QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

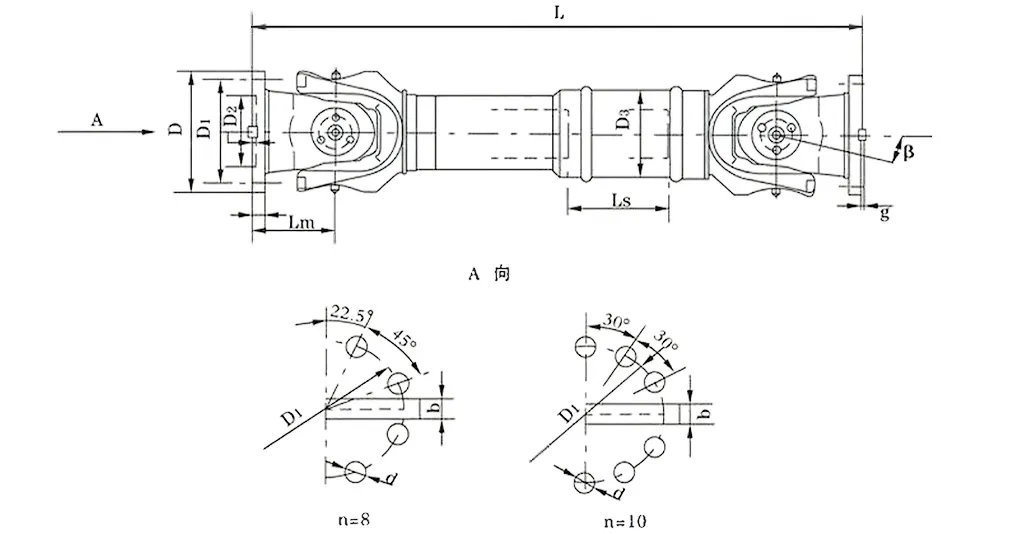

Raydafon’s SWC-DH Short Flex Welding Type Universal Coupling is built to connect misaligned shafts in heavy-duty gear—think rolling mills, hoists, and steel processing machines. It’s a compact short flex universal coupling, with a gyration diameter that ranges from 45mm to 390mm. Even when shafts are off by up to 25 degrees (angular misalignment), it still moves torque efficiently—maxing out at 1000 kN·m, which fits right in with heavy equipment’s power needs.

We make it with high-strength 35CrMo steel and add four needle bearings, so it holds up under heavy loads. That’s why it’s a solid pick for industrial machinery universal couplings, and works great as heavy equipment welded universal couplings in spots where loads stay high nonstop. Its short-flex design is perfect for machines with little room for axial movement, too—gives a tough transmission fix for tough industrial spaces.

Raydafon’s a China-based manufacturer with ISO 9001 certification, so we stick to strict quality rules for every SWC-DH universal coupling. The cross shaft gets a chrome plate to fight corrosion, so it lasts even when conditions are harsh. The welded yoke makes installation easier, too—just line up the shafts right, and it works at its best. You’ll find it on gear in metallurgy, mining, and crane systems, no problem.

Plus, this coupling comes in different sizes and torque ratings. If you need a custom universal coupling for industrial machinery—say, for harvesters or other specific gear—we can tailor it to your needs, and the price stays competitive. We’ve got the manufacturing know-how to make this short flex coupling cut down on equipment downtime, so your machines run more reliably overall.

| No. | Gyration diameter D mm | Nominal torque Tn KN·m | Axes fold angle β (°) | Weary torque Tf KN·m | Flex quantity Ls mm | Size (mm) | Rotating inertia kg.m2 | Weight (kg) | |||||||||||

| Lmin | D1 (js11) | D2 (H7) | D3 | Lm | n-d | k | t | b (h9) | g | Lmin | Increase 100mm | Lmin | Increase 100mm | ||||||

| SWC180DH1 | 180 | 20 | 10 | ≤25 | 75 | 650 | 155 | 105 | 114 | 110 | 8-17 | 17 | 5 | - | - | 0.165 | 0.0070 | 58 | 2.8 |

| SWC180DH2 | 55 | 600 | 0.162 | 56 | |||||||||||||||

| SWC180DH3 | 40 | 550 | 0.160 | 52 | |||||||||||||||

| SWC225DH1 | 225 | 40 | 20 | ≤15 | 85 | 710 | 196 | 135 | 152 | 120 | 20 | 5 | 32 | 9.0 | 0.415 | 0.0234 | 95 | 4.9 | |

| SWC225DH2 | 70 | 640 | 0.397 | 92 | |||||||||||||||

| SWC250DH1 | 250 | 63 | 31.5 | ≤15 | 100 | 795 | 218 | 150 | 168 | 140 | 8-19 | 25 | 6 | 40 | 12.5 | 0.900 | 0.0277 | 148 | 5.3 |

| SWC250DH2 | 70 | 735 | 0.885 | 136 | |||||||||||||||

| SWC285DH1 | 285 | 90 | 45 | ≤15 | 120 | 950 | 245 | 170 | 194 | 160 | 8-21 | 27 | 7 | 40 | 15.0 | 1.876 | 0.0510 | 229 | 6.3 |

| SWC285DH2 | 80 | 880 | 1.801 | 221 | |||||||||||||||

| SWC315DH1 | 315 | 125 | 63 | ≤15 | 130 | 1070 | 280 | 185 | 219 | 180 | 10-23 | 32 | 8 | 40 | 15.0 | 3.331 | 0.0795 | 346 | 8.0 |

| SWC315DH2 | 90 | 980 | 3.163 | 334 | |||||||||||||||

| SWC350DH1 | 350 | 180 | 90 | ≤15 | 140 | 1170 | 310 | 210 | 267 | 194 | 10-23 | 35 | 8 | 50 | 16.0 | 6.215 | 0..2219 | 508 | 15.0 |

| SWC350DH2 | 90 | 1070 | 5.824 | 485 | |||||||||||||||

| SWC390DH1 | 390 | 250 | 125 | ≤15 | 150 | 1300 | 345 | 235 | 267 | 215 | 10-25 | 40 | 8 | 70 | 18.0 | 11.125 | 0.2219 | 655 | |

| SWC390DH2 | 90 | 1200 | 10.763 | 600 | |||||||||||||||

* 1. Tf-under the alternation load the torque which permits according to the fatigue strength. * 2. Lmin-the least length after the cut. * 3. L-install length, which is according to the requirement

The SWC Universal Joint Coupling, often called the SWC Cardan Shaft Universal Joint Coupling, is a key component in heavy-duty industrial scenarios. It is indispensable for rolling mills, hoisting machinery, and various large-scale heavy machinery systems. As a high-torque universal joint coupling, it can effectively connect two transmission shafts with non-coincident axes, ensuring uninterrupted power transmission even under complex and harsh working conditions.

The core technical parameters of this coupling are as follows:

Gyration Diameter: φ58 - φ620

Nominal Torque: 0.15 - 1000 kN·m

Axis Fold Angle: ≤25°

In practical applications, it performs exceptionally well. For instance, during rolling mill operations, when a reliable heavy-duty universal joint coupling dedicated to rolling mills is needed, or in lifting and material handling equipment, when a durable SWC universal joint shaft coupling is required, this product is fully competent. Even under heavy loads, it can stably maintain the operational stability of the equipment.

The SWC universal joint coupling is designed using advanced engineering principles, delivering exceptional performance and longer service life in industrial environments. Its main structural features are as follows:

Reasonable and Safe Structure: Featuring an integrated fork head design, this industrial universal joint coupling reduces the risk of bolt loosening or breakage, increasing structural strength by 30%-50%. This design ensures safe and reliable operation, extends service life compared to traditional models, and prevents common failures in high-pressure scenarios such as heavy machinery universal joint coupling systems.

Enhanced Load-Bearing Capacity: The SWC heavy-duty universal joint coupling is specifically designed to bear heavy loads, making it essential in scenarios requiring excellent load management such as mining or construction machinery.

High Transmission Efficiency: With an efficiency of up to 98.6%, this efficient universal joint coupling for high-power transmission significantly reduces energy consumption and related costs, making it the first choice for energy-saving universal joint coupling solutions in high-power industrial transmission systems.

Stable Operation with Low Noise: This low-noise universal joint coupling operates stably with noise levels typically between 30-40 dB(A), ensuring quiet performance. It is ideal for noise-sensitive environments while maintaining high reliability.

Universal joint couplings, especially the SWC cardan shaft universal joint coupling, have become indispensable transmission components in industrial applications due to their outstanding advantages. They can meet core needs with their performance in fields such as heavy machinery, precision manufacturing, and energy transmission. Below is a detailed analysis of their key advantages:

1. Strong Torque Transmission and Excellent Misalignment Compensation

As a high-torque universal joint coupling, it can stably transmit high-power loads. Even in scenarios where shaft misalignment occurs frequently during rolling mill operations—such as axial offset caused by roller wear and temperature changes during steel rolling—this reliable heavy-duty universal joint coupling for rolling mill operations can handle it with ease. It can simultaneously compensate for angular, axial, and radial misalignments, with a maximum angular misalignment of up to 25 degrees. This excellent misalignment adaptability prevents transmission jams caused by shaft misalignment, ensures continuous and stable power delivery, significantly reduces the probability of mechanical failures under extreme working conditions, and guarantees the continuous operation of production lines.

2. High Durability and Longer Service Life

The design and material selection of SWC universal joint couplings are centered on "resisting heavy loads and withstanding harsh environments". The main body is made of high-strength alloy steel, combined with an integrated fork head structure, which fundamentally reduces common failure points such as bolt loosening and component breakage. Taking the durable SWC universal joint shaft coupling used in lifting and material handling equipment as an example, it can withstand the instantaneous impact load when lifting heavy objects and maintain stable performance in harsh environments such as dust and high temperatures. Compared with traditional split-structure couplings, this industrial universal joint coupling has an overall strength increased by 30%-50%, which not only reduces the frequency of daily maintenance but also extends the service life by 2-3 years. It is particularly suitable for the long-term high-load operation needs of heavy machinery universal joint coupling systems.

3. High Transmission Efficiency and Significant Energy-Saving Effect

Tests have shown that the transmission efficiency of the SWC heavy-duty universal joint coupling is as high as 98.6%, which has obvious advantages in high-power industrial transmission scenarios—such as blast furnace fans in steel plants and coal conveying systems in power plants. For equipment that requires continuous high-power transmission, matching with this efficient universal joint coupling for large power transmission can minimize power loss. For enterprises pursuing energy-saving universal joint coupling solutions, this high efficiency can be directly converted into cost advantages: taking a 1500kW industrial motor as an example, it can save more than 12,000 yuan in electricity costs per year, and can help enterprises reduce considerable operating costs in long-term use, while complying with the energy-saving and consumption-reduction trends in the industrial field.

4. Stable and Quiet Operation, Suitable for Multiple Scenarios

By optimizing the bearing fit accuracy and using lubricating grease with a low friction coefficient, the operating noise of this low-noise universal joint coupling is strictly controlled at 30-40 dB(A), which is equivalent to the ambient noise level of a daily office and fully complies with the noise emission standards of industrial sites. In noise-sensitive scenarios—such as production lines in food processing plants and conveying equipment for precision electronic components—it can not only ensure the stability and reliability of the transmission system but also avoid affecting the workshop environment or employees' operating experience due to noise. At the same time, the stable transmission characteristics can also reduce the wear of surrounding components caused by equipment vibration, further improving the operating stability and service life of the entire production system.

The SWC-DH Short Flex Welding Type Universal Coupling, often referred to as the SWC cardan shaft universal joint coupling, is mainly used in heavy machinery scenarios such as rolling mills and hoists. This type of equipment has extremely high requirements for structural compactness and flexibility—only by meeting these two points can efficient operation be achieved, and this coupling perfectly meets such needs. As a high-torque universal joint coupling, it can effectively connect two transmission shafts with non-coincident axes, ensuring seamless power transmission even in harsh industrial environments that require precise compensation for shaft system misalignment.

In practical applications, whether a reliable heavy-duty universal joint coupling for rolling mill operations is needed during rolling mill work, or a durable SWC universal joint shaft coupling is required in lifting and material handling equipment, this product can perform excellently—it can maintain stable equipment operation even under extreme loads. Its adaptability advantage is particularly prominent in compact equipment layouts where space is limited and a short flexible structure design is required.

This SWC-DH industrial universal joint coupling is built with advanced engineering technology and optimized for performance and service life specifically for industrial scenarios. Its core structural feature lies in its reasonable and safe design: the integrated fork head structure fundamentally eliminates the hidden dangers of bolt loosening or breakage, increasing the overall strength by 30%-50%. This design not only ensures the safety and reliability of operation but also extends the service life compared with traditional models, while avoiding common failure problems in high-stress application scenarios such as heavy machinery universal joint coupling systems.

In addition, its load-bearing capacity is enhanced through design to withstand greater weights, so this SWC heavy-duty universal joint coupling is very suitable for scenarios with strict requirements on load-bearing capacity, such as mining machinery and construction equipment. In terms of transmission efficiency, it reaches up to 98.6%. As an efficient universal joint coupling for large power transmission, it can significantly reduce energy consumption and electricity costs, making it a preferred product for energy-saving universal joint coupling solutions in the field of high-power industrial transmission.

Finally, this coupling features stable transmission, with operating noise usually controlled at 30-40 dB(A), making it a low-noise universal joint coupling. This characteristic allows it to operate quietly even in noise-sensitive industrial scenarios while maintaining high reliability at all times.

⭐⭐⭐⭐⭐ Wang Lei, Project Engineer, Guangdong Heavy Machinery Co., Ltd.

We’ve been using Raydafon’s SWC-DH Short Flex Welding Type Universal Coupling in our heavy machinery for a while now, and it’s been a pleasant surprise—especially when it comes to fitting into tight spots. Our equipment has pretty limited space for transmission parts, but this coupling’s compact design fits like a glove, no need to rearrange other components just to make it work.

What’s even better is that it doesn’t sacrifice performance for size. It still delivers strong, steady torque transmission—critical for our heavy-duty operations. We’ve run it continuously for weeks, and there’s been zero abnormal vibration; the whole system stays smooth. The welding quality is another highlight too—you can tell it’s solid just by looking at it, which gives us total confidence it’ll hold up to long-term heavy use. For a coupling that balances space-saving design and reliability, this one’s a winner.

⭐⭐⭐⭐⭐ Zhao Ming, Procurement Manager, Tianjin Steel Equipment Co., Ltd.

We recently ordered several SWC-DH couplings from Raydafon, and I have to say, the whole procurement process was a breeze—no headaches, no delays. From the moment we sent in the order, their team was responsive, and the delivery showed up right on the scheduled date, which is a big plus for keeping our production on track. The packaging was also top-notch: each coupling was wrapped securely, no dents or damage during shipping—just ready to unbox and install.

Our technical team handled the setup, and they mentioned right away how easy it was to mount. No complicated steps, no need to hunt for special tools—they got it fitted quickly, and it’s been running reliably ever since. When you factor in the reasonable price paired with this consistent performance, it’s clear this coupling offers great value. We’re already planning to keep it on our regular procurement list; it’s the kind of product that makes my job as a buyer easier.

⭐⭐⭐⭐⭐ Liu Hong, Maintenance Director, Shandong Industrial Group

As someone who oversees equipment maintenance, my biggest priority is cutting down on downtime and reducing the time my team spends on servicing parts. Raydafon’s SWC-DH coupling checks both those boxes perfectly. We use it in equipment that runs under heavy workloads daily, and it never slips or shifts—stays firmly in place, no loose connections. Even after months of use, there’s barely any sign of wear, which is a huge contrast to other couplings we’ve used before.

With those older couplings, we were always scheduling quick fixes or part replacements, which ate into production time and added up in costs. This one? We barely touch it—no frequent servicing, no unexpected breakdowns. It’s saved us so much time and money on maintenance, and it just keeps doing its job reliably. These days, it’s become a go-to component in our daily operations; I don’t have to worry about it failing, which lets me focus on other priorities. It’s exactly the kind of reliable part every maintenance team needs.

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Tel

+86-574-87168065

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Copyright © Raydafon Technology Group Co.,Limited All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |