QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Raydafon’s GICLZ drum gear coupling is purpose-built for high-torque power transfer in heavy industrial machinery—think steel mills, cement plants, and mining equipment. It’s the go-to core transmission part for handling tough, unforgiving work environments. What sets it apart? A drum-shaped tooth design, with those teeth crafted from high-strength 42CrMo steel. This build lets it handle up to 2000 kN·m of torque, fit bore diameters ranging from 50 mm to 400 mm, and even cope with angular misalignments up to 1.5 degrees—all while keeping backlash ultra-low for smooth, steady power flow.

For heavy machinery operations, this high-torque drum gear coupling cuts down on component wear big time. It’s perfect as a drum gear coupling made just for heavy machinery and a top pick for drum gear couplings that fit industrial equipment like a glove. Raydafon’s tight manufacturing tolerances mean this coupling holds up in rough industrial settings—less vibration messing with equipment performance, and way fewer trips for maintenance (which saves time and money, too).

Here’s another win: the GICLZ drum gear coupling is ISO 9001 certified. Its gear teeth get lubrication right where they mesh, and the whole unit is built tough—so it lasts longer even when dust is thick or temperatures swing to extremes. Installation’s a breeze, too, thanks to its compact welded design—ideal for rolling mills, conveyor systems, and similar setups. No wonder it’s a standout long-lasting drum gear coupling and a favorite for custom drum gear couplings tailored to mining equipment.

Based in China, Raydafon offers all sorts of custom tweaks for businesses worldwide. Need a specific size? Done. Want carburizing (or another surface treatment) for extra durability? No problem. And all this comes at prices that compete—without cutting corners on quality. Add this coupling to your setup, and you’ll get longer equipment life and better overall efficiency. For heavy industrial companies looking to upgrade their transmission systems, it’s a solid, dependable choice.

| 类型 Type | 许用扭矩 Limited torque KN·m | 转速 Limited rotational speed R/min | 轴孔直径 Diameter of the shaft hole d1, d2 | 轴孔长度 Length of the shaft hole L | D mm | D1 mm | D2 mm | D3 mm | B1 mm | C mm | 转动惯量 Rotate the inertia Kg·m² | 重量 Weight Kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| GICLZ1 | 0.800 | 7100 | 16.18.19 | 42 | 125 | 95 | 60 | 80 | 57 | 24 | 0.0084 | 5.4 |

| 20.22.24 | 52 | 14 | ||||||||||

| 25.28 | 62 | 16 | ||||||||||

| 30.32.35.38 | 82 | 6.5 | ||||||||||

| 40.42.45.48.50 | 112 | 6.5 | ||||||||||

| GICLZ2 | 1.400 | 6300 | 25.28 | 62 | 145 | 120 | 75 | 95 | 67 | 16 | 0.018 | 9.2 |

| 30.32.35.38 | 82 | 8 | ||||||||||

| 40.42.45.48.50.55.56 | 112 | 7 | ||||||||||

| 60 | 142 | 8 | ||||||||||

| GICLZ3 | 2.800 | 5900 | 30.32.35.38 | 82 | 170 | 140 | 95 | 115 | 77 | 19 | 0.0427 | 16.4 |

| 40.42.45.48.50.55.56 | 112 | 7 | ||||||||||

| 60.63.65.70 | 142 | 7 | ||||||||||

| GICLZ4 | 5.000 | 5400 | 32.35.38 | 82 | 195 | 165 | 115 | 130 | 89 | 8.5 | 0.076 | 22.7 |

| 40.42.45.48.50.55.56 | 112 | 9.5 | ||||||||||

| 60.63.65.70.71.75 | 142 | 9.5 | ||||||||||

| 80 | 172 | 11.5 | ||||||||||

| GICLZ5 | 8.000 | 5000 | 40.42.45.48.50.55.56 | 112 | 225 | 183 | 130 | 150 | 99 | 9.5 | 0.0149 | 36.2 |

| 60.63.65.70.71.75 | 142 | 9.5 | ||||||||||

| 80.85.90 | 172 | 11.5 | ||||||||||

| GICLZ6 | 11.200 | 4800 | 48.50.55.56 | 112 | 240 | 200 | 145 | 170 | 109 | 11.5 | 0.24 | 46.2 |

| 60.63.65.70.71.75 | 142 | 9.5 | ||||||||||

| 80.85.90.95 | 172 | 9.5 | ||||||||||

| 100 | 212 | 11.5 | ||||||||||

| GICLZ7 | 15.0 | 4500 | 60.63.65.70.71.75 | 142 | 260 | 230 | 160 | 185 | 122 | 10.5 | 0.43 | 68.4 |

| 80.85.90.95 | 172 | 10.5 | ||||||||||

| 100.110.120 | 212 | 10.5 | ||||||||||

| GICLZ8 | 21.2 | 4000 | 65.70.71.75 | 142 | 280 | 245 | 175 | 210 | 132 | 12 | 0.61 | 81.1 |

| 80.85.90.95 | 172 | 12 | ||||||||||

| 100.110.120 | 212 | 12 | ||||||||||

| 130 | 252 | 12 | ||||||||||

| GICLZ9 | 26.5 | 3500 | 70.71.75 | 142 | 315 | 270 | 200 | 225 | 142 | 18 | 0.94 | 100.1 |

| 80.85.90.95 | 172 | 18 | ||||||||||

| 100.110.120.125 | 212 | 18 | ||||||||||

| 130.140 | 252 | 18 | ||||||||||

| GICLZ10 | 42.5 | 3200 | 80.85.90.95 | 172 | 345 | 300 | 220 | 250 | 165 | 14 | 1.67 | 147.1 |

| 100.110.120.125 | 212 | 14 | ||||||||||

| 130.140.150 | 252 | 14 | ||||||||||

| 160 | 302 | 14 | ||||||||||

| GICLZ11 | 60.0 | 3000 | 100.110.120 | 212 | 380 | 330 | 260 | 285 | 180 | 14 | 2.98 | 206.3 |

| 130.140.150 | 252 | 14 | ||||||||||

| 160.170.180 | 302 | 14 | ||||||||||

| GICLZ12 | 80.0 | 2800 | 120 | 212 | 440 | 380 | 290 | 325 | 208 | 14 | 5.31 | 284.5 |

| 130.140.150 | 252 | 14 | ||||||||||

| 160.170.180 | 302 | 14 | ||||||||||

| 190.200 | 352 | 14 | ||||||||||

| GICLZ13 | 112 | 2300 | 140.150 | 252 | 480 | 420 | 320 | 360 | 238 | 15 | 9.26 | 402.0 |

| 160.170.180 | 302 | 15 | ||||||||||

| 190.200.220 | 352 | 15 | ||||||||||

| GICLZ14 | 160 | 2100 | 160.170.180 | 302 | 520 | 465 | 360 | 420 | 266 | 16 | 15.92 | 582.2 |

| 190.200.220 | 352 | 16 | ||||||||||

| 240.250 | 410 | 16 | ||||||||||

| GICLZ15 | 224 | 1900 | 190.200.220 | 352 | 580 | 510 | 400 | 450 | 278 | 17 | 25.78 | 778.2 |

| 240.250.260 | 410 | 17 | ||||||||||

| 280 | 470 | 17 | ||||||||||

| GICLZ16 | 355 | 1800 | 220 | 352 | 680 | 595 | 465 | 500 | 320 | 16.5 | 16.89 | 1071.0 |

| 240.250.260 | 410 | 16.5 | ||||||||||

| 280.300.320 | 470 | 16.5 | ||||||||||

| GICLZ17 | 400 | 1500 | 220 | 352 | 720 | 645 | 495 | 530 | 336 | 17 | 60.59 | 1210.0 |

| 240.250.260 | 410 | 17 | ||||||||||

| 280.300.320 | 470 | 17 | ||||||||||

| GICLZ18 | 500 | 1400 | 280.300.320 | 470 | 775 | 675 | 520 | 540 | 351 | 16.5 | 81.75 | 1475.0 |

| 340 | 550 | 16.5 | ||||||||||

| GICLZ19 | 630 | 1300 | 280.300.320 | 470 | 815 | 715 | 560 | 580 | 372 | 17 | 101.57 | 1603.0 |

| 340.360 | 550 | 17 | ||||||||||

| GICLZ20 | 710 | 1200 | 340.360.380 | 550 | 855 | 755 | 585 | 600 | 393 | 20 | 140.03 | 2033.0 |

| GICLZ21 | 900 | 1100 | 340.360.380 | 550 | 915 | 785 | 620 | 640 | 404 | 20 | 183.49 | 2385.0 |

| 400 | 650 | 20 | ||||||||||

| GICLZ22 | 950 | 950 | 340.360.380 | 550 | 960 | 840 | 665 | 680 | 415 | 20 | 235.04 | 2452.0 |

| 400.420 | 650 | 20 | ||||||||||

| GICLZ23 | 1120 | 900 | 380.400 | 550 | 1010 | 880 | 710 | 720 | 435 | 20 | 323.16 | 3332.0 |

| 400.420.450 | 650 | 20 | ||||||||||

| GICLZ24 | 1280 | 875 | 380 | 550 | 1050 | 925 | 730 | 760 | 445 | 22 | 387.97 | 3639.0 |

| 400.420.450.480 | 650 | 22 | ||||||||||

| GICLZ25 | 1400 | 850 | 400.420.450.480.500 | 650 | 1120 | 970 | 770 | 800 | 465 | 22 | 485.96 | 4073.0 |

| GICLZ26 | 1600 | 825 | 420.450.480.500 | 650 | 1160 | 990 | 800 | 850 | 475 | 22 | 573.64 | 4527.0 |

| 530 | 800 | 22 | ||||||||||

| GICLZ27 | 1800 | 800 | 450.480.500 | 650 | 1210 | 1060 | 850 | 900 | 479 | 22 | 789.74 | 5485.0 |

| 530.560 | 800 | 22 | ||||||||||

| GICLZ28 | 2000 | 770 | 480.500 | 650 | 1250 | 1080 | 890 | 960 | 517 | 28 | 960.26 | 6050.0 |

| 530.560.600.630 | 800 | 28 | ||||||||||

| GICLZ29 | 2800 | 725 | 500 | 650 | 1340 | 1200 | 960 | 1010 | 517 | 28 | 1268.98 | 7090.0 |

| 530.560.600.630 | 800 | 28 | ||||||||||

| GICLZ30 | 3500 | 700 | 560.600.630 | 800 | 1390 | 1240 | 1005 | 1070 | 525 | 28 | 1822.02 | 9264.0 |

| 670 | 900 | 28 |

(1)The quality and moment of inertia is a approximation calculated.

by The least diameter of axis length.

(2) D2≥465mm Seal ring are adopted by the circular surface felted by rubber.

(3) the axle hole sizes marked "*" in the table is only applied to half Coupling dz.

(4) allow orientation compensate 1e 30'.

(5) Allow radial compensate ΔY=0.026 ΔA.

As a core product in the mechanical transmission component product line of Raydafon, the GICLZ drum-shaped gear coupling consistently demonstrates outstanding performance in various industrial scenarios that require stable power transmission. This highly favored flexible drum-shaped gear coupling can not only effectively improve equipment operation efficiency but also accurately solve various common problems in the process of shaft connection, making it a preferred component for many industrial enterprises in the configuration of transmission systems.

In terms of torque transmission capacity, the GICLZ drum-shaped gear coupling has extremely prominent performance and can be called an excellent high-torque gear coupling. It can easily handle various heavy loads, with a transmission efficiency as high as 99.7%. This excellent performance enables it to play an irreplaceable role in low-speed and heavy-load working conditions in fields such as mining and metallurgy, providing reliable transmission guarantees for the stable production of these industries.

Moreover, the GICLZ drum-shaped gear coupling also has excellent ability in adapting to misalignments and is a powerful high-misalignment gear coupling. It can efficiently compensate for angular, radial, and axial misalignments. Especially its optimized angular displacement performance effectively improves the tooth surface contact condition. Compared with straight-tooth couplings, it greatly extends its own service life, reduces the equipment shutdown and maintenance time caused by coupling wear, and further enhances the operation continuity of the entire production system.

Strong durability and low maintenance costs are also significant advantages of this coupling from Raydafon. It is made of high-strength and durable materials, with low noise and low vibration during operation. It not only reduces its own wear rate but also alleviates the loss of connected equipment. It is a reliable flexible gear coupling for industrial use suitable for harsh environments such as chemical industry and renewable energy. In these fields with extremely high requirements for equipment performance, it brings stable performance and helps enterprises reduce equipment operation and maintenance costs.

In addition, the design of the GICLZ drum-shaped gear coupling also fully considers installation convenience and long-term cost control. Its compact structure, combined with strong load-bearing capacity, ensures efficient operation performance as an industrial gear coupling, which can support the long-term continuous operation of equipment without frequent maintenance interventions. This design concept is highly consistent with Raydafon's commitment to providing high-quality and interchangeable components for the global market, bringing more cost-effective transmission solutions to industrial enterprises around the world.

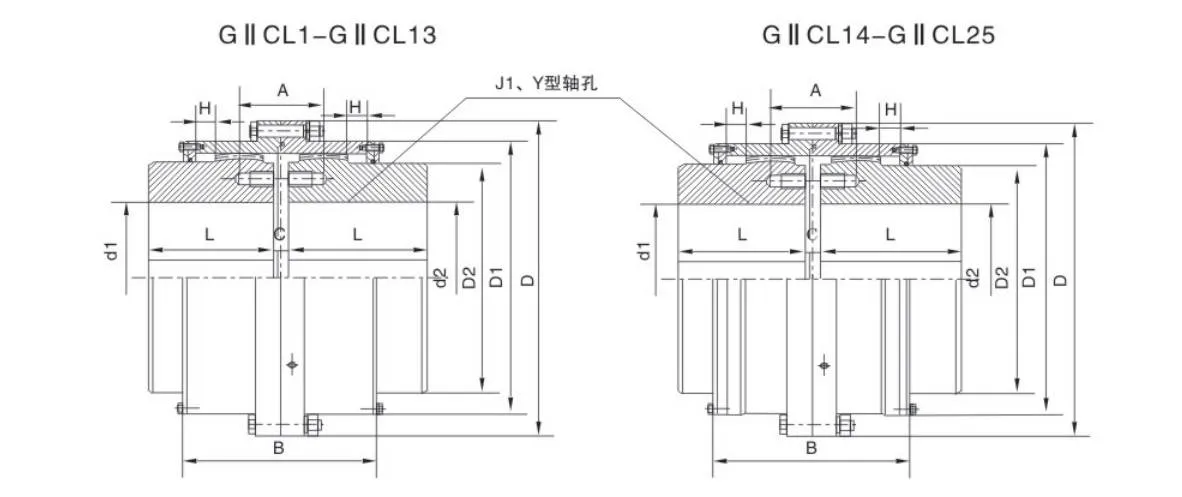

The GICLZ drum-shaped gear coupling produced by Raydafon strictly complies with the JB/ZQ standards for basic parameters and dimensions, and fully meets the requirements of JB/ZQ4382-86 Technical Specifications for Gear Couplings. It is a highly favored flexible drum-shaped gear coupling solution in the industrial transmission field. Specifically designed for connecting horizontal coaxial transmission shafting, this coupling can flexibly adapt to angular deviations and radial displacements of the shafting in actual working conditions. It also allows limited axial free movement of the shafting, easily coping with thermal expansion and contraction of the shafting caused by temperature changes during operation, thus providing reliable guarantee for the stable transmission of equipment.

The most prominent design feature of the GICLZ drum-shaped gear coupling lies in its drum-shaped external gear sleeve structure. This design enables the internal and external teeth of the coupling to achieve an optimal meshing state, significantly improving transmission stability. The coupling is made of high-quality steel with medium-hard tooth surfaces. Relying on its solid material and reasonable structure, it becomes a high-performance high-torque drum-shaped gear coupling, boasting excellent load-bearing capacity and capable of easily handling heavy-load transmission needs in industrial scenarios. To further enhance its performance, the tooth surfaces can undergo hardening treatment to reach a hardness standard of HRC ≥ 56. After hardening, the load-bearing capacity of the coupling is significantly enhanced while maintaining its lightweight characteristic and low rotational inertia, without imposing additional burdens on the shafting.

In terms of reliability, the GICLZ drum-shaped gear coupling also performs excellently. It is equipped with advanced lubrication structures and sealing components. Good lubrication can reduce tooth surface wear, while high-quality sealing can effectively prevent lubricating oil leakage and impurity intrusion. This not only extends the service life of the coupling but also simplifies daily maintenance. As a high-misalignment-compensation drum-shaped gear coupling, its symmetric structural design endows its components with excellent interchangeability, making the maintenance and replacement of parts more efficient and convenient. When the operating linear speed of the coupling exceeds 36 m/s, precise dynamic balancing treatment ensures stable operation of the equipment, avoiding vibrations caused by high-speed operation from affecting transmission accuracy.

To meet the connection requirements of different equipment, the GICLZ drum-shaped gear coupling offers a variety of shaft hole configuration schemes, covering multiple shaft hole combinations such as Type Y, Type Z1, and Type J1. No matter what kind of shafting connection scenario, a suitable installation method can be found. Raydafon has a comprehensive layout in the field of gear couplings. In addition to the GICLZ type, it also has multiple series of products including GICL, GⅡCL, GⅡCLZ, and NGCL. With its full-series product matrix, Raydafon has become a trustworthy flexible gear coupling supplier in the industrial field, and its products are widely used in transmission systems of various industries such as metallurgy, mining, chemical engineering, and electric power.

In terms of load-bearing capacity comparison, the GICLZ drum-shaped gear coupling demonstrates significant advantages. Under the conditions of the same inner sleeve outer diameter and maximum coupling outer diameter, its load-bearing capacity is 15%-20% higher than that of straight-tooth couplings, enabling it to transmit greater torque in a more compact installation space. In terms of misalignment compensation performance, this drum-shaped gear coupling is even more outstanding. When the radial displacement is zero, its angular displacement compensation can reach 1°30′, which is a 50% improvement compared with straight-tooth couplings. It can operate stably even in working conditions where the shafting alignment accuracy is not ideal. Moreover, under the same module, number of teeth, and tooth width, the drum-shaped tooth structure can achieve greater angular displacement compensation, with adaptability far exceeding that of straight-tooth couplings.

The drum-shaped tooth surface design of the GICLZ drum-shaped gear coupling can also optimize the contact state of the internal and external teeth. When there is angular displacement in the shafting, it effectively avoids edge extrusion on the tooth surfaces, reduces stress concentration, and at the same time enhances the wear resistance and friction resistance of the tooth surfaces, reduces noise during transmission, extends the maintenance interval of the equipment, reduces downtime for maintenance, and improves production efficiency. In addition, the two ends of the coupling's external gear sleeve adopt a bell-mouth shape. This detailed design makes the installation and disassembly of the coupling more convenient, saving man-hour costs during equipment assembly and maintenance.

With a transmission efficiency as high as 99.7%, the GICLZ drum-shaped gear coupling has become a preferred alternative to straight-tooth couplings worldwide. Raydafon has a complete production system, which can ensure that each GICLZ coupling has complete specifications and meets standards, providing users with stable and reliable products. As an efficient industrial drum-shaped gear coupling, it possesses both rigidity and flexibility but lacks elasticity. Therefore, it is not suitable for working conditions requiring vibration damping and buffering, nor can it be used in mechanical equipment that has strict requirements on shafting alignment accuracy. Users can make reasonable selections according to actual working condition needs.

⭐⭐⭐⭐⭐ Li Ming, Senior Engineer, Tianjin Heavy Machinery Co., Ltd.

For months now, we have installed Raydafon’s GICLZ Drum-Type Gear Coupling on the large-scale industrial equipment in our factory, and its actual performance has far exceeded our expectations. The drum gear design of this coupling is incredibly practical. Previously, the equipment always vibrated noticeably during operation—operators complained about loud noise and the machine "shaking". After replacing it with this coupling, the vibration amplitude has been reduced by more than half, making the entire equipment run steadily and smoothly. Moreover, its body is made of solid materials. The equipment in our workshop operates under heavy loads all year round, running continuously for over ten hours as a common routine. Yet, this industrial heavy-duty GICLZ drum-type gear coupling has never failed us; the tooth surface wear is extremely slight, and it still looks almost new when disassembled for inspection. Installation is also hassle-free—two people from our technical team finished it in less than an hour by following the instructions, no need to hire a third-party team. What’s more worth mentioning is Raydafon’s customer service. Earlier, when we had doubts about the installation clearance of the drum-type gear coupling during debugging, after consulting online, the engineer not only replied instantly but also sent a detailed debugging video. The service is exceptionally thoughtful, and the entire team highly recognizes this product.

⭐⭐⭐⭐⭐ James Mitchell, Maintenance Manager, New York Steel Works, USA

At our New York factory, Raydafon’s GICLZ Drum-Type Gear Coupling is definitely a "problem-solver". Previously, the steel rolling equipment in the factory had long been plagued by noise and vibration issues. Especially during high-torque operation, the coupling would drive the drive shaft to make a "buzzing" sound, forcing employees at nearby workstations to wear noise-canceling headphones. During maintenance, we also found frequent component loosening caused by vibration. Since replacing it with this high-torque GICLZ drum-type gear coupling, the situation has been completely improved. Its unique drum gear structure can cleverly disperse the stress during operation, not only reducing the equipment noise to within the compliance range but also minimizing component wear caused by vibration. Its installation is extremely simple—our maintenance team didn’t spend much time completing the replacement. After using it for such a long time, it remains stable whether handling high-intensity torque loads or coping with the impact during equipment start-up and shutdown, without any failures. Now, we not only continue to use it on existing equipment but also plan to fully adopt Raydafon’s industrial noise-reducing GICLZ drum-type gear coupling for the upcoming new production lines. It’s unbeatable in terms of cost-effectiveness and reliability.

⭐⭐⭐⭐⭐ Maria González, Operations Director, Madrid Industrial Group, Spain

Raydafon’s GICLZ Drum-Type Gear Coupling has been a great help to the production operations of our Madrid factory! The biggest problem with the couplings of other brands we used before was shaft misalignment—after the equipment operated for a period of time, the coupling always deviated from the motor shaft and the working machine shaft, resulting in reduced power transmission efficiency and frequent wear of connected components. We had to shut down the production line several times a month just for maintenance. After switching to this anti-misalignment GICLZ drum-type gear coupling, its drum gear design perfectly solves this pain point. It can automatically compensate for installation deviations within a certain range, and the shaft system can still maintain accurate alignment even when the equipment operates at high speed for a long time. Additionally, its impact resistance is excellent. The stamping equipment on our production line generates large impact force during operation, and this coupling can always buffer it steadily, keeping the entire production process running smoothly and stably. More importantly, the maintenance frequency has been reduced by two-thirds compared to before, which greatly minimizes the loss caused by production line shutdowns. In high-load industrial scenarios, it is definitely a reliable "must-have".

⭐⭐⭐⭐⭐ Pierre Lefevre, Engineering Manager, Paris Mechanical Solutions, France

After installing Raydafon’s GICLZ Drum-Type Gear Coupling on the equipment in our Paris factory, both the operation efficiency and stability have been elevated to a higher level. The drum gear design of this coupling comes with "flexibility"—it can not only efficiently absorb the impact load during equipment operation but also reduce the wear of connected gears and bearings. Previously, we had to replace vulnerable parts of the processing equipment every month, but now the replacement cycle has been extended to three months, significantly reducing the cost of consumables. The installation process is also trouble-free—our engineers completed the assembly in less than an hour by following the installation steps of GICLZ drum-type gear coupling in the manual, with no need for additional debugging. Up to now, the tooth surface of the coupling is still smooth without deformation or rust, and its durability is far superior to other brands we have used. For enterprises pursuing equipment reliability and production efficiency, this industrial high-efficiency GICLZ drum-type gear coupling is definitely an excellent choice.

Having been in the mechanical transmission components industry for over a decade, Raydafon started out in Hangzhou back in 2006 with a clear focus: "to deliver reliable transmission solutions." We don’t just simply manufacture products; instead, we concentrate on providing practical, high-performance solutions tailored to industrial scenarios across various sectors. Over the years, we’ve earned a solid reputation as a trustworthy gear coupling manufacturer among many clients, and our export business has grown steadily. Every coupling we produce adheres to international standards—all to ensure our clients can use our products with complete peace of mind.

Clients who’ve worked with us know that Raydafon’s standout strength lies in our high-torque gear couplings. Industrial sites are often harsh environments, where equipment operates under heavy loads for long stretches. Our high-torque gear couplings are specifically designed to handle such demanding conditions: they enable stable and efficient power transmission while minimizing equipment downtime for maintenance—saving clients a great deal of hassle. Take the flexible gear couplings we supply for heavy machinery, for example: we select only durable, high-quality materials during production and adopt advanced industry techniques. This ensures our products not only deliver top-tier performance but also boast a long service life. We never resort to the "low-price, low-quality" approach; instead, we strive to balance uncompromising quality with cost-effectiveness for our clients. That’s why so many industries in need of robust industrial gear coupling systems are willing to build long-term partnerships with us.

What’s more, Raydafon truly understands the ins and outs of "customization on demand." Every client has unique equipment, working conditions, and torque requirements—we never force a one-size-fits-all solution. Instead, we design tailored gear coupling solutions based on their specific needs. Whether it’s a standard model or a specialized variant that requires custom development, our modern manufacturing facility and R&D team conduct strict checks at every stage: from design and production to testing. We stay on top of quality control every step of the way to ensure all products meet international certifications. Choosing Raydafon means more than just purchasing a gear coupling; we also provide ongoing technical consulting support—clients can reach out to us anytime with questions—and we always deliver on time. It’s precisely because of this that we’ve maintained a solid foothold among gear coupling suppliers worldwide.

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Tel

+86-574-87168065

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Copyright © Raydafon Technology Group Co.,Limited All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |