QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

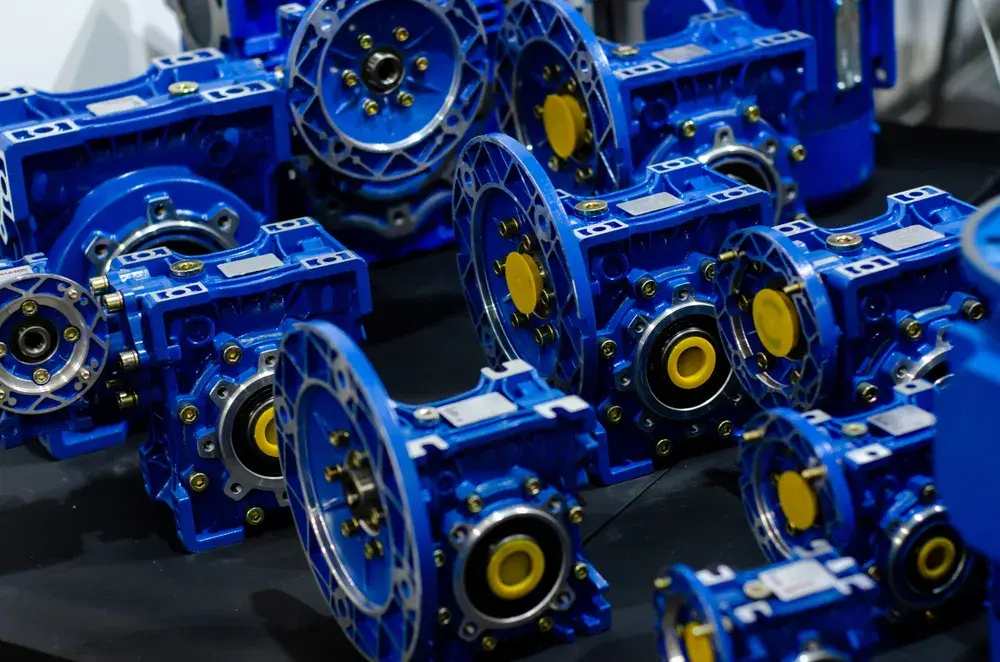

| Product Name: | EP-NMRV worm gearbox |

| Brand: | EPT |

| Model: | EP-NMRV/EP-NMRV..F/EP-NMRV..VS/EP-NRV/EP-NRV..F/EP-NRV..VS 025, 030, 040, 050, 063, 075, 090, 110, 130, 150 |

| Input Configurations: | Equipped with Electric Motors (AC Motor, DC Motor, Servo Motor…), |

| IEC-normalized Motor Flange, | |

| Solid Shaft Input, | |

| Worm Shaft Tail Extension Input | |

| Output Configurations: | Keyed Hollow Shaft Output, |

| Hollow Shaft with Output Flange, | |

| Plug-in Solid Shaft Output | |

| Ratio: | 1:7.5, 10, 15, 20, 25, 30, 40, 50, 60, 80, 100 |

| Input Power: | 0.12kw, 0.18kw, 0.25kw, 0.37kw, 0.55kw, 0.75kw, 1.1kw, 1.5kw, 2.2kw, 4kw, 5.5kw, 7.5kw, … |

| Color: | Blue/Black/Grey Or On Customer Request |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear-Tin Copper | |

| Worm Shaft: 20CrMn Ti with carburizing and quenching | |

| Out Shaft-chromium steel-45# | |

| Bearing: | C&U/QC/HRB brand or upon customer request |

| Seal: | SKF/NAK/KSK brand or upon customer request |

| Viton oil seal ensures high-temperature resistance, anti-oxidation, and less oil leakage | |

| Lubricant: | Synthetic/Mineral |

| IEC Flange: | 56B14, 63B14, 63B5, 63B5, 71B14, 80B14, etc |

| Warranty: | 1 Year |

| Packing: | Carton/Wooden pallet/ Wooden Case |

| Place of origin: | Hangzhou, China |

| Supply Ability: | 15000pcs/month |

| Quality Control: | ISO9001:2015 certified |

| Loading Port: | Ningbo/Shanghai |

| Models | Rated Power | Rated Ratio | Input Hole Dia. | Input Shaft Dia. | Output Hole Dia. | Output Shaft Dia. |

