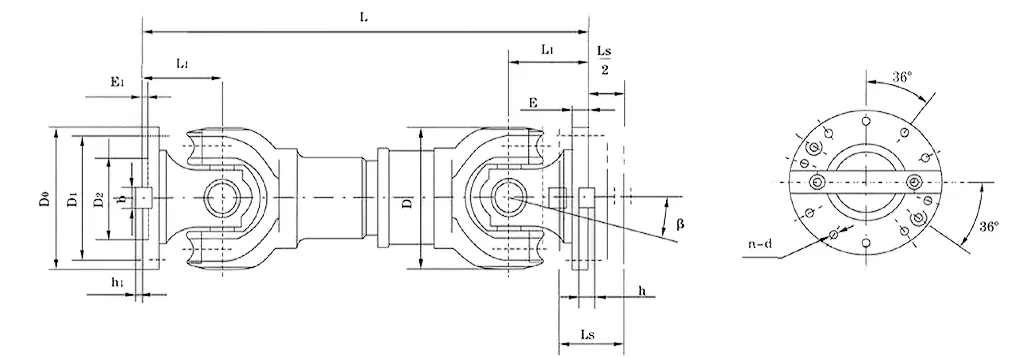

First, let’s talk about its size: that “super short” design isn’t just a label—it’s made to squeeze into tight spots other couplings can’t reach, which is a lifesaver when your machinery’s components are packed close together. Its gyration diameters range from 225mm to 350mm, so it fits right into mid-sized heavy equipment setups. As a short flex universal joint coupling, it handles up to 5 degrees of angular misalignment—enough to account for the small shifts that happen when machinery’s running hard—while carrying torque up to 224 kN·m. And it has a flexible element built in, which soaks up shocks and vibrations so your other parts don’t take the brunt of the wear.

We didn’t cut corners on materials, either. It’s made with high-strength steel for durability and bronze components that add smoothness to its movement—so it holds up to the rough-and-tumble of construction sites or the dust and debris of farm fields. That’s why it’s a top pick for universal joint couplings for heavy machinery; it doesn’t just work once—it keeps going, even when conditions get messy. For farmers, it’s also a reliable flexible coupling for agricultural equipment, tough enough to handle harvest season’s long hours without breaking down.

At Raydafon, our manufacturing in China sticks strictly to ISO 9001 standards—every SWP-G coupling gets checked for quality, from the steel we use to the flexible element’s fit. We know no two jobs are the same, so we offer tailored solutions too—whether you need a slight tweak to the size or a specific adjustment for your equipment. And best of all, it’s priced competitively—you get a durable universal joint coupling that fits your space and your budget. For anyone tired of couplings that are too big, too weak, or too expensive, this SWP-G model is the no-fuss, high-performance solution you’ve been looking for.

| Model | SWP225G | SWP250G | SWP285G | SWP315G | SWP350G | |

| D | 225 | 250 | 285 | 315 | 350 | |

| Tn KN.m | 56 | 80 | 112 | 160 | 224 | |

| Tf KN.m | 28 | 40 | 56 | 80 | 112 | |

| β≤ | 5° | 5° | 5° | 5° | 5° | |

| Size(mm) | S | 40 | 40 | 40 | 40 | 50 |

| L | 470 | 600 | 665 | 740 | 850 | |

| D | 275 | 305 | 348 | 360 | 405 | |

| D1 | 248 | 275 | 314 | 328 | 370 | |

| D2(H7) | 135 | 150 | 170 | 185 | 210 | |

| E | 15 | 15 | 18 | 18 | 22 | |

| E1 | 5 | 5 | 7 | 7 | 8 | |

| b-h | 32-18 | 40-18 | 40-24 | 40-24 | 50-32 | |

| h1 | 9 | 9 | 12 | 12 | 16 | |

| L1 | 80 | 100 | 120 | 135 | 150 | |

| n-d | 10-15 | 10-17 | 10-19 | 10-19 | 10-21 | |

| M(kg) | 78 | 142 | 190 | 260 | 355 | |

* Note: marking examples: gyration diameter D=315mm, installment length L=620mm, G type-Short without flex type SWP315GX620 coupling

Raydafon’s SWP-G Super Short Flex Type Universal Joint Coupling is built for those tight spots where you need both flexibility and power. It’s made to move torque efficiently in spaces that don’t have room for bulky parts, even when shafts aren’t perfectly aligned. This isn’t just any coupling—it’s a high-torque universal joint coupling that shines when you need a short length but refuse to skimp on performance, even under heavy loads.

Take construction equipment and heavy machinery, for example. Excavators digging into tough soil, loaders moving tons of material—they all have tight spaces where parts rub close together. The SWP-G fits right in as a reliable universal joint coupling for industrial machinery, soaking up vibrations and handling the constant movement these machines deal with. Its super short design slips into cramped assemblies without a fuss, making sure power gets where it needs to go without sacrificing durability or how well it works.

Farmers will appreciate it too. Tractors plowing uneven fields, harvesters working through rough terrain—they need couplings that can keep up with the bumpy rides and changing speeds. This SWP-G acts as a sturdy universal joint coupling for drive shafts in agricultural gear, adjusting to the angular misalignments that come with off-road work. That means less wear on the machinery, so it lasts longer even when field conditions get rough.

Marine setups love it too, especially in tight engine compartments on boats. Saltwater and moisture don’t stand a chance against its corrosion-resistant build, making it a top pick as a marine universal joint coupling. It handles the dynamic loads from waves and the push of propulsion systems, keeping things running smoothly whether you’re out at sea or in a busy harbor.

And let’s not forget renewable energy—wind turbines spinning high up, solar trackers moving with the sun. These systems need precise control in limited spaces, and the SWP-G steps up as a versatile universal joint coupling for renewable energy equipment. It manages high torque without much backlash, so you get reliable performance with little need for maintenance—perfect for keeping sustainable energy systems running strong.

At Raydafon, we don’t just sell the SWP-G—we tailor it to your needs. Whether you’re working on construction gear, farm machinery, boats, or renewable energy setups, we can adjust it to fit exactly what you’re building. If you want to see how this coupling can make your operations smoother, just reach out to our team. We’ll show you why it’s the smart choice for tight spaces and tough jobs.

Raydafon’s SWP-G Super Short Flex Type Universal Joint Coupling stands out first for its compact build—this thing’s designed to squeeze into tight mechanical setups where space is at a premium, but it never skimps on flexibility or torque. If you’re dealing with high-torque jobs, it’s a top-tier high-torque universal joint coupling: it has advanced flex elements that let it handle pretty big angular misalignments without messing up performance, which is a game-changer for dynamic environments where shafts shift as machinery runs.

Durability is another big win here. We use tough, high-strength materials and build every part with precision, so it resists wear and fatigue even when it’s running nonstop. That makes it a solid universal joint coupling for industrial machinery—think pumps that run all day or compressors under constant load. It soaks up shocks and vibrations, keeping power transmission steady so your equipment doesn’t take unnecessary strain.

Its super short length is a lifesaver for drive systems too. When you’re working on automotive or transportation setups, every inch matters—and this coupling fits right in as an efficient universal joint coupling for drive shafts. It uses bolted or keyed connections, so attaching it is fast, and it cuts down on maintenance time later. Plus, it handles axial movements well, so you don’t have to worry about it slipping or misfitting as parts shift during use.

Corrosion resistance? It’s got that covered. We add protective coatings that stand up to harsh stuff—like saltwater in marine setups. That’s why it works great as a marine universal joint coupling for propulsion systems: it can handle the salt spray and variable loads out at sea without rusting or breaking down, keeping boats running smooth.

And if you’re focused on eco-friendly setups, this coupling delivers there too. It transfers energy precisely with barely any backlash, so it doesn’t waste power. That makes it a reliable universal joint coupling for renewable energy equipment—perfect for wind turbines spinning in the wind or solar trackers moving with the sun. It keeps those sustainable systems running efficiently, which is exactly what you need for green energy projects.

At Raydafon, we make sure every SWP-G meets strict quality standards, and we can tweak it to fit your specific needs—whether you need a different coating, a slightly adjusted length, or a custom connection. If you want to know more about its specs or how to integrate it into your setup, just talk to our specialists. We’ll help you get exactly what your machinery requires.

⭐⭐⭐⭐⭐ Li Jian, Senior Engineer, Shanghai Industrial Equipment Co., Ltd.

We’ve had Raydafon’s SWP-G Super Short Flex Type Universal Joint Coupling on our production line for a few months now, and it’s honestly outperformed what we hoped for. Our machines have always been tight on space—every inch matters—and this coupling’s compact design fits like it was made just for them, no more squeezing parts to make room. But it doesn’t skimp on function, either: even when there’s a little misalignment (which is inevitable with heavy use), its flexibility keeps power transmission smooth, no jolts or hiccups.

It’s tough, too—handles high-torque tasks without breaking a sweat, and after months of running, we’ve barely seen any wear. Installation was a quick job, too; our team had it set up in no time, and it’s been reliable ever since. For anyone with space-constrained gear that still needs heavy-duty performance, this coupling’s a no-brainer.

⭐⭐⭐⭐⭐ Emily Walker, Technical Director, New York Manufacturing Solutions, USA

We swapped out our old, bulky couplings for Raydafon’s SWP-G at our New York facility, and the difference was obvious from day one. Those old units took up way too much space and always felt clunky—but this one fits right into the tight spots, and the power transfer? Smooth and steady, even when we’re pushing the machines to handle high loads.

The biggest win, though, is the downtime. We used to stop production every few weeks to tweak or fix the old couplings, but with this one? Hardly any. Maintenance costs have dropped, too—no more frequent part replacements or emergency repairs. And when we had a question about installation, Raydafon’s customer service got back to us fast with clear answers. We’re already planning to use their products for our next upgrade; they’ve earned our trust.

⭐⭐⭐⭐⭐ Andrea Rossi, Operations Manager, Milan Engineering, Italy

Adding Raydafon’s SWP-G coupling to our Milan machinery was one of the best calls we’ve made for our high-precision work. In our line of work, space and alignment are make-or-break—if a part is too big or can’t handle small misalignments, it throws off the whole process. This coupling checks both boxes: its small size fits our tight setups, and the flexible design keeps operations smooth, no matter the minor adjustments we need.

Since we installed it, we’ve had way fewer maintenance headaches—no more stopping production to fix alignment issues or replace worn parts. And when we run it at high speeds (which we do daily), it holds up perfectly. Durability-wise, it’s exceeded what we expected, too—after months of heavy use, it still looks and performs like new. If you need a high-quality coupling for precision work, Raydafon’s the way to go.

⭐⭐⭐⭐⭐ Jean-Claude Lefevre, Maintenance Supervisor, Lyon Mechanical Works, France

We’ve been running Raydafon’s SWP-G coupling in our machines for over six months now, and it’s been a game-changer for our team. First off, the compact design—our equipment has such tight spaces, and this coupling slides right in without needing us to rearrange other parts. Then there’s the flexibility: it takes the stress off our machines, which means less wear on other components and fewer breakdowns.

Even when we’re running heavy loads, its performance stays consistent—no dips, no weird noises, just reliable operation. Installation was simple, too; our techs didn’t need to spend hours figuring it out. The best part? Our production line efficiency is way up now, thanks to less downtime. We’ll absolutely keep using Raydafon’s products—this coupling has proven it’s worth it.

Raydafon’s SWP-G Super Short Flex Type Universal Joint Coupling works by using flexible torque transmission—think of it as a bridge between shafts that can move a little without breaking the connection. It uses elastomeric elements (fancy for flexible, rubber-like parts) to handle misalignments, all while making sure power gets from one shaft to the other without wasting energy. As a compact high-torque universal joint coupling, it’s got a central flexible disc or spider that soaks up angular, axial, and radial shifts—so even when shafts aren’t perfectly lined up, rotation stays smooth, even in those tight spaces where every inch counts.

The heart of how it works is in its super short design. It combines tough, flexible components that can bend a little under load to make up for offsets, which keeps too much stress from hitting your machinery. That’s why it’s such a solid universal joint coupling for industrial machinery—whether speeds or loads change, it passes rotational force along with barely any backlash, so your equipment stays stable.

Here’s the breakdown: the input shaft spins, which moves the flexible element, and that element then carries the torque over to the output shaft by flexing just enough—no jerks, no sudden stops. This is a big deal for drive shafts, making it a reliable universal joint coupling for drive shafts in setups like automotive drivetrains, where you need precise alignment but don’t have a lot of room to work with.

When things get rough—like in marine environments with waves tossing the boat around—the SWP-G’s flex design soaks up vibrations and shocks, which helps it last longer. It’s a tough marine universal joint coupling because those flexible parts resist corrosion and handle the back-and-forth motion from waves, keeping propulsion efficient no matter how choppy the water gets.

And for green energy setups? This principle shines there too. It moves energy efficiently, with hardly any loss, making it a great universal joint coupling for renewable energy equipment. Whether it’s in compact solar trackers or small wind turbines, it keeps things running smoothly without wasting power—perfect for sustainable systems where every bit of efficiency counts.

At Raydafon, we build the SWP-G to be reliable and ready to fit your specific needs. If you want the technical details or need help figuring out how it fits into your setup, our specialists are here to walk you through it—no jargon, just straight answers.

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Tel

+86-574-87168065

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Copyright © Raydafon Technology Group Co.,Limited All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |