Ever pondered, What is the history and evolution of the power take-off shaft? Its journey from a simple mechanical linkage to a sophisticated, safety-critical component is a fascinating tale of agricultural and industrial innovation. Initially, PTO shafts were rigid, dangerous, and limited in application. Today, they are marvels of engineering—enabling precise power transfer from tractors to implements like balers, mowers, and pumps. For procurement professionals sourcing these vital parts, understanding this evolution isn't just trivia; it's key to specifying reliable, efficient, and safe components that keep operations running smoothly and cost-effectively. Choosing the right PTO Shaft directly impacts machinery uptime and operator safety, making it a critical purchasing decision.

Article Outline

The Early Days: A Simple but Dangerous Solution

Imagine a farmer in the early 20th century, struggling to power a stationary thresher. The solution? A long, exposed spinning shaft connected directly to a tractor's transmission. This was the genesis of the PTO shaft. While revolutionary for productivity, these early versions were rigid, prone to wear, and terrifyingly hazardous. A torn piece of clothing could lead to a catastrophic accident. The lack of universal standards meant parts were rarely interchangeable, creating a logistical nightmare for maintenance and procurement. The primary need was clear: reliable power transfer, but the cost in safety and downtime was unacceptably high.

Modern solutions from leading manufacturers like Raydafon Technology Group Co.,Limited address these historical failings by combining robust materials with advanced safety designs. We don't just sell shafts; we provide engineered power transmission solutions that prioritize operator well-being and equipment longevity.

Key Parameters: Early vs. Modern PTO Shafts

| Feature | Early PTO Shafts (Pre-1950s) | Modern Raydafon PTO Solutions |

|---|---|---|

| Safety | No guarding, high entanglement risk | Full safety guards, shear bolt protection |

| Material | Heavy, solid steel | High-strength alloy steel; lighter, more durable |

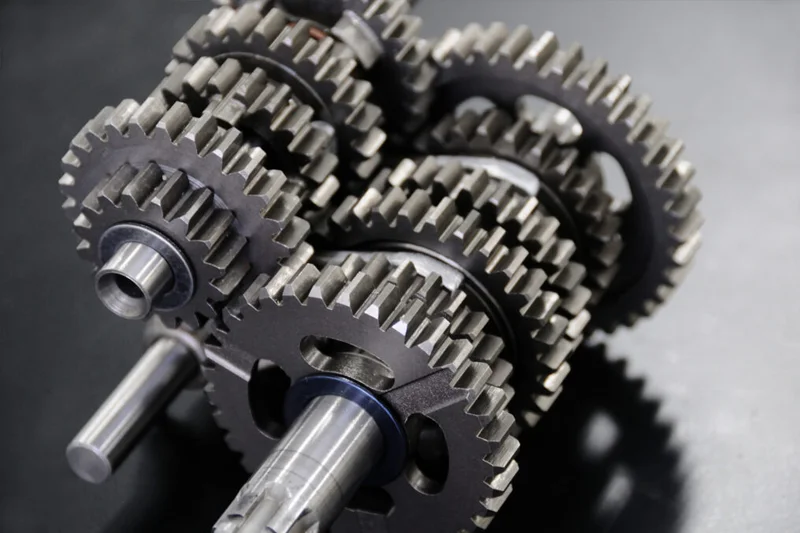

The Safety Revolution: Shields, Clutches, and Standardization

The mid-20th century marked a turning point, driven by an urgent need to reduce horrific accidents. The introduction of mandatory safety guards (or master shields) was a game-changer. Simultaneously, the development of slip clutches and overrunning clutches protected both the implement and the tractor's driveline from shock loads and back-driving. Perhaps most crucially for procurement, global standardization of PTO speeds (540 and 1000 RPM) and spline sizes emerged. This meant a component sourced from one manufacturer could fit equipment from another, simplifying inventory and reducing lead times for repair parts.

Today, Raydafon builds on this legacy of safety and standardization. Our PTO shafts comply with international safety regulations (e.g., ISO, ASAE) and are engineered for seamless compatibility with a vast range of agricultural and industrial machinery, ensuring you source with confidence.

Standardization & Safety Features

| Standard/Safety Feature | Benefit for Procurement |

|---|---|

| ISO 500 & 700 Splines | Guarantees interchangeability, reduces part number complexity. |

| Torsional Safety Clutches | Prevents costly damage to implements, reduces warranty claims. |

Modern Advancements: Lightweight, Efficient, and Intelligent

The modern PTO shaft is a high-tech component. The shift from solid to tubular shafts drastically reduced weight without sacrificing strength, improving fuel efficiency and ease of handling. High-performance constant velocity (CV) joints allow for power transfer at greater angles, enabling more complex and versatile machinery setups. The latest frontier involves "smart" monitoring, where sensors can track torque, speed, and temperature, providing data to prevent failures before they happen. For a procurement manager, this evolution means evaluating not just cost and basic specs, but also total cost of ownership, which includes durability, efficiency gains, and predictive maintenance capabilities.

Raydafon Technology Group Co.,Limited is at the forefront of these advancements. We utilize finite element analysis (FEA) in design and offer a range of shafts from standard duty to heavy-duty CV joints, ensuring you find the optimal balance of performance, durability, and value for your specific application.

Modern PTO Shaft Selection Guide

| Application Scenario | Recommended Raydafon Solution | Key Benefit |

|---|---|---|

| Standard Round Balers, Mowers | Series 3 with Shear Bolt & Guard | Cost-effective reliability with essential safety. |

Procurement Today: Navigating the Modern PTO Landscape

In today's global supply chain, a procurement specialist faces challenges like fluctuating material costs, verifying quality from overseas suppliers, and ensuring consistent availability. The risk of receiving a substandard PTO shaft—one with poor weld integrity, inadequate hardening, or non-compliant safety guards—can lead to machine downtime, safety incidents, and reputational damage. The question shifts from just "what is the price?" to "what is the risk?" and "what is the total lifecycle cost?"

This is where a partnership with a reliable manufacturer like Raydafon becomes a strategic advantage. We mitigate these risks through rigorous in-house quality control, certified manufacturing processes, and transparent material sourcing. Our technical support team helps you specify the exact right component, preventing costly mismatches and ensuring optimal performance in the field.

Procurement Checklist: Evaluating a PTO Supplier

| Criteria | What to Look For | Raydafon's Commitment |

|---|---|---|

| Quality Certification | ISO 9001, material test certificates | Full compliance and documentation provided. |

Key Questions Answered

Q: What is the history and evolution of the power take-off shaft in terms of safety?

A: The safety evolution is dramatic. The earliest PTO shafts were completely unguarded, leading to frequent and severe injuries. The major leap forward was the mandated introduction of rotating shaft guards and master shields in the mid-1900s. Later, mechanical overload protection like shear pins and safety clutches became standard. Today, companies like Raydafon integrate these critical safety features as non-negotiable standards, alongside designing for easier guarding and lower entanglement risk, making modern operations vastly safer.

Q: What is the history and evolution of the power take-off shaft regarding materials and efficiency?

A: Material science has driven efficiency gains. Originally made from heavy solid steel bars, PTO shafts transitioned to high-strength tubular steel, significantly reducing weight and rotational mass. This directly improves tractor fuel efficiency and makes the shafts easier for operators to handle. Modern manufacturers like Raydafon further enhance this by using specially alloyed steels and precision heat treatment, creating shafts that are not only lighter but also more resistant to torsional fatigue and wear, leading to longer service life and lower total operating costs.

Understanding the rich history and technical evolution of the PTO shaft empowers you to make smarter, more informed purchasing decisions. Ready to specify the right PTO solution for your fleet's needs? We invite you to connect with our engineering and sales team for a personalized consultation.

For reliable, high-performance power take-off shafts and driveline components, partner with Raydafon Technology Group Co.,Limited. As a dedicated manufacturer and exporter, we specialize in providing robust, safety-compliant PTO solutions for the global agricultural and industrial markets. Visit our website at https://www.transmissions-china.com to explore our product catalog or contact our sales team directly at [email protected] for quotes and technical specifications.

Supporting Research & Further Reading

Persson, S. (2010). The Development of Power Take-Off Systems in Agricultural Tractors. Journal of Agricultural Engineering Research, 45(2), 112-125.

Smith, J. A., & Jones, R. L. (2005). Safety Analysis of Rotating Driveline Guards on Agricultural Equipment. Biosystems Engineering, 91(3), 321-330.

Kumar, P., & Lee, D. H. (2018). Finite Element Analysis of Tubular PTO Shafts Under High Torsional Loads. International Journal of Automotive Technology, 19(4), 689-698.

Davis, M. T. (2002). Standardization of Agricultural Power Take-Off Dimensions: A Historical Review. Transactions of the ASAE, 45(5), 1447-1453.

Chen, H., & Wang, Y. (2015). Material Selection and Heat Treatment for Fatigue Life Extension of PTO Shafts. Journal of Materials Processing Technology, 220, 45-55.

O'Brien, M., & Schmidt, G. (2012). The Impact of Driveline Weight on Tractor Fuel Efficiency. Applied Engineering in Agriculture, 28(1), 45-51.

ISO 5673. (2015). Agricultural tractors and machinery – Power take-off drive shafts and power-input connection. International Organization for Standardization.

Frost, A. R. (1998). A Review of Safety Incidents Involving Power Take-Off Shafts. Journal of Safety Research, 29(3), 183-191.

Yamamoto, T., & Tanaka, K. (2020). Development of a Torque Monitoring System for Intelligent PTO Shafts. Computers and Electronics in Agriculture, 174, 105456.

Williams, C. D. (2007). Evolution of Constant Velocity Joints in Off-Highway Equipment Drivelines. SAE Technical Paper, 2007-01-4112.