| EP-NMRV030 | 0.06KW~0.25KW | 7.5~80 | Φ9(Φ11) | Φ9 | Φ14 | Φ14 |

| EP-NMRV040 | 0.09KW~0.55KW | 7.5~100 | Φ9(Φ11, Φ14) | Φ11 | Φ18(Φ19) | Φ18 |

| EP-NMRV050 | 0.12KW~1.5KW | 7.5~100 | Φ11(Φ14, Φ19) | Φ14 | Φ25(Φ24) | Φ25 |

| EP-NMRV063 | 0.18KW~2.2KW | 7.5~100 | Φ14(Φ19, Φ24) | Φ19 | Φ25(Φ28) | Φ25 |

| EP-NMRV075 | 0.25KW~4.0KW | 7.5~100 | Φ14(Φ19, Φ24, Φ28) | Φ24 | Φ28(Φ35) | Φ28 |

| EP-NMRV090 | 0.37KW~4.0KW | 7.5~100 | Φ19(Φ24, Φ28) | Φ24 | Φ35(Φ38) | Φ35 |

| EP-NMRV110 | 0.55KW~7.5KW | 7.5~100 | Φ19(Φ24, Φ28, Φ38) | Φ28 | Φ42 | Φ42 |

| EP-NMRV130 | 0.75KW~7.5KW | 7.5~100 | Φ24(Φ28, Φ38) | Φ30 | Φ45 | Φ45 |

| EP-NMRV150 | 2.2KW~15KW | 7.5~100 | Φ28(Φ38, Φ42) | Φ35 | Φ50 | Φ50 |

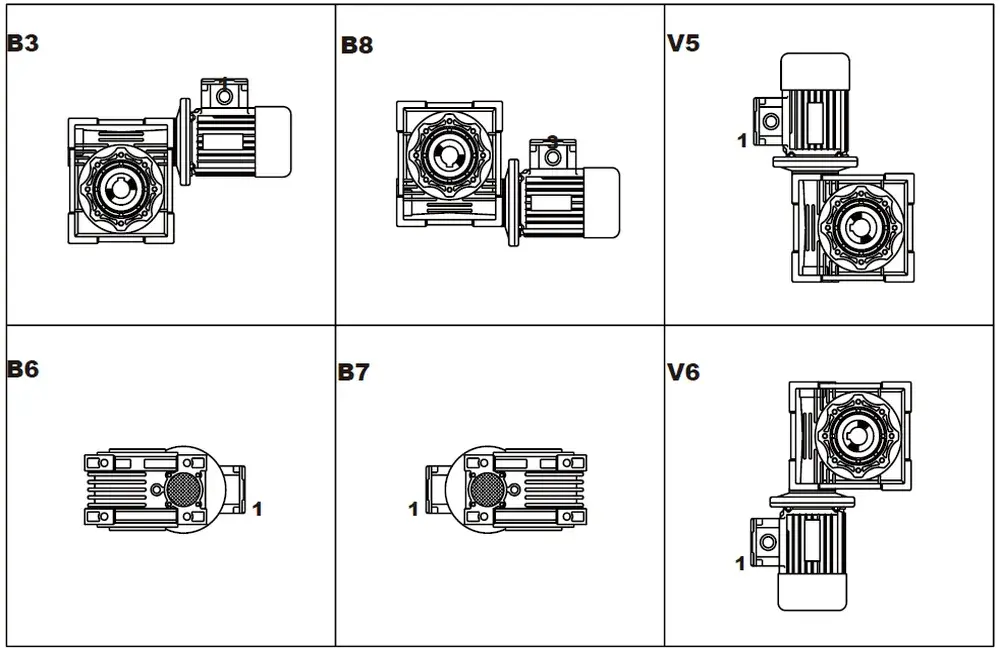

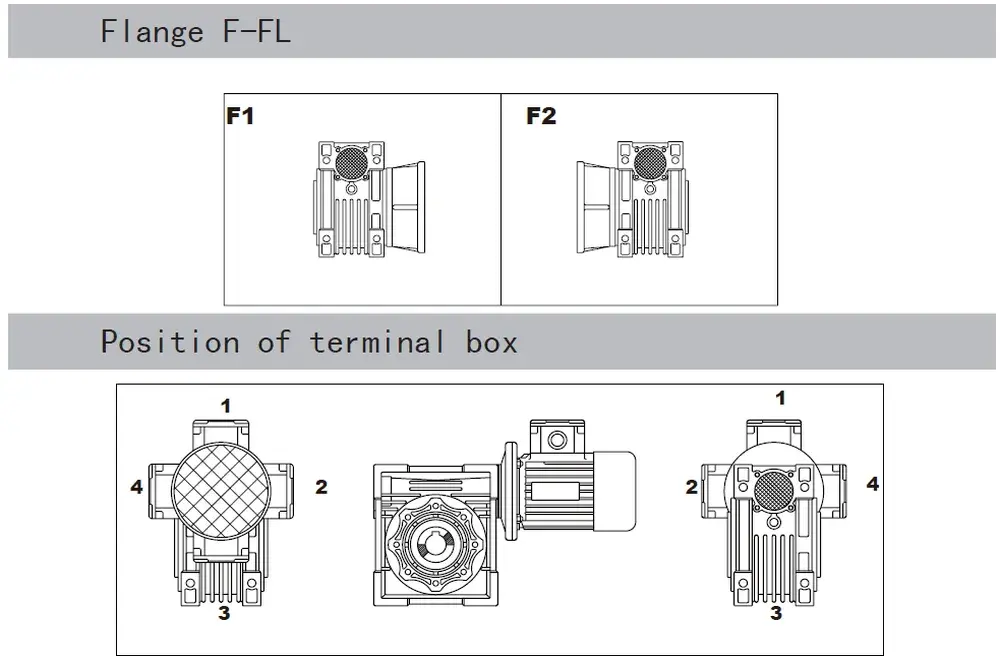

| EP-NMRV-063-30-VS-F1(FA)-AS-80B5-0.75KW-B3 | |||

| EP-NMRV | Worm geared motor | ||

| EP-NRV | Worm reduction unit | ||

| 063 | center distance | ||

| 30 | Reduction ratio | ||

| VS | Double input shaft | F1(FA) | Output flange |

| AS | Single output shaft | AB | Double output shaft |

| PAM | Fitted for motor coupling | 80B5 | Motor mounting facility |

| 0.75KW | Electric motor power | B3 | Mounting position |

|

Center Distance A |

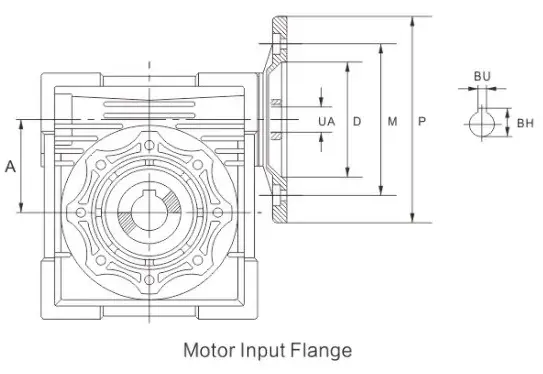

Motor Flange | UA The Hole Diameter of Shaft | |||||||||||||||

| PAM | D | M | P | BU | BH | i Transmission Ratio | |||||||||||

| EC | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | 80 | 100 | ||||||

| 25 | 56B14 | 50 | 65 | 80 | 3 | 10.4 | 9 | 9 | 9 | 9 | - | 9 | 9 | 9 | 9 | - | - |

| 30 | 63B5 | 95 | 115 | 140 | 4 | 12.8 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | - | - | - |

| 63B14 | 60 | 75 | 90 | ||||||||||||||

| 56B5 | 80 | 100 | 120 | 3 | 10.4 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | - | |

| 56B14 | 50 | 65 | 80 | ||||||||||||||

| 40 | 71B5 | 110 | 130 | 160 | 5 | 16.3 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | - | - | - | - |

| 71B14 | 70 | 85 | 105 | ||||||||||||||

| 63B5 | 95 | 115 | 140 | 4 | 12.8 | - | - | - | 11 | 11 | 11 | 11 | 11 | 11 | 11 | - | |

| 63B14 | 60 | 75 | 90 | ||||||||||||||

| 56B5 | 80 | 100 | 120 | 3 | 10.4 | - | - | - | - | - | - | - | 9 | 9 | 9 | 9 | |

| 50 | 80B5 | 130 | 165 | 200 | 6 | 21.8 | 19 | 19 | 19 | 19 | 19 | 19 | - | - | - | - | - |

| 80B14 | 80 | 100 | 120 | ||||||||||||||

| 71B5 | 110 | 130 | 160 | 5 | 16.3 | - | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | - | |

| 71B14 | 70 | 85 | 105 | ||||||||||||||

| 63B5 | 95 | 115 | 140 | 4 | 12.8 | - | - | - | - | - | - | 11 | 11 | 11 | 11 | 11 | |

| 63 | 90B5 | 130 | 165 | 200 | 8 | 27.3 | 24 | 24 | 24 | 24 | 24 | 24 | - | - | - | - | - |

| 90B14 | 95 | 115 | 140 | ||||||||||||||

| 80B5 | 130 | 165 | 200 | 6 | 21.8 | - | - | 19 | 19 | 19 | 19 | 19 | 19 | 19 | - | - | |

| 80B14 | 80 | 100 | 120 | ||||||||||||||

| 71B5 | 110 | 130 | 160 | 5 | 16.3 | - | - | - | - | - | - | 14 | 14 | 14 | 14 | 14 | |

| 71B14 | 70 | 85 | 105 | ||||||||||||||

| 75 | 100/1128 | 5180 | 215 | 250 | 8 | 31.3 | 28 | 28 | 28 | - | - | - | - | - | - | - | - |

| 00Y112B14 | 110 | 130 | 160 | ||||||||||||||

| 90B5 | 130 | 165 | 200 | 8 | 27.3 | - | 24 | 24 | 24 | 24 | 24 | 24 | - | - | - | - | |

| 90B14 | 95 | 115 | 140 | ||||||||||||||

| 80B5 | 130 | 165 | 200 | 6 | 21.8 | - | - | - | - | 19 | 19 | 19 | 19 | 19 | 19 | 19 | |

| 80B14 | 80 | 100 | 120 | ||||||||||||||

| 90 | 100V112B5 | 180 | 215 | 250 | 8 | 31.3 | 28 | 28 | 28 | 28 | 28 | 28 | - | - | - | - | - |

| 100V112B14 | 110 | 130 | 160 | ||||||||||||||

| 90B5 | 130 | 165 | 200 | 8 | 27.3 | - | - | - | 24 | 24 | 24 | 24 | 24 | 24 | - | - | |

| 90B14 | 95 | 115 | 140 | ||||||||||||||

| 80B5 | 130 | 165 | 200 | 6 | 21.8 | - | - | - | - | - | - | - | 19 | 19 | 19 | 19 | |

| 80B14 | 80 | 100 | 120 | ||||||||||||||

| 110 | 132B5 | 230 | 265 | 300 | 10 | 41.1 | 38 | 38 | 38 | 38 | - | - | - | - | - | - | - |

| 100/112B5 | 180 | 215 | 250 | 8 | 31.3 | - | 28 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | - | - | |

| 90B5 | 130 | 165 | 200 | 8 | 27.3 | - | - | - | - | - | - | 24 | 24 | 24 | 24 | 24 | |

| 130 | 132B5 | 230 | 265 | 300 | 10 | 41.1 | 38 | 38 | 38 | 38 | 38 | 38 | 38 | - | - | - | - |

| 100/112B5 | 180 | 215 | 250 | 8 | 31.3 | - | - | - | - | 28 | 28 | 28 | 28 | 28 | 28 | 28 | |

| 150 | 160B5 | 250 | 300 | 350 | 12 | 45.3 | 42 | 42 | 42 | 42 | 42 | - | - | - | - | - | - |

| 132B5 | 230 | 265 | 300 | 10 | 41.3 | - | - | - | 38 | 38 | 38 | 38 | 38 | 38 | - | - | |

| 100/112B5 | 180 | 215 | 250 | 8 | 31.3 | - | - | - | - | - | - | - | 28 | 28 | 28 | 28 | |

|

|

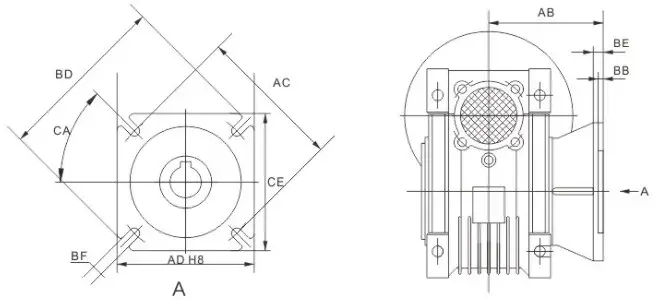

25 | 30 | 40 | 50 | 63 | 75 | 90 | 110 | 130 | 150 |

| AB | 45 | 54.5 | 67 | 90 | 82 | 102 | 111 | 131 | 140 | 155 |

| AC | 55 | 68 | 80 | 85 | 150 | 165 | 175 | 230 | 255 | 255 |

| AD | 40 | 50 | 60 | 70 | 115 | 130 | 152 | 170 | 180 | 180 |

| BB | 3 | 4 | 4 | 5 | 6 | 6 | 6 | 6 | 6 | 7 |

| BD | 75 | 80 | 110 | 125 | 180 | 200 | 210 | 280 | 320 | 320 |

| BE | 6 | 6 | 7 | 9 | 10 | 13 | 13 | 15 | 15 | 15 |

| BF | 6.5(n.4) | 6.5(n.4) | 9(n.4) | 11(n.4) | 11(n.4) | 14(n.4) | 14(n.4) | φ14(n.8) | φ16(n.8) | φ16(n.8) |

| CA | 45° | 45° | 45° | 45° | 45° | 45° | 45° | 45° | 22.5° | 22.5° |

| CE | 70 | 70 | 95 | 110 | 142 | 170 | 200 | 260 | 290 | 290 |

|

|

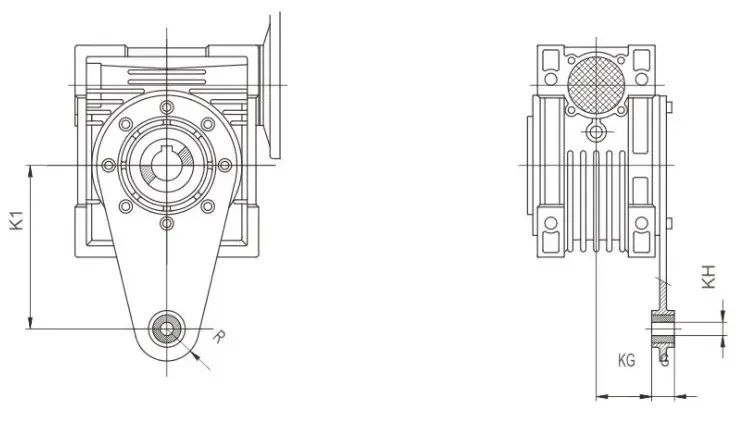

K1 | G | KG | KH | R |

| 025 | 70 | 14 | 17.5 | 8 | 15 |

| 030 | 85 | 14 | 24 | 8 | 15 |

| 040 | 100 | 14 | 31.5 | 10 | 18 |

| 050 | 100 | 14 | 38.5 | 10 | 18 |

| 063 | 150 | 14 | 49 | 10 | 18 |

| 075 | 200 | 25 | 47.5 | 20 | 30 |

| 090 | 200 | 25 | 57.5 | 20 | 30 |

| 110 | 250 | 30 | 62 | 25 | 35 |

| 130 | 250 | 30 | 69 | 25 | 35 |

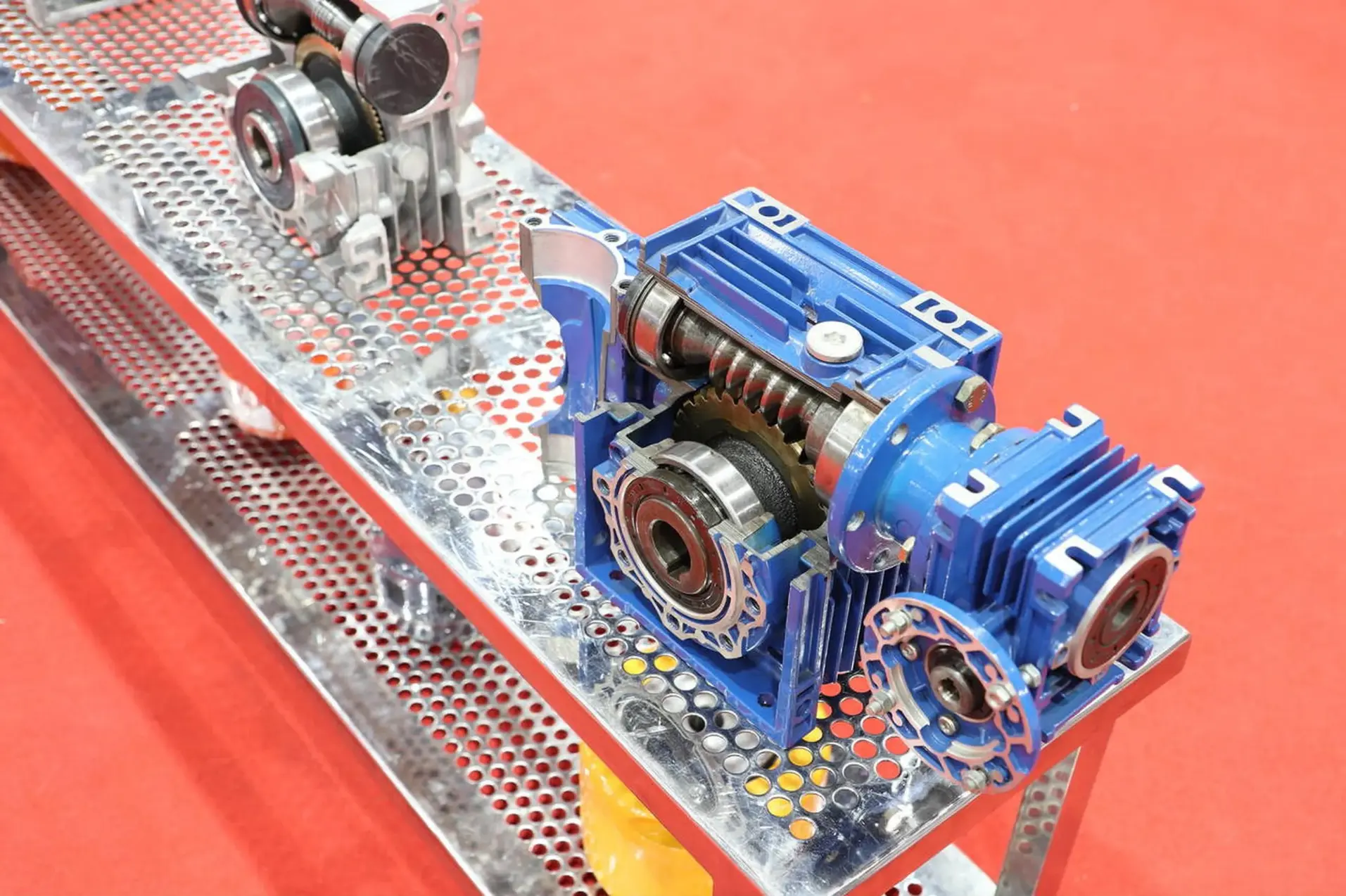

The EP-NMRV Worm Gearbox with Output Flange has a housing made of a strong aluminium alloy that is light and resistant to corrosion. It can work well for a long time in industrial settings with a lot of dust, chemicals, or humidity. Its worm gear gear gearbox system is small and can produce a lot of torque in a small space. It works best with automation equipment, conveyor systems, and packaging machines that don't have a lot of room. The EP-NMRV worm gearbox has an output flange that makes installation even easier by optimising the flange output structure. Users can choose the best way to connect based on the needs of the equipment, which cuts down on the time and money needed to install it. The worm wheel and worm, which are the main parts of the reducer, are made with high surface accuracy and a great meshing state.

The noise and vibration that happen while the machine is running are greatly reduced, making the working environment quieter and smoother. The product supports the idea of modular design and offers a range of installation options, including horizontal, vertical, and side-mounted installation. This means that it can easily fit into the layout needs of different mechanical systems. It is important to note that the EP-NMRV worm gearbox has a self-locking feature that works under certain reduction ratio conditions. This feature can help stop load reversal. It is especially good for uses that need a lot of safety, like conveyor belts with big incline angles and lifting equipment.

The EP-NMRV worm gearbox takes into account the need for long-lasting materials when choosing them. The worm wheel is made of bronze that won't wear out easily, and the worm is made of steel that has been heat-treated. When used with high-performance lubricants, it greatly increases the equipment's lifespan and cuts down on daily maintenance. It can reduce things from 5:1 to 100:1. Users can set the right gearbox parameters based on the conditions of their work. Many industries, like food processing, textile machinery, metallurgical equipment, printing equipment, and logistics sorting systems, have used it a lot. The lubricating oil sealing system is designed in a way that is both scientifically sound and reasonable to stop leaks and keep the equipment running well after long periods of continuous use.

The product meets all of the standards set by the ISO9001 quality certification system. There is strict quality control throughout the entire production process, from getting the raw materials to delivering the finished product. Precise testing makes sure that the product's performance is stable and consistent. The EP-NMRV worm gearbox's heat dissipation performance has been professionally improved, and the housing design effectively increases the area for heat dissipation. This means that it can keep a stable operating temperature even when it is under a lot of stress or running for a long time. This reducer works well in a wide range of situations. It can power dynamic equipment that needs to start and stop often, or heavy machinery that needs to run continuously for a long time. It can meet all of the user's actual application needs.

Worm gearboxes have shown strong applicability in the industrial field due to their unique transmission mechanism. This type of reducer achieves power transmission through the meshing of the worm wheel and the worm. Its biggest feature is that it can output large torque with a compact structure, while achieving low-noise operation with the help of smooth tooth engagement. This feature makes it a core transmission component for many precision equipment - for example, in the production line of electronic components, the start and stop accuracy of the conveyor belt is required to reach the millimeter level. The worm gearbox achieves stable transmission through precise gear engagement to avoid displacement of components due to vibration during transmission; in food packaging machinery, its self-locking function can prevent the filling equipment from backflowing materials when the power is suddenly cut off, ensuring the hygiene and safety of the production line.

Key applications in the field of new energy

In the wind power generation scenario, the worm gearbox is responsible for driving the yaw system. When the wind direction changes, the reducer needs to push the wind turbine cabin weighing tens of tons to turn slowly, and its high torque output characteristics play an important role here. Actual data from an offshore wind farm shows that the reducer with bronze worm gear has been running continuously in a salt spray environment for 5 years, and the gear wear is still controlled within 0.1mm, which significantly reduces the frequency of high-altitude maintenance. In the solar tracking system, the reducer has an angle control accuracy of 0.01°, which extends the average daily light exposure time of the photovoltaic panel by 1.5 hours, and the system power generation efficiency is improved by about 12%.

Reliable support in heavy machinery

When lifting reinforced concrete components, tower cranes used in construction have extremely high requirements for the safety of the transmission system. The self-locking function of the worm gearbox becomes the key here - when the lifting mechanism stops running, the meshing surface of the worm and the worm wheel can form a mechanical lock to prevent the heavy object from falling due to a brake system failure. Test data from a construction machinery manufacturer shows that under a 30° tilt condition, a reducer equipped with a self-locking function can withstand an impact force exceeding 1.8 times the rated load without reversing. In addition, in the pitch mechanism of the port container crane, its compact structural design reduces the volume of the transmission box by 40% compared with the traditional gear box, effectively reducing the windward area of the equipment.

Customized applications for special scenarios

The rotating frame of the medical CT equipment needs to complete 360° uniform rotation within 0.5 seconds. The worm gear reducer outputs a stable speed of 0.5rpm and cooperates with the encoder to achieve angle control with an error of less than 0.1° to ensure the clarity of the image scan. In large-scale stage performances, multiple sets of reducers for the lifting stage need to run synchronously, and their low noise characteristics (operating noise ≤55dB) avoid interference with the performance sound effects. A stage machinery engineer at a theater mentioned: "We used a worm gear reducer to drive a 12-meter-wide rotating stage in a musical performance, and the actors on the stage could not feel the vibration of the equipment at all." From industrial production lines to new energy equipment, from construction machinery to precision medical equipment, worm gearboxes continue to expand their application boundaries through continuous optimization of material processes (such as the pairing of wear-resistant bronze worm wheels and hardened steel worms) and structural designs. In high-end fields such as semiconductor wafer inspection equipment and aerospace simulation turntables, its transmission accuracy has been improved to the arc second level, becoming an important supporting component for promoting the development of high-end manufacturing.

As a Raydafon customer, I am very satisfied with the Worm Gearbox I purchased! This product is solidly made, runs very smoothly on our equipment, has strong torque output, and is basically noiseless. After installing it, the efficiency of the conveyor line in our workshop has increased a lot, and the number of downtimes has also decreased. Your team's service attitude warms my heart. From the initial model selection to the later installation guidance, they were very patient and helped me solve many problems.I am very glad to choose Raydafon, and I feel that this money is worth it! In the future, our company will definitely come to you if we have similar needs. I hope you will continue to maintain this quality and service and bring good products to more customers! Name: James Carter

Hello, Raydafon team! I am Michael Evans, an Australian customer. I purchased your Worm Gearbox last year and it has been running beyond my expectations. This worm gearbox has been running in our feed production line for 8 months. Even in a high dust environment, the gears mesh smoothly and the transmission efficiency is 30% higher than the previous equipment. I was particularly impressed by the installation process - the 3D installation drawings provided with the box were very clear, and our technicians completed the equipment docking in just 2 hours, which is half the time of conventional gearboxes. I am very impressed by your service response speed: when the order was placed during the Australian holiday, the customer service team still confirmed the technical parameters within 24 hours; when the equipment was shipped, a video of the entire process of shockproof packaging was specially filmed, and the cushioning material filled in the wooden box ensured that the equipment was intact after the cross-ocean transportation. At present, this transmission system has become a core component of our production line, and I look forward to working with you in more agricultural equipment upgrades in the future!

I am Carlos García from Spain. I know what is truly reliable after using Raydafon's Worm Gearbox! I was attracted by the details of your product at first, and found that the workmanship is really good after I got it. The joints of the box body are tightly fitted, and the worm gears are particularly tight. After installing it on our conveyor equipment, it runs smoothly. The previous sense of frustration when the equipment started up has completely disappeared, and even the noise is much smaller. In the workshop, the running sound is almost inaudible from a long distance. What impressed me most was your professional service. Before placing an order, I didn't understand the parameter matching very well. The technicians not only patiently answered, but also took the initiative to recommend a suitable model according to our working conditions. In the middle, the equipment needed to adjust the installation angle. I sent an email to ask for precautions, and I received a detailed operating guide and diagram on the same day. Now this gearbox has been used for nearly half a year, and there has been no problem, and even daily maintenance is very simple. Thank you very much for providing such a good product. I will definitely come again if I need it in the future!

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Tel

+86-574-87168065

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Copyright © Raydafon Technology Group Co.,Limited All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |