QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Raydafon’s SWC-BH Standard Flex Welding Type Universal Coupling is engineered specifically for heavy-duty torque transfer in demanding heavy machinery scenarios—think rolling mills, cranes, and mining equipment that operate under constant high stress.

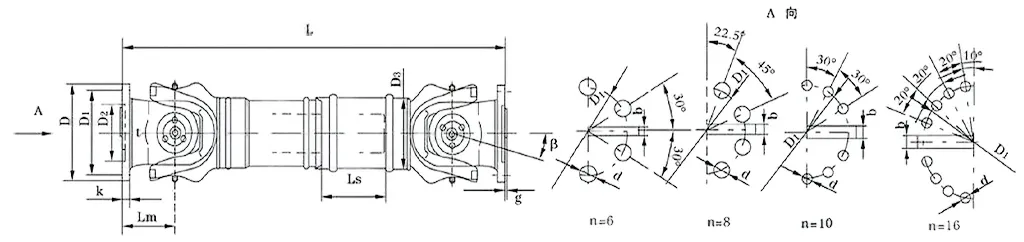

It comes with a welded yoke as a key design feature, and its gyration diameters span a practical range: from 180mm all the way up to 620mm. What sets it apart for tough jobs is its ability to handle angular misalignments of up to 15 degrees, plus it can take on torque loads as high as 1250 kN·m—both critical for keeping operations steady even in harsh working conditions.

Build quality is focused on durability: the coupling uses high-strength 35CrMo steel for long-lasting toughness, paired with precision needle bearings to ensure smooth, reliable performance over time. This makes it a go-to choice for two key needs: universal couplings tailored for heavy machinery, and welded universal couplings suited for industrial-grade applications.

Raydafon manufactures this coupling in China, and all production follows ISO 9001 standards to guarantee consistent quality. On top of that, it offers custom options to fit specific requirements—all at prices that stay competitive for businesses looking for both reliability and value.

| No. | Gyration diameter D mm | Nominal torque Tn KN·m | Axes fold angle β (°) | Weary torque Tf KN·m | Flex quantity Ls mm | Size (mm) | Rotating inertia kg.m2 | Weight (kg) | |||||||||||

| Lmin | D1 (js11) | D2 (H7) | D3 | Lm | n-d | k | t | b (h9) | g | Lmin | Increase 100mm | Lmin | Increase 100mm | ||||||

| SWC58BH | 58 | 0.15 | 0.075 | ≤22 | 35 | 325 | 47 | 30 | 38 | 35 | 4-5 | 3.5 | 1.5 | - | - | - | - | 2.2 | - |

| SWC65BH | 65 | 0.25 | 0.125 | ≤22 | 40 | 360 | 52 | 35 | 42 | 46 | 4-6 | 4.5 | 1.7 | - | - | - | - | 3 | - |

| SWC75BH | 75 | 0.5 | 0.25 | ≤22 | 40 | 395 | 62 | 42 | 50 | 58 | 6-6 | 5.5 | 2 | - | - | - | - | 5 | - |

| SWC90BH | 90 | 1 | 0.5 | ≤22 | 45 | 435 | 74.5 | 47 | 54 | 58 | 4-8 | 6 | 2.5 | - | - | - | - | 6.6 | - |

| SWC100BH | 100 | 1.5 | 0.75 | ≤25 | 55 | 390 | 84 | 57 | 60 | 58 | 6-9 | 7 | 2.5 | - | - | 0.0044 | 0.00019 | 6.1 | 0.35 |

| SWC120BH | 120 | 2.5 | 1.25 | ≤25 | 80 | 485 | 102 | 75 | 70 | 68 | 8-11 | 8 | 2.5 | - | - | 0.0109 | 0.00044 | 10.8 | 0.55 |

| SWC150BH | 150 | 5 | 2.5 | ≤25 | 80 | 590 | 13 | 90 | 89 | 80 | 8-13 | 10 | 3 | - | - | 0.0423 | 0.00157 | 24.5 | 0.85 |

| SWC160BH | 160 | 10 | 5 | ≤25 | 80 | 660 | 137 | 100 | 95 | 110 | 8-17 | 15 | 3 | 20 | 12 | 0.145 | 0.006 | 68 | 1.72 |

| SWC180BH | 180 | 20 | 10 | ≤25 | 100 | 810 | 155 | 105 | 114 | 130 | 8-17 | 17 | 5 | 24 | 14 | 0.175 | 0.007 | 70 | 2.8 |

| SWC200BH | 200 | 32 | 16 | ≤15 | 110 | 860 | 170 | 120 | 127 | 135 | 8-17 | 19 | 5 | 28 | 16 | 0.31 | 0.013 | 86 | 3.6 |

| SWC225BH | 225 | 40 | 20 | ≤15 | 140 | 920 | 196 | 135 | 152 | 120 | 8-17 | 20 | 5 | 32 | 9 | 0.538 | 0.0234 | 122 | 4.9 |

| SWC250BH | 250 | 63 | 31.5 | ≤15 | 140 | 1035 | 218 | 150 | 168 | 140 | 8-19 | 25 | 6 | 40 | 12.5 | 0.966 | 0.0277 | 172 | 5.3 |

| SWC285BH | 285 | 90 | 45 | ≤15 | 140 | 1190 | 245 | 170 | 194 | 160 | 8-21 | 27 | 7 | 40 | 15 | 2.011 | 0.051 | 263 | 6.3 |

| SWC315BH | 315 | 125 | 63 | ≤15 | 140 | 1315 | 280 | 185 | 219 | 180 | 10-23 | 32 | 8 | 40 | 15 | 3.605 | 0.0795 | 382 | 8 |

| SWC350BH | 350 | 180 | 90 | ≤15 | 150 | 1410 | 310 | 210 | 267 | 194 | 10-23 | 35 | 8 | 50 | 16 | 7.053 | 0.2219 | 582 | 15 |

| SWC390BH | 390 | 250 | 125 | ≤15 | 170 | 1590 | 345 | 235 | 267 | 215 | 10-25 | 40 | 8 | 70 | 18 | 12.164 | 0.2219 | 738 | 15 |

| SWC440BH | 440 | 355 | 180 | ≤15 | 190 | 1875 | 390 | 255 | 325 | 260 | 16-28 | 42 | 10 | 80 | 20 | 21.42 | 0.4744 | 1190 | 21.7 |

| SWC490BH | 490 | 500 | 250 | ≤15 | 190 | 1985 | 435 | 275 | 325 | 270 | 16-31 | 47 | 12 | 90 | 22.5 | 32.86 | 0.4744 | 1452 | 21.7 |

| SWC550BH | 550 | 710 | 355 | ≤15 | 240 | 2300 | 492 | 320 | 426 | 305 | 16-31 | 50 | 12 | 100 | 22.5 | 68.92 | 1.357 | 2380 | 34 |

When we talk about heavy-duty industrial gear that keeps power flowing reliably, the SWC universal joint coupling (often called the SWC cardan shaft universal joint coupling) is a non-negotiable part. You’ll find it hard at work in setups like rolling mills, hoisting machinery, and all kinds of tough heavy machinery systems—places where cutting corners on power transmission just isn’t an option.

Its main job? Connect two transmission shafts that don’t line up perfectly (non-coincident axes) and make sure power keeps moving without a hitch, even when the operating conditions get rough. No stutters, no breaks—just steady transfer when it matters most.

Let’s break down its key specs that make this performance possible:

Gyration diameter: Ranges from φ58 to φ620, covering a wide span of industrial needs.Nominal torque: Handles anywhere from 0.15 kN·m up to 1000 kN·m—enough muscle for even high-torque demands.Axis fold angle: Can take angles up to 25° without compromising function, perfect for shafts that can’t stay perfectly aligned.

Where does it stand out the most? Think rolling mill operations—where it acts as a reliable heavy-duty universal joint coupling that holds up under the mill’s intense pressure. Or in lifting and material handling equipment, where as a durable SWC universal joint shaft coupling, it keeps things stable even when loads get severe. It doesn’t just work—it keeps operations steady when the going gets tough.

The SWC universal joint coupling isn’t just thrown together—it’s engineered from the ground up to stand tough in industrial settings, with features that boost both performance and longevity. Let’s take a close look at what makes its structure work so well.

Smart, Secure Design

At its core is an integrated fork head design—no separate pieces held together by bolts here. This matters because it cuts down on the risk of bolts coming loose or snapping, a common headache with other setups. In fact, this design ups the structural strength by 30% to 50% compared to older styles. For anyone relying on a heavy machinery universal joint coupling, that means fewer breakdowns when things get intense. It’s the kind of robust universal joint coupling that keeps running smoothly, even in high-stress environments where other parts might fail.

Built to Carry the Load

This isn’t your average connector. The SWC heavy-duty universal joint coupling is made to handle serious weight—think mining gear, construction machinery, and other heavy hitters. When you need a rugged universal joint coupling that won’t back down under pressure, this is the one that delivers. It’s not just about size; it’s about materials and engineering working together to take on the heft without wearing out fast.

Moves Power Efficiently

Ever wonder where all the energy goes in big industrial setups? Not much gets wasted here. This high-torque universal joint coupling hits efficiency levels up to 98.6%, which means less energy lost as heat or friction. For operations looking to cut costs, that’s a big win. It’s the kind of efficient universal joint coupling that makes a difference in large power transmission systems, acting as a reliable universal joint coupling that keeps energy bills in check.

Quiet and Steady

Loud machinery can be a real problem