QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

If you’re dealing with machinery like pumps that move fluids all day, fans that keep spaces ventilated, or textile equipment that runs nonstop—you need a coupling that’s flexible enough to handle small misalignments but tough enough to keep torque moving steady. That’s exactly what Raydafon’s NL Type Nylon Gear Flexible Coupling is built for. It handles up to 4mm of axial misalignment and 2 degrees of angular misalignment, so even when your shafts aren’t perfectly lined up, it keeps your gear running without a hitch.

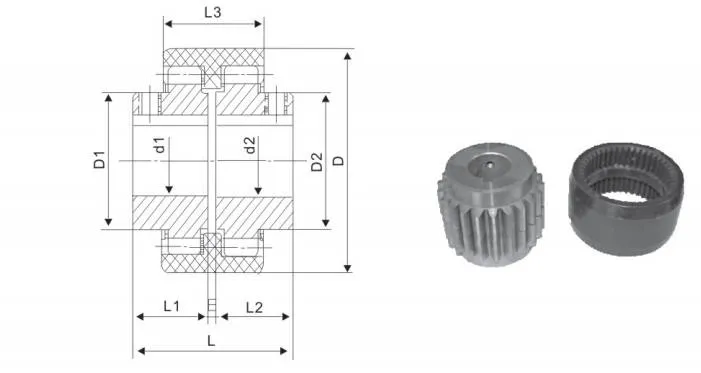

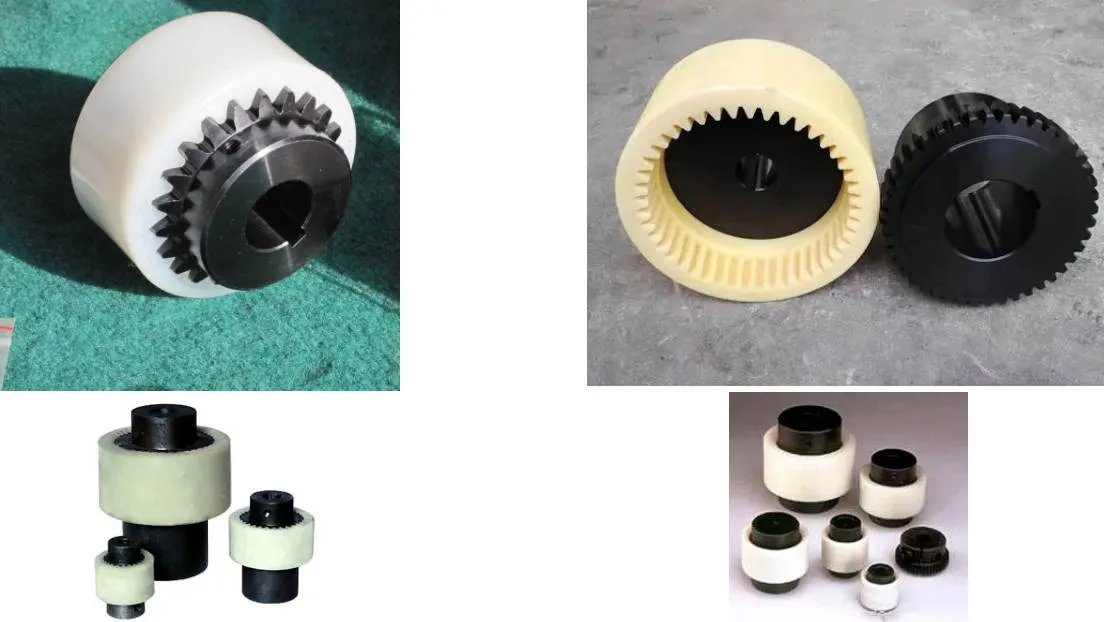

We’ve got models from NL1 all the way to NL10, so there’s a fit for almost any light to medium-duty job. Torque capacities range from 40 N·m to 3150 N·m, and bore diameters go from 6mm to 100mm—no need to hunt for a size that’s too big or too small. What makes this nylon gear flexible coupling stand out is its build: a high-strength nylon sleeve paired with steel hubs. That combo means it runs quiet, and you barely have to touch it for maintenance—no constant checks or fixes to slow you down. It’s a go-to for flexible gear couplings for industrial machinery, and if you’re specifically working with pumps, it’s one of the most reliable nylon sleeve gear couplings for pumps around. Plus, its compact design fits into tight setups, and it works smoothly between -20°C and +70°C—no matter if your workspace is chilly or warm.

At Raydafon, we make these couplings in China, and we stick strictly to ISO 9001 standards—every part gets checked to make sure it’s durable and ready to last. The nylon sleeve isn’t just strong, it’s non-conductive and corrosion-resistant too. That’s a game-changer for humid spaces or areas with chemicals, where other couplings might rust or short out—this one keeps going longer. And its simple structure makes assembly and disassembly a breeze: no complicated tools, just quick work when you need to swap it out or do maintenance. That’s why it’s a top pick for custom nylon gear couplings—we can tweak it to fit your specific setup—and it’s one of the most durable flexible gear couplings for textile equipment, holding up to the constant motion of weaving or spinning machines.

We offer all kinds of sizes and shaft configurations, so you get a coupling that’s tailored to your machinery—not a one-size-fits-none option. And we keep the price competitive, so you don’t have to overspend for quality. For businesses worldwide, this means less downtime (since it’s easy to install and maintain) and better equipment efficiency—exactly what you need to keep operations running smooth.

The core working logic of the NL type nylon gear flexible coupling relies on the meshing gear teeth to achieve torque transmission, while the nylon sleeve inside, as a key flexible component, can not only effectively compensate for shaft system misalignment but also play an important role in absorbing shocks. In this structural design, two hubs with external teeth are connected through a built-in nylon internal gear sleeve. This combination not only ensures efficient power transmission in mechanical systems but also significantly reduces vibrations and impacts generated during operation. This design advantage is particularly evident in application cases of NL type nylon gear flexible couplings that need to be adapted to small and medium-sized equipment.

When the driving shaft transmits torque to one of the hubs, the external teeth on the hub will accurately mesh with the internal teeth of the nylon internal gear sleeve, and then the nylon internal gear sleeve will smoothly transmit power to the other hub connected to the driven shaft. Even under working conditions where there is angular, parallel or axial misalignment in the shaft system, this meshing transmission mechanism can still ensure the stable operation of the equipment. Therefore, in fields that require reliable flexible gear coupling solutions, such as the transmission systems of automated production lines, the power connection of pump equipment and the driving devices of conveyors, the NL type nylon gear flexible coupling is a preferred product.

The nylon material used in the NL type nylon gear flexible coupling itself has excellent elasticity and damping properties, which can not only reduce the wear of the mechanical equipment connected to it but also extend the service life of the entire transmission system. As a professional gear coupling manufacturer, Raydafon selects advanced materials and optimizes the manufacturing process when producing NL type couplings, enabling the products to maintain excellent performance under complex working conditions in different industries. For example, in scenarios dealing with variable loads, the NL type nylon gear flexible coupling produced by Raydafon can rely on its excellent misalignment compensation capability to avoid transmission failures caused by shaft system misalignment and reduce equipment downtime.

In order to keep the NL type nylon gear flexible coupling maintaining stable working efficiency, daily maintenance is essential, among which regular lubrication of the gear tooth parts is a key link. Reasonable lubrication can reduce friction loss during gear tooth meshing, further improve the operation stability of the coupling and reduce the probability of failures. In general, the working principle of the NL type nylon gear flexible coupling is to achieve strong torque transmission while taking into account the flexibility and stability of the transmission system through the synergistic effect of the rigid hub and the flexible nylon sleeve. As an experienced gear coupling supplier, Raydafon always controls product precision and reliability in strict standards to ensure providing customers in various industries with NL type nylon gear flexible coupling products with strong adaptability and high durability.

The NL Type Nylon Gear Flexible Coupling is specifically engineered for high-performance applications in demanding mechanical scenarios. It ensures stable power transmission while flexibly accommodating shaft misalignments, making it a highly competitive option in the category of nylon sleeve gear couplings. A key design highlight of this coupling lies in its high-strength nylon sleeve, which not only endows the coupling with excellent elastic deformation capability but also significantly enhances the durability of the overall structure. This makes it particularly suitable as a critical flexible nylon sleeve gear coupling component in industrial equipment that operates for extended periods.

In terms of torque transmission capacity, the NL Type Nylon Gear Flexible Coupling delivers outstanding performance, easily handling high-torque load requirements. Whether in heavy-duty machine tools, mining machinery, or large-scale conveyor equipment—all of which demand high reliability in power transmission—it operates stably, establishing itself as a preferred high-torque nylon gear coupling model for numerous high-torque working conditions. When addressing the common issue of shaft misalignment during mechanical operation, this flexible nylon gear coupling also demonstrates excellent adaptability. It can effectively absorb and compensate for angular misalignment, parallel misalignment, and axial misalignment, thereby significantly reducing the additional stress on connected shafts and helping to extend the service life of the entire transmission system. This feature is especially crucial for production equipment that requires long-term continuous operation.

Furthermore, the nylon material of the NL Type Nylon Gear Flexible Coupling inherently possesses excellent shock absorption and buffering properties. During equipment operation, it can effectively reduce the impact of vibrations and shocks, ensuring smoother operation of the transmission system. Consequently, in dynamic working conditions with frequent vibrations, it has become the preferred shock-absorbing nylon gear coupling solution for many enterprises. In terms of corrosion resistance, in addition to the nylon sleeve's excellent chemical corrosion resistance, the metal components of this coupling undergo special treatment, enabling stable operation in humid, dusty, or slightly corrosive environments. Compared to traditional rigid couplings, it exhibits stronger adaptability in harsh working conditions, fully meeting the industrial sector's requirements for durable nylon gear couplings.

From the perspective of operation and maintenance, the NL Type Nylon Gear Flexible Coupling adopts a maintenance-free design. It eliminates the need for frequent lubricant addition or adjustments, which not only reduces the workload of daily maintenance but also lowers the risk of equipment failures caused by improper maintenance. This effectively controls operational costs and downtime, perfectly aligning with the selection criteria of industries pursuing efficient and low-consumption production for low-maintenance flexible gear couplings. Meanwhile, its overall structure is lightweight and compact, facilitating simple and quick installation and disassembly. Even in equipment layouts with limited space, the assembly of this compact nylon gear coupling can be easily completed, further improving the efficiency of equipment installation and maintenance.

In summary, integrating the NL Type Nylon Gear Flexible Coupling into a transmission system provides more stable and efficient operational support for equipment. Particularly in the precision manufacturing field, where high-precision transmission is required, this high-performance nylon sleeve gear coupling—with its optimized design—fully meets the multiple demands for transmission accuracy, reliability, and adaptability, serving as a vital component in enhancing the overall performance of equipment.

The NL Type Nylon Gear Flexible Coupling works as a go-to transmission part for all sorts of mechanical setups that need steady power transfer. What makes it stand out is the nylon sleeve—it bends just right to soak up vibrations and fix small shaft misalignments, so it’s perfect for any gear coupling use where you need reliable torque movement without parts wearing out too fast.

Take industrial machinery, for example. This coupling is great for hooking up motors to pumps or compressors. When those machines run, they often send sudden shock loads through the system, but the NL Type Nylon Gear Flexible Coupling eases that impact, helping the whole setup last longer. And on conveyor lines—you know, the ones that move materials nonstop in factories—this industrial nylon sleeve gear coupling keeps things running smooth even when the load changes. Unlike old rigid couplings that break down often, this one cuts down on downtime and the money you spend fixing things.

The automotive and transportation world uses it too, especially for drive shafts and steering parts. Cars and trucks have to deal with a lot of twisting vibrations when they move, but this flexible gear coupling for automotive drives soaks those up. That not only makes the vehicle run better but also safer—no weird shakes throwing off the steering or wearing down the drive train.

When it comes to precision gear coupling uses, like CNC machines or industrial robots, this coupling really shines. Those machines spin fast and need super accurate movement, but even small shaft misalignments (like angles or parallel shifts) can mess things up. The NL Type Nylon Gear Flexible Coupling fixes those issues while keeping up with high speeds. That’s why so many companies building automated assembly lines look for this nylon gear coupling for precision CNC equipment when they need custom setups.

You’ll also find it in HVAC systems and water treatment plants. Those places use fans and blowers a lot, and if those parts vibrate too much, they get loud and break down. This vibration-damping flexible gear coupling for HVAC fans keeps the noise down and the equipment running steady—no unexpected stops in heating/cooling or water treatment processes.

All in all, the NL Type Nylon Gear Flexible Coupling is a budget-friendly pick for almost any industry. It’s tough, easy to install, and gets the job done. If you’re looking for a reliable industrial gear coupling supplier, Raydafon can hook you up with custom options that fit your exact needs—so you get the best performance and a long-lasting part.

⭐⭐⭐⭐⭐ Wang Lei, Mechanical Engineer, Guangzhou Machinery Co., Ltd.

We’ve had Raydafon’s NL Type Nylon Gear Flexible Coupling on our assembly lines for a while now, and it’s been a steady performer—way more reliable than some of the other couplings we’ve tried. The nylon gear design is the standout here: it moves torque smoothly, no jerky transfers, and it cuts down on vibration so much that you can actually tell the difference in how the machines run.

Installation was a total breeze, too. We don’t have a lot of extra space in our equipment, but this coupling fit perfectly right out of the box—no need to modify anything. It’s been running nonstop, and there’s barely any sign of wear; that durability means we’re not stopping production to fix or replace it as often. All in all, it’s a solid, cost-effective pick that does exactly what we need it to.

⭐⭐⭐⭐⭐ John Smith, Plant Manager, Chicago Industrial Solutions, USA

We swapped out our old metal coupling for Raydafon’s NL Type Nylon Gear one at our Chicago facility, and the change was night and day—you could feel it the second we fired up the machines. The vibration that used to rattle parts loose? Gone. The loud hum from the old coupling? Quieted down so much the floor feels calmer. And power transfer? Smooth as can be, even when we’re running heavy loads.

What’s more, it handles misalignment way better than the metal one ever did—no more tweaking it every week to keep things on track. Raydafon got it to us fast, too; delivery was right on schedule, and the quality’s top-notch—no cheap parts or shoddy work. I’ve already told a few other plant managers about it; this is the kind of product you want to pass the word on about.

⭐⭐⭐⭐⭐ Anna Müller, Maintenance Supervisor, Munich Engineering, Germany

We put Raydafon’s NL Type coupling in our high-speed machinery a few months back, and it’s been a game-changer for our team. The nylon gear material is a smart call— it doesn’t wear down as fast as metal, so we’re not replacing parts as often, and it’s way quieter. That might sound small, but a quieter shop means less fatigue for the team, and fewer distractions when we’re checking equipment.

It’s flexible enough to handle the slight shifts that come with high-speed running, but still strong enough to hold up under pressure—no bending or breaking. Installation was simple, too; our techs had it set up in an hour, no complicated instructions. We’ve had way fewer machine stoppages since we installed it, and everything runs smoother. Raydafon’s proven they’re a supplier we can count on—no surprises, just good products.

⭐⭐⭐⭐⭐ Carlos Martínez, Operations Director, Madrid Manufacturing Corp., Spain

Raydafon’s NL Type Nylon Gear Flexible Coupling is exactly the high-quality product we were looking for. We added it to our production line hoping to cut down on vibration and boost efficiency—and it delivered on both counts, no questions asked. The nylon gear gives it just the right amount of flexibility to keep things running smooth, but it doesn’t sacrifice strength—even when we’re pushing the line to meet tight deadlines.

It’s compact, too, which is a big plus for our setup; we don’t have a lot of extra space, and this coupling fits right in without crowding other parts. We’ve been using it for months now, and there haven’t been any issues—no breakdowns, no weird noises, just consistent performance. Between the product itself and the great service we got from Raydafon, we’re more than satisfied. This one’s a keeper.

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Tel

+86-574-87168065

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Copyright © Raydafon Technology Group Co.,Limited All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |