QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

The SWC-CH Long Flex Welding Type Universal Coupling from Raydafon is a heavy-duty universal coupling specifically engineered for power transmission scenarios involving misaligned shafts in heavy machinery, with exceptional suitability for core equipment such as rolling mills and industrial drive systems. These types of equipment are prone to shaft misalignment due to installation deviations or operational vibrations during long-term high-load operation, and this industrial universal shaft coupling precisely addresses this pain point.

As a high-performance long flex universal coupling, it can easily compensate for angular misalignment of up to 25 degrees while also accommodating a certain degree of radial and axial misalignment, ensuring stable and uninterrupted power transmission. It is constructed from high-strength 35CrMo alloy steel, which undergoes quenching and tempering treatment as well as precision machining. This not only endows it with excellent fatigue resistance and wear resistance but also enables it to maintain long-term durability under harsh working conditions such as high temperatures and heavy dust, fully meeting the high-strength requirements of heavy machinery for transmission components. Undoubtedly, it is a true example of universal couplings for heavy machinery.

Furthermore, the welded structure of this universal coupling is designed based on professional mechanical principles, featuring full and evenly strong welds. This effectively enhances torque transmission efficiency and prevents power loss or equipment failures caused by loose connections. Meanwhile, it is compatible with flexible shaft connection requirements in various industrial scenarios, making it a high-performance option among flexible shaft couplings for industrial applications.

Notably, this durable universal coupling is manufactured at Raydafon's ISO 9001-certified factory in China. From raw material procurement to finished product delivery, strict quality control systems are followed to ensure each product complies with international standards. To meet the personalized needs of different customers, the factory also offers customization services, such as adjusting the coupling's length and flange specifications. Additionally, the overall pricing is market-competitive, allowing enterprises to effectively control procurement costs while ensuring the stability of equipment transmission.

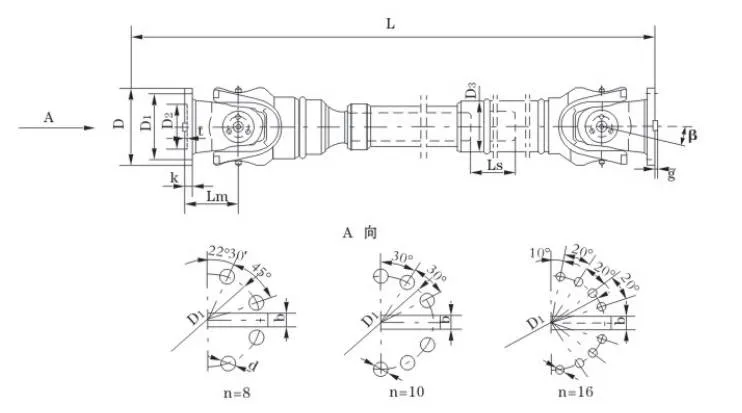

| No. | Gyration diameter D mm | Nominal torque Tn KN·m | Axes fold angle β (°) | Weary torque Tf KN·m | Flex quantity Ls mm | Size (mm) | Rotating inertia kg.m2 | Weight (kg) | |||||||||||

| Lmin | D1 (js11) | D2 (H7) | D3 | Lm | n-d | k | t | b (h9) | g | Lmin | Increase 100mm | Lmin | Increase 100mm | ||||||

| SWC180CH1 | 180 | 12.5 | ≤25 | 6.3 | 200 | 925 | 155 | 105 | 114 | 110 | 8-17 | 17 | 5 | - | - | 0.181 | 0.0070 | 74 | 2.8 |

| SWC180CH2 | 700 | 1425 | 0.216 | 104 | |||||||||||||||

| SWC225CH1 | 225 | 40 | ≤15 | 20 | 220 | 1020 | 196 | 135 | 152 | 120 | 20 | 32 | 9 | 0.561 | 0.0234 | 132 | 4.9 | ||

| SWC225CH2 | 700 | 1500 | 0.674 | 182 | |||||||||||||||

| SWC250CH1 | 250 | 63 | 31.5 | 300 | 1215 | 218 | 150 | 168 | 140 | 8-19 | 25 | 6 | 40 | 12.5 | 1.016 | 0.0277 | 190 | 5.3 | |

| SWC250CH2 | 700 | 1615 | 1.127 | 235 | |||||||||||||||

| SWC285CH1 | 285 | 90 | 45 | 400 | 1475 | 245 | 170 | 194 | 160 | 8-21 | 27 | 7 | 15 | 2.156 | 0.0510 | 300 | 6.3 | ||

| SWC285CH2 | 800 | 1875 | 2.360 | 358 | |||||||||||||||

| SWC315CH1 | 315 | 125 | 63 | 400 | 1600 | 280 | 185 | 219 | 180 | 10-23 | 32 | 8 | 3.812 | 0.0795 | 434 | 8.0 | |||

| SWC315CH2 | 800 | 2000 | 4.150 | 514 | |||||||||||||||

| SWC350CH1 | 350 | 180 | 90 | 400 | 1715 | 310 | 210 | 267 | 194 | 35 | 50 | 16 | 7.663 | 0.2219 | 672 | 15.0 | |||

| SWC350CH2 | 800 | 2115 | 8.551 | 823 | |||||||||||||||

| SWC390CH1 | 390 | 250 | 125 | 400 | 1845 | 345 | 235 | 267 | 215 | 10-25 | 40 | 70 | 18 | 12.730 | 817 | ||||

| SWC390CH2 | 800 | 2245 | 13.617 | 964 | |||||||||||||||

| SWC440CH1 | 440 | 355 | 180 | 400 | 2110 | 390 | 255 | 325 | 260 | 16-28 | 42 | 10 | 80 | 20 | 22.540 | 0.4744 | 1312 | 21.7 | |

| SWC440CH2 | 800 | 2510 | 24.430 | 1537 | |||||||||||||||

| SWC490CH1 | 490 | 500 | 250 | 400 | 2220 | 435 | 275 | 325 | 270 | 16-31 | 47 | 12 | 90 | 22.5 | 33.970 | 1554 | |||

| SWC490CH2 | 800 | 2620 | 35.870 | 1770 | |||||||||||||||

| SWC550CH1 | 550 | 710 | 355 | 500 | 2585 | 492 | 320 | 426 | 305 | 16-31 | 50 | 100 | 72.790 | 1.3570 | 2585 | 34.0 | |||

| SWC550CH2 | 1000 | 3085 | 79.570 | 3045 | |||||||||||||||

* 2. Lmin-the least length after the cut.

* 3. L-install length, which is according to the requirement.

The SWC Universal Joint Coupling – often called the SWC Cardan Shaft Universal Joint Coupling – is a heavy-duty industrial universal coupling built specifically for tough industrial use. It works best with equipment that needs reliable transmission and strong load-bearing, like rolling mills in steel plants, hoisting machines for construction, and large heavy-duty systems in mining or shipping. These machines usually run under high loads and torque, and this SWC Cardan Universal Joint Coupling fits their transmission needs perfectly.

As a high-torque universal joint coupling, it connects two misaligned transmission shafts effectively. Even when equipment runs under heavy loads for a long time, it keeps power flowing steadily without breaks. This stops transmission loss or equipment breakdowns that happen when shafts are out of line. For rolling mills, it’s a go-to heavy-duty universal joint coupling for rolling mill operations – it handles the shifting shaft positions during rolling, so production stays accurate and efficient. For lifting and material-handling gear, it acts as a durable SWC universal joint shaft coupling, taking the sudden impact torque when lifting heavy things and making operations safer.

This SWC Universal Joint Coupling’s key technical specs meet industrial standards, and they’re also tweaked for real-world use:

Gyration Diameter: φ58 - φ620mm. It covers transmission needs from small heavy-duty machines to big industrial units, and you can adjust it to match the size of your equipment’s transmission shaft.Nominal Torque: 0.15 - 1000 kN·m. The wide torque range works for both light heavy-duty machinery and extra-large equipment that needs high-torque transmission.Axis Fold Angle: ≤25°. It’s great at fixing misalignment – it soaks up shaft shifts caused by wrong installation, vibrations, or load changes when equipment runs. This helps keep the transmission system stable and long-lasting.

When you’re looking for someone to trust with mechanical components—especially things like the SWC-BH Standard Flex Welding Type Universal Coupling—Raydafon isn’t just another option. We’re a manufacturer that lives and breathes quality, and that shows in every part we make.

First off, quality isn’t an afterthought for us. We use top-tier engineering techniques and put every single universal joint coupling—whether it’s a high-torque one for heavy machinery or an industrial-grade model for factory setups—through strict checks. Every part meets ISO 9001 standards, and we test them hard: extreme loads, rough conditions, whatever your industry throws at it. The goal? No unexpected failures, less risk for your operations, and a coupling that keeps your systems running smoothly.

Then there’s the customization. Let’s be real—no two jobs are the same. Maybe you need a drive shaft universal coupling with specific dimensions, or a marine propulsion universal coupling made from corrosion-resistant material, or even a renewable energy universal coupling tuned for just the right torque. We don’t make you fit a “one-size-fits-all” part. Tell us what you need, and we’ll tailor it to slot right into your existing setup—whether that’s in automotive, marine, or solar/wind systems.

And we get that cost matters, too. You shouldn’t have to choose between a good coupling and a fair price. We’ve optimized our supply chain and scaled our production so we can offer competitive rates on even specialized parts—like that marine propulsion universal coupling or high-torque industrial model—without cutting corners on quality. It’s about giving you value that lasts, not just a cheap part that fails fast.

Our team doesn’t disappear once you hit “order,” either. From the first call—when you’re trying to figure out which universal joint coupling works best for your renewable energy gear or factory line—to after-sales support if you have questions, we’re here. We’ve got years of industry know-how, so we can guide you to the right choice, help you avoid downtime, and make sure your coupling does exactly what you need it to.

At Raydafon, we’re not just selling parts—we’re building partnerships. We want to be the team you trust to keep your operations moving forward, with universal joint solutions that work as hard as you do. If you’ve got specific needs, reach out to our specialists today—let’s talk about how we can help.

The SWC-CH long flex welding type universal joint coupling isn’t just a part—it’s a flagship from HZPT, under the EVER-POWER Group, built specifically to move power reliably when shafts don’t line up. If you need a high-torque universal joint coupling that can handle heavy-duty work, this is the one: it connects two shafts with mismatched axes, no hiccups, even when the pressure’s on. You’ll find it hard at work across the USA—think rolling mills, hoisting gear, and all sorts of industrial heavy machinery—managing angular misalignments up to 25° without dropping efficiency.

Take American industries, for example. In the Midwest’s steel plants, where machines run hot and heavy, or Texas’s mining sites, where loads are relentless, this SWC-CH industrial universal joint coupling keeps torque moving steady. Let’s look at Chicago’s rolling mills: that’s where the SWC-CH heavy-duty universal joint coupling for rolling mills really shines. It makes up for shaft shifts caused by heat expansion or everyday wear, cutting downtime by as much as 40%. And its long flex design? Perfect for setups where shafts are far apart—over 30 meters, like the crane systems in Florida’s ports or ship drives that need extra axial give.

It’s not just about connecting shafts, either. Over in New York’s construction sites, this efficient universal joint coupling for large power transmission hits 98.6% efficiency—so less energy gets wasted, and electricity bills stay lower, even when machines are cranking at full power. And it’s quiet: 30-40dB(A), which checks all the boxes for USA workplace safety rules. That’s a big win for noise-sensitive spots, like the paper-making machines in California’s factories. Whether it’s crushers in Texas’s oil fields or straighteners in Pennsylvania’s manufacturing plants, this SWC-CH low-noise universal joint coupling keeps performing—no more of the bolt-loosening headaches that plague older couplings.

From metallurgy to petroleum, this energy-saving universal joint coupling fits over 80 different uses, each tuned to work with regional needs. Take the Rocky Mountains’ engineering transport: the welding-type build cranks up strength by 30% to 50%, handling heavy loads without breaking a sweat. For USA heavy machinery pros who want reliability and long life, the SWC-CH is the go-to pick—no exceptions.

|

|

|

|

⭐⭐⭐⭐⭐ Zhang Wei, Engineer, Jiangsu Machinery Co., Ltd.

In my line of work as a mechanical engineer, transmission system stability and durability are always top of mind—they’re make-or-break for our equipment’s performance. We recently integrated Raydafon’s SWC-CH Long Flex Welding Type Universal Coupling into our setup, and the difference has been clear. Even when we’re running at high torque—something that usually causes vibrations or alignment hiccups with other couplings—this one operates smoothly, no shaky feedback or misalignment issues at all.

What really impressed me is the welding precision. Once we got it installed, there was zero need for extra tweaks or readjustments—we just bolted it in and it was good to go. That cut down our commissioning time by a solid chunk, which meant we could get the line up and running faster. And the flexibility? It handles both axial and angular misalignments like a pro, keeping our equipment humming at peak efficiency. For long-term, reliable use, this coupling checks every box we need.

⭐⭐⭐⭐⭐ Li Na, Purchasing Manager, Shanghai Power Equipment Co., Ltd.

As a purchasing manager, I can’t just focus on how well a product works—I also need to know it’ll arrive on time, in good shape, and that the service behind it is solid. Raydafon’s SWC-CH coupling nailed all three, and then some. From the minute we placed the order to when it showed up at our warehouse, the whole process was smooth and efficient. The packaging was thorough too—no dents, no scratches, just the coupling in perfect condition, ready to use.

Price-wise, it’s more than fair—great quality without the inflated cost, exactly what we look for in a “high-value, high-performance” product. But don’t just take my word for it: our production team loved it too. They said installation was straightforward (no complicated instructions or special tools needed), and once it was in, it ran steady and reliable. That’s translated to lower maintenance costs for us—no unexpected fixes or replacements. As a China-based manufacturer with real professionalism, Raydafon’s earned our trust. We’ll absolutely be coming back for future orders.

⭐⭐⭐⭐⭐ Chen Hao, Maintenance Supervisor, Beijing Industrial Group

My job as maintenance supervisor means I’m always watching for products that last—durability and long service life aren’t nice-to-haves, they’re necessities, especially on our 24/7 production line. Raydafon’s SWC-CH Long Flex Welding Type Universal Coupling has held up beautifully under that nonstop pressure. Even when the line’s running at full load, it stays stable—no loosening, no weird wear patterns, just consistent performance.

The build quality is standout: the structure feels solid, and the welding is strong, which I know is why it’s so reliable long-term. We’ve barely had to touch it for maintenance—no regular tune-ups or part swaps—and that’s been a game-changer. Less maintenance means less downtime, and fewer repair risks, which keeps our line moving and our costs down.

We’ve used other universal couplings before, but this one outperforms them all in both reliability and practicality. Picking Raydafon didn’t just make my team’s job easier—it boosted our production line efficiency and saved us a lot in maintenance expenses. It’s a no-brainer for anyone who needs a coupling they can count on.

When it comes to universal joint couplings, Raydafon isn’t just another name in the crowd. We’ve spent decades honing our craft in transmission components, and that experience shows in every part we make—especially our SWC-CH industrial universal joint coupling. What really sets this coupling apart? Our proprietary welding technology. It eliminates those weak spots you often get with standard models, the kind that wear out fast or fail under pressure. The result? A longer service life, so you’re not replacing parts every few months.

We’re based in China, but our reach extends far—particularly to clients across the USA. And we don’t believe in one-size-fits-all. Need something specific? No problem. Take Florida’s shipyards, for example, where saltwater and moisture eat away at regular materials. We’ll customize your coupling with stainless steel to stand up to that corrosion. Or if you’re in heavy industries like steel or mining, our SWC heavy-duty universal joint coupling is built with extra load-bearing muscle to handle those extreme demands.

Price matters, too—and we’ve worked hard to keep ours competitive without skimping on quality. But it’s not just about cost. When you need a prototype fast to test in your setup, we turn them around in 1-3 weeks. No waiting months to get your project moving. That speed, paired with our commitment to durability, is why so many USA businesses keep coming back.

Our service doesn’t end when you hit “order,” either. We back every coupling with 24/7 technical support—so if you run into a problem at 2 a.m. in Texas, there’s someone here to help. Every part comes with a 1-year warranty, and we even send experts on-site to guide installation for USA customers. No figuring it out alone; we’re with you from start to finish.

It’s not just talk—major players in USA steel and mining industries trust us to keep their operations running. And we’ve earned that trust by consistently delivering parts that meet the tough standards of both European and American markets. When you choose Raydafon, you’re not just getting a coupling—you’re getting a partner that understands how important it is to keep your machinery moving, with as little downtime as possible. That’s the difference experience, customization, and commitment make.

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Tel

+86-574-87168065

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Copyright © Raydafon Technology Group Co.,Limited All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |