QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Raydafon’s SWC-WD Short Without Flex Flange Type Universal Coupling is built to move torque efficiently in heavy machinery—think steel rolling mills, cranes, lifting equipment, all that heavy-duty gear. It’s got a compact, non-telescopic flange design, with gyration diameters ranging from 180mm to 1320mm. This short flange universal coupling can handle angular misalignments up to 15 degrees and torque as high as 16000 kN·m, so even in tight spaces where there’s not much room, it keeps power transferring reliably. We make it from high-strength 35CrMo steel, with a bearing structure that doesn’t need bolts—perfect for universal couplings for heavy machinery and non-telescopic universal couplings for industrial applications. It doesn’t require much upkeep and lasts forever, which is exactly what you need in tough setups.

Our manufacturing in China follows ISO 9001 standards, so the SWC-WD universal coupling holds up in harsh conditions. The cross shaft is chrome-plated to resist corrosion, adding to its toughness. Its rigid, welded flange design makes installation a breeze, especially in metallurgy and mining equipment where axial movement is pretty minimal. We can customize the size to fit your needs, so this durable short universal coupling works great as custom universal couplings for crane systems and other heavy-duty jobs. And the price is competitive too. Raydafon’s precise craftsmanship means less downtime and more reliable equipment—something industrial operators around the world can count on.

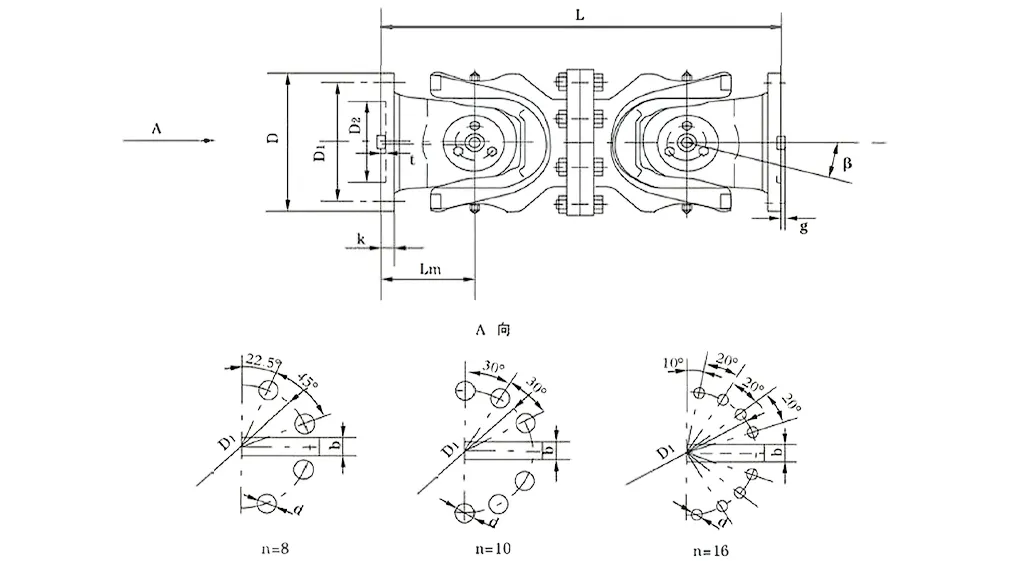

| No. | Gyration diameter D mm | Nominal torque Tn KN·m | Axes fold angle β (°) | Weary torque Tf KN·m | Size (mm) | Weight (kg) | |||||||||

| Lmin | D1 (js11) | D2 (H7) | Lm | n-d | k | t | b (h9) | g | Lmin | Increase 100mm | |||||

| SWC180WD | 180 | 12.5 | 6.3 | ≤25 | 440 | 155 | 105 | 110 | 8-17 | 17 | 5 | - | - | 0.145 | 52 |

| SWC225WD | 225 | 40 | 20 | ≤15 | 480 | 196 | 135 | 120 | 8-17 | 20 | 5 | 32 | 9.0 | 0.355 | 82 |

| SWC250WD | 250 | 63 | 31.5 | 560 | 218 | 150 | 140 | 8-19 | 25 | 6 | 40 | 12.5 | 0.831 | 127 | |

| SWC285WD | 285 | 90 | 45 | 640 | 245 | 170 | 160 | 8-21 | 27 | 7 | 40 | 15.0 | 1.715 | 189 | |

| SWC315WD | 315 | 125 | 63 | 720 | 280 | 185 | 180 | 10-23 | 32 | 8 | 40 | 15.0 | 2.820 | 270 | |

| SWC350WD | 350 | 180 | 90 | 776 | 310 | 210 | 194 | 10-23 | 35 | 8 | 50 | 16.0 | 4.791 | 370 | |

| SWC390WD | 390 | 250 | 125 | 860 | 345 | 235 | 215 | 10-25 | 40 | 8 | 70 | 18.0 | 8.229 | 524 | |

| SWC440WD | 440 | 355 | 180 | 1040 | 390 | 255 | 260 | 16-28 | 42 | 10 | 80 | 20.0 | 15.320 | 798 | |

| SWC490WD | 490 | 500 | 250 | 1080 | 435 | 275 | 270 | 16-31 | 47 | 12 | 90 | 22.5 | 25.740 | 1055 | |

| SWC550WD | 550 | 710 | 355 | 1220 | 492 | 320 | 305 | 16-31 | 50 | 12 | 100 | 22.5 | 46.780 | 1524 | |

| SWC620WD | 620 | 1000 | 500 | 1360 | 555 | 380 | 340 | 10-38 | 55 | 12 | 100 | 25.0 | 83.760 | 2120 | |

* 1. Tf-under the alternation load the torque which permits according to the fatigue strength.

Raydafon’s SWC universal joint coupling—usually called the SWC cardan shaft universal joint coupling—isn’t just a part; it’s a must-have in heavy-duty industrial fields, like rolling mills, hoisting equipment, and all sorts of tough heavy machinery setups. As a high-torque universal joint coupling, it does a solid job linking two transmission shafts that aren’t perfectly aligned, making sure power gets delivered smoothly even when the working conditions are really harsh.

Let’s talk about its core specs: gyration diameter ranges from φ58 to φ620, nominal torque goes from 0.15 to 1000 kN·m, and the axis fold angle is no more than 25°.

This coupling works best in specific spots—like when you need a reliable heavy-duty universal joint coupling for rolling mill operations, or a durable SWC universal joint shaft coupling in lifting and material handling equipment. In these cases, it shows off its strength: even under big stresses, it keeps operations steady, no mess or breakdowns.

Raydafon’s SWC universal joint coupling isn’t just thrown together—it’s built with smart, up-to-date engineering to work great and hold up long in industrial use. Let’s walk through what makes its structure stand out.

First, it has a reasonable and safe configuration: we used an integrated fork head design for this industrial universal joint coupling, which cuts down on risks like bolts coming loose or breaking. That tweak alone makes it 30%-50% sturdier overall, so it runs safely and consistently. Compared to regular couplings, it lasts way longer, and it avoids common problems in high-tension spots—like the heavy machinery universal joint coupling systems you see in tough jobs.

Then there’s its enhanced load-bearing capacity: this SWC heavy-duty universal joint coupling is made to handle big weights, so it’s a must-have in places that need top-notch load handling, like mining gear or construction machines.

It also hits high transmission efficiency—up to 98.6%. As an efficient universal joint coupling for large power transmission, it slashes energy use and the costs that come with it. That’s why it’s a top pick for energy-saving universal joint coupling solutions in high-power industrial transmission setups.

And it runs smooth with low noise: transmission stays steady, and noise usually hovers between 30-40 dB(A). This low-noise universal joint coupling keeps operations quiet, which is perfect for industrial spots where noise is a problem—all while keeping reliability at a high level.

⭐⭐⭐⭐⭐ Zhang Wei, Chief Engineer, Henan Mining Equipment Co., Ltd.

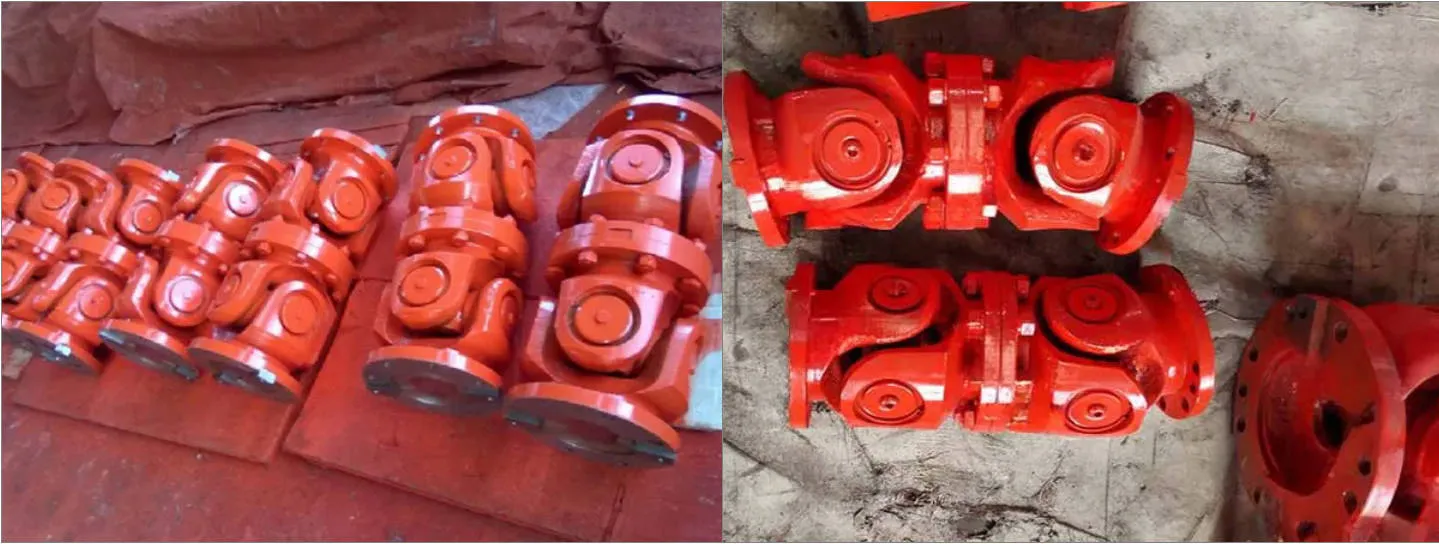

We’ve been putting Raydafon’s SWC-WD Short Without Flex Flange Type Universal Coupling on our mining machinery, and it’s been a perfect fit. Its compact design is just what we need for tight spaces where there’s not much room to spare, and the build is tough enough to keep operations steady. Even when it’s running nonstop under heavy-duty conditions, this coupling never lets us down—no failures at all. Our maintenance team loves that it barely needs checking in on, which means we can keep production moving smoothly without extra hassle.

⭐⭐⭐⭐⭐ Michael Brown, Operations Manager, Texas Steel Works, USA

Our Texas workshop ordered the SWC-WD Short Without Flex Flange Type Universal Coupling from Raydafon, and honestly, the quality has blown us away. The couplings are machined really well, installing them is a cinch, and they hold up reliably even when under load. What stuck out most to me? How well it balances price and performance—you don’t often find that sweet spot. Finding a supplier that consistently delivers this level of quality isn’t easy, but Raydafon has absolutely proven they’re a trustworthy partner for us.

⭐⭐⭐⭐⭐ Anna Müller, Maintenance Supervisor, Berlin Industrial Solutions, Germany

We put Raydafon’s SWC-WD Short Without Flex Flange Type Universal Coupling on our Berlin equipment line, and the results have been great. The product itself feels rock-solid, the welding is precise—no shoddy work here—and so far, it’s held up really well, showing top-notch durability. Compared to some other brands we’ve used here in Europe, this coupling is way more reliable, and the price is way more competitive too. If other companies are looking for dependable universal couplings, I’d absolutely recommend Raydafon.

Raydafon’s SWC-WD Short Without Flex Flange Type Universal Coupling—often called the SWC cardan shaft universal joint coupling—is built for tight industrial spots, where space is limited and you need a fixed-length design (no telescopic extension). As a high-torque universal joint coupling, it moves torque efficiently between shafts that aren’t aligned, handling angular deviations up to 25 degrees, and it stays reliable even in heavy-duty environments.

Let’s talk about its key features: It has a compact and rigid structure—this short, non-flexible flange setup makes it a reliable heavy-duty universal joint coupling for rolling mill operations, giving extra stability in setups where axial movement is minimal. That’s why it works so well for fixed-distance connections in tough machinery. Then there’s its high load-bearing capacity: we use tough materials like cast iron or alloy steel to make it, so it’s a durable SWC universal joint shaft coupling in lifting and material handling equipment. It holds big weights and transmits more torque than other couplings of the same diameter, which makes it perfect for heavy loads in mining or construction gear.

This industrial universal joint coupling also compensates for misalignment really well—whether it’s angular, parallel, or axial misalignment, it doesn’t mess with rotational speed or torque transfer. That means smooth operation in heavy machinery universal joint coupling systems. And it’s efficient at power transmission: hitting up to 98.6% efficiency, this SWC heavy-duty universal joint coupling keeps energy loss low, making it an efficient universal joint coupling for large power transmission in high-power industrial setups.

Plus, it’s designed to save energy and run quiet—if you need energy-saving universal joint coupling solutions, this is a top pick, cutting operational costs. And it keeps noise between 30-40 dB(A), so this low-noise universal joint coupling fits right in industrial spots where noise is a concern.

This coupling really shines in specific scenarios—like when you need a reliable heavy-duty universal joint coupling for rolling mill operations, or a durable SWC universal joint shaft coupling in lifting and material handling equipment. In these cases, even with extreme loads and limited space, it keeps operations stable, no hiccups.

When it comes to industrial universal joint coupling applications, our SWC-WD variant stands out with smart engineering that makes it perform better and last longer. Let’s talk about its key structure: it has a reasonable, safe setup with an integrated fork head design—this gets rid of problems like bolts coming loose or breaking, boosting overall strength by 30%-50%. That means it runs safely and reliably, lasts longer than old-style models, and avoids common breakdowns in high-stress places, like heavy machinery universal joint coupling systems.

Plus, it can handle way more load—we built it to support heavier weights, so this SWC heavy-duty universal joint coupling is perfect for places that need tough load handling, like mining or construction equipment. It also moves power super efficiently, hitting up to 98.6% transmission efficiency. As an efficient universal joint coupling for large power transmission, it cuts down energy use and the costs that come with it, making it a top pick for energy-saving universal joint coupling solutions in high-power industrial transmission setups.

And it runs smooth with barely any noise—transmission stays steady, and noise usually stays between 30-40 dB(A). This low-noise universal joint coupling keeps operations quiet, which is perfect for industrial spots where noise is a problem, all while keeping reliability at a high level.

Raydafon isn’t just another name in transmission parts—we’re a leading manufacturer and supplier of high-performance transmission components and industrial machinery solutions, and we’ve got a sharp focus on products like the SWC cardan shaft universal joint coupling. We started up to keep up with what global industries need as they evolve, and over time, we’ve built out a full lineup: gearboxes, drive shafts, hydraulic cylinders, pulleys, precision machine tools—all made to boost how well agricultural and heavy-duty sectors run. We’re big on innovation, which is why we can deliver reliable heavy-duty universal joint coupling for rolling mill operations that fit right into even the most complex systems without a hitch.

Our facilities are top-notch, too—we’ve got CNC workshops, grinding and heat treatment gear, and advanced 3D measurement systems. We stick to strict quality standards like ISO9001/TS16949, and that setup lets us make high-torque universal joint coupling solutions that move torque great and handle misalignment like a pro. Take our durable SWC universal joint shaft coupling in lifting and material handling equipment, for example—it’s built for places that need tough load-bearing power. And our industrial universal joint coupling line? It covers all kinds of uses where precision and sturdiness matter most.

Eighty percent of what we make gets exported—sent to places like the US, Germany, Japan, Italy, Malaysia, Australia, and the Middle East. We’ve got strong networks in China, South Korea, the UK, Singapore, the US, and Spain too, so we’re solid globally. That reach lets us offer customized SWC heavy-duty universal joint coupling options—tailored exactly to what clients need, like in heavy machinery universal joint coupling systems where staying stable under extreme loads is non-negotiable.

We care about sustainability and making solutions that put customers first. That’s why we develop energy-saving universal joint coupling solutions that hit up to 98.6% transmission efficiency—cutting energy use in high-power setups. Whether you need an efficient universal joint coupling for large power transmission or a low-noise universal joint coupling for industrial spots where noise is a problem, our products come with full after-sales service. That’s how we’ve become a trusted partner in the transmission industry—we don’t just sell parts, we back them up.

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Tel

+86-574-87168065

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Copyright © Raydafon Technology Group Co.,Limited All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |