QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

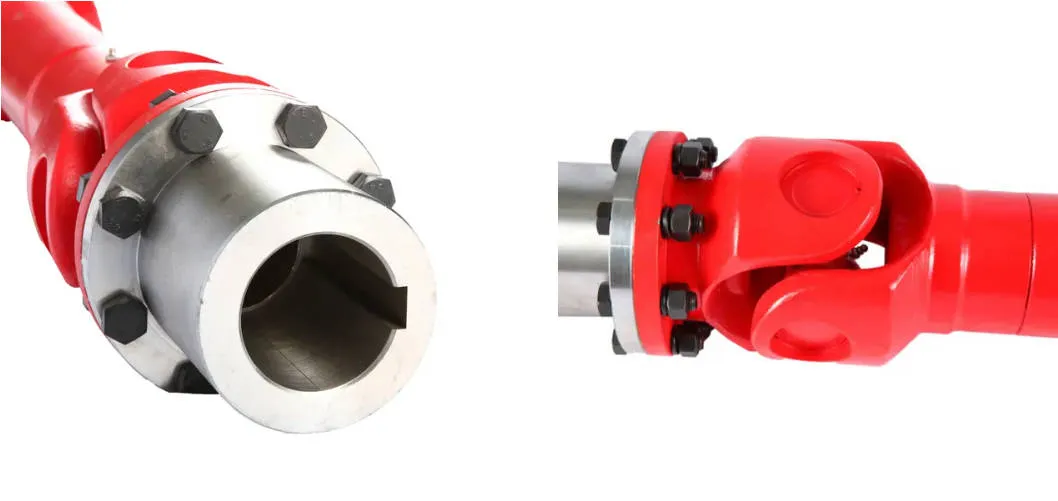

Raydafon’s SWC-BF Standard Flex Flange Type Universal Coupling is built to move torque reliably in heavy machinery—think rolling mills, paper-making equipment, industrial drives, all the setups that need tough performance. It has a flexible flange design, with gyration diameters ranging from 180mm to 620mm, and this standard flex universal coupling handles angular misalignments up to 15 degrees plus torque as high as 1250 kN·m. Even in demanding work environments, it keeps running steady, no drop-offs. We make it with high-strength 35CrMo steel and precision needle bearings, so it’s perfect as universal couplings for industrial machinery and flex flange couplings for heavy equipment—moves power strongly, and you barely notice any vibration.

Our manufacturing in China follows ISO 9001 standards, so the SWC-BF universal coupling lasts long and resists corrosion—all thanks to its chrome-plated cross shaft. The flange connection makes installation easy, which is a big help in fields like metallurgy, mining, and shipbuilding—places where you need moderate axial flexibility. We can customize its size and torque ratings too, so this durable flex universal coupling works great as custom universal couplings for rolling mills and other industrial needs. And the price is competitive, no overcharging. Raydafon’s know-how means you’ll spend less time on maintenance, and your equipment will stay more reliable—something operators around the world can count on.

| No. | Gyration diameter D mm | Nominal torque Tn KN·m | Axes fold angle β (°) | Weary torque Tf KN·m | Flex quantity Ls mm | Size (mm) | Rotating inertia kg.m2 | Weight (kg) | |||||||||||

| Lmin | D1 (js11) | D2 (H7) | D3 | Lm | n-d | k | t | b (h9) | g | Lmin | Increase 100mm | Lmin | Increase 100mm | ||||||

| SWC180BF | 180 | 12.5 | 6.3 | ≤25 | 100 | 810 | 155 | 105 | 114 | 110 | 8-17 | 17 | 5 | -1.455 | - | 0.27 | 0.0070 | 80 | 2.8 |

| SWC225BF | 225 | 40 | 20 | ≤15 | 140 | 920 | 196 | 135 | 152 | 120 | 8-17 | 20 | 5 | 32 | 9 | 0.79 | 0.0234 | 138 | 4.9 |

| SWC250BF | 250 | 63 | 31.5 | 1035 | 218 | 150 | 168 | 140 | 8-19 | 25 | 6 | 40 | 12.5 | 1.46 | 0.0277 | 196 | 5.3 | ||

| SWC285BF | 285 | 90 | 45 | 1190 | 245 | 170 | 194 | 160 | 8-21 | 27 | 7 | 40 | 15 | 2.87 | 0.0510 | 295 | 6.3 | ||

| SWC315BF | 315 | 125 | 63 | 1315 | 280 | 185 | 219 | 180 | 10-23 | 32 | 8 | 40 | 15 | 5.09 | 0.0795 | 428 | 8.0 | ||

| SWC350BF | 350 | 180 | 90 | 150 | 1410 | 310 | 210 | 267 | 194 | 10-23 | 35 | 8 | 50 | 16 | 9.20 | 0.2219 | 632 | 15.0 | |

| SWC390BF | 390 | 250 | 125 | 170 | 1590 | 345 | 235 | 267 | 215 | 10-25 | 40 | 8 | 70 | 18 | 16.62 | 0.2219 | 817 | 15.0 | |

| SWC440BF | 440 | 355 | 180 | 190 | 1875 | 390 | 255 | 325 | 260 | 16-28 | 42 | 10 | 80 | 20 | 28.24 | 0.4744 | 1290 | 21.7 | |

| SWC490BF | 490 | 500 | 250 | 190 | 1985 | 435 | 275 | 325 | 270 | 16-31 | 47 | 12 | 90 | 22.5 | 46.33 | 0.4744 | 1631 | 21.7 | |

| SWC550BF | 550 | 710 | 355 | 240 | 2300 | 492 | 320 | 426 | 305 | 16-31 | 50 | 12 | 100 | 22.5 | 86.98 | 1.3570 | 2567 | 34.0 | |

| SWC620BF | 620 | 1000 | 500 | 240 | 2500 | 555 | 380 | 426 | 340 | 10-38 | 55 | 12 | 100 | 25 | 147.50 | 1.3570 | 3267 | 34.0 | |

Universal couplings—also called universal joint couplings—are mechanical parts that move torque and rotational motion between two shafts that might not line up perfectly. They handle angular, axial, and radial misalignments, all while keeping power transfer efficient in different industrial uses. At Raydafon, our SWC cardan shaft universal joint coupling series is a prime example of top-notch engineering here, offering high-torque universal joint coupling solutions made just for heavy-duty spots like rolling mills and hoisting machinery.

Let’s break down the main types of universal joint couplings:

First up is the Single Universal Joint. It has one cross-shaped pivot connecting two yokes, letting shafts have angular misalignment up to 45 degrees. It works well for setups with moderate offsets, though it might cause velocity changes. Raydafon’s reliable heavy-duty universal joint coupling for rolling mill operations often uses single joint designs in compact builds, so it holds up great even under heavy loads.

Then there’s the Double Universal Joint. It has two single joints linked together, which handles bigger misalignments and keeps transmission velocity almost constant—perfect for tricky shaft setups. When you need a durable SWC universal joint shaft coupling in lifting and material handling equipment, Raydafon’s double joint models boost stability and cut down vibrations in high-stress industrial universal joint coupling systems.

Next is the Telescopic or Expandable Universal Joint. It has splines or sliding parts that let you adjust the length while also compensating for misalignment, which works for axial movements in dynamic setups. Raydafon’s SWC heavy-duty universal joint coupling includes telescopic options—they act as an efficient universal joint coupling for large power transmission in places like mines or construction sites, where you need flexibility in shaft length.

There are also Solid, Bored, or Splined Hub Types. These differ by how they connect: solid hubs have no holes, bored hubs have round, hex, or square openings, and splined hubs have grooves for a tight fit. For energy-saving universal joint coupling solutions, Raydafon offers splined designs in our low-noise universal joint coupling lineup—they optimize torque delivery and keep noise down to 30-40 dB(A) in sensitive industrial spots.

Raydafon’s universal joint couplings, including the SWC series, are made with integrated fork head designs—no more bolt-related issues, which boosts strength by 30%-50% and hits transmission efficiencies up to 98.6%. These features make our products a top choice for professionals who need customized, high-performance solutions.

Universal couplings—take Raydafon’s SWC cardan shaft universal joint coupling as a prime example—bring big benefits to industrial transmission systems. They move torque effectively between shafts that aren’t aligned, handling all kinds of deviations, and they’re a must for keeping operations running smoothly in tough environments—like the ones that need high-torque universal joint coupling solutions.

Let’s dive into their main advantages: First, they’re great at compensating for misalignment. Universal couplings handle angular, axial, and radial misalignments up to 25 degrees, which makes them a reliable heavy-duty universal joint coupling for rolling mill operations. They do this without adding too much mechanical stress or vibration, so your machinery stays protected.

Then there’s their tough durability and long service life. We build these couplings with integrated fork head designs and high-strength materials, which cuts down on risks like bolts coming loose or breaking—boosting structural integrity by 30%-50%. That’s why the durable SWC universal joint shaft coupling in lifting and material handling equipment works so well for long stretches in harsh conditions; it outlasts traditional models by a long shot.

They also have top-notch load-bearing and torque capacity. Engineered to hold heavy weights and transmit nominal torques from 0.15 to 1000 kN·m, the industrial universal joint coupling shines in heavy machinery universal joint coupling systems. In these setups, consistent performance under extreme loads is make-or-break, and this coupling delivers every time.

When it comes to power transmission efficiency, they’re hard to beat. Hitting up to 98.6% efficiency, the SWC heavy-duty universal joint coupling keeps energy loss low. That makes it an efficient universal joint coupling for large power transmission in high-power industrial applications, and over time, that efficiency adds up to real cost savings.

Last but not least, they save energy and run quiet. As energy-saving universal joint coupling solutions, they cut down on electricity use, and they operate at just 30-40 dB(A). This low-noise universal joint coupling is perfect for industrial spots where noise is a concern—you get all the reliability you need without the loud operation.

Universal couplings—most folks call ’em universal joint couplings—work on a simple but effective mechanical idea: they move torque and rotational motion between two shafts that don’t line up perfectly, handling angular, axial, and radial misalignments without skipping a beat. Take Raydafon’s SWC cardan shaft universal joint coupling, for example—it’s a great showcase of this principle. It uses a cross-shaped pivot (we often call it a spider) to connect the yokes on each shaft, so power transfers smoothly even in busy industrial setups.

The heart of how it works is that cross pivot: it lets the yokes rotate independently, which makes up for shaft tilts up to 25 degrees while keeping torque delivery consistent. This high-torque universal joint coupling also keeps rotational speed changes to a minimum—especially when it’s a double joint design—so it’s perfect for jobs that need a reliable heavy-duty universal joint coupling for rolling mill operations. And with Raydafon’s SWC series, we added an integrated fork head design to make this mechanism even better: it gets rid of problems like bolts coming loose, boosts structural strength by 30%-50%, and helps it last longer in high-stress spots.

This principle also supports great load-bearing capacity. The coupling handles nominal torques from 0.15 to 1000 kN·m, with gyration diameters between φ58 and φ620—that’s why the durable SWC universal joint shaft coupling in lifting and material handling equipment is such a solid pick for tough operations. Plus, the industrial universal joint coupling hits up to 98.6% transmission efficiency, cutting down on energy use in heavy machinery universal joint coupling systems.

What’s more, Raydafon’s SWC heavy-duty universal joint coupling has features that match the principle’s focus on smooth operation: it keeps transmission steady, and noise stays between 30-40 dB(A). That makes it an efficient universal joint coupling for large power transmission, and a top energy-saving universal joint coupling solution for high-power industrial setups. All in all, this low-noise universal joint coupling keeps things quiet, so it works great in places where noise is a concern—without sacrificing reliability.

⭐⭐⭐⭐⭐ Li Jun, Senior Engineer, Jiangsu Power Equipment Co., Ltd.

We’ve been using Raydafon’s SWC-BF Standard Flex Flange Type Universal Coupling for a few months now, and it’s been performing great. What stands out most is the flexibility of this coupling—it’s made our machinery way more reliable, especially when it comes to compensating for shaft misalignment. Installing it was a smooth process, no tricky steps, and the weld quality looks solid too—definitely gives us peace of mind that it’ll last. For the price, it’s a really good value, and if you’re in the heavy machinery industry, I’d absolutely recommend this flexible flange universal coupling.

⭐⭐⭐⭐⭐ John Davis, Mechanical Engineer, Manchester Engineering Ltd., UK

At our Manchester facility, we swapped out an old coupling for Raydafon’s SWC-BF Standard Flex Flange Type Universal Coupling, and the difference was obvious right away. This universal coupling moves power smoothly and efficiently, even when we’re running it in high-stress conditions—it never lets up. The flexibility paired with its tough design keeps our machinery running without a hitch. Plus, Raydafon got the delivery to us fast, and their customer service was top-notch—made the whole purchase experience that much better. Highly recommend this reliable flex flange universal coupling!

⭐⭐⭐⭐⭐ Matteo Rossi, Operations Manager, Milan Industrial Solutions, Italy

We were on the hunt for a universal coupling that could handle misalignments well, and that’s how we found Raydafon’s SWC-BF Standard Flex Flange Type Universal Coupling. We’ve been using it for a few weeks now, and I can say for sure it checks all our boxes. Installing it was easy, no extra hassle, and even when we put it through challenging conditions, it holds up. The quality is outstanding for the price—definitely a smart investment for our machinery. I’m really happy with both the product and the service Raydafon gave us.

Raydafon isn’t just a manufacturer—we’re a leading supplier of top-tier transmission components and industrial machinery solutions, and we’ve got deep expertise in products like the SWC cardan shaft universal joint coupling. We started with innovation and quality at our core, and over time, we’ve grown our lineup to include gearboxes, drive shafts, hydraulic cylinders, pulleys, and advanced machine tools—all built to meet the tough demands of agricultural and heavy-duty industries. Our high-torque universal joint coupling solutions are crafted with care, making sure torque transfers smoothly and misalignments are handled right—they’re absolute must-haves for clients who need reliable heavy-duty universal joint coupling for rolling mill operations.

Our production facilities are state-of-the-art: we’ve got CNC workshops, grinding and heat treatment gear, and 3D measurement systems. We stick to strict standards like ISO9001/TS16949, so every industrial universal joint coupling we make is precise and built to last. Take our durable SWC universal joint shaft coupling in lifting and material handling equipment, for example—it’s optimized for places that need serious load-bearing power. And our SWC heavy-duty universal joint coupling? It solves problems in heavy machinery universal joint coupling systems, where staying stable under extreme conditions is non-negotiable.

We’re big on global reach too—80% of our products get exported to markets like the US, Germany, Japan, Italy, Malaysia, Australia, and the Middle East. We’ve got a strong network across China, South Korea, the UK, Singapore, the US, and Spain, which lets us create custom efficient universal joint coupling for large power transmission options. These are tailored to specific needs, like our energy-saving universal joint coupling solutions that hit up to 98.6% transmission efficiency—cutting down energy use in high-power setups.

Sustainability and client-focused innovation matter to us. That’s why we offer low-noise universal joint coupling options that keep noise between 30-40 dB(A)—perfect for industrial spots where noise is a concern. And we back everything up with full after-sales support. Our commitment to doing things right makes Raydafon a reliable partner in the transmission industry, helping professionals get the best performance and reliability out of their equipment.

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Tel

+86-574-87168065

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Copyright © Raydafon Technology Group Co.,Limited All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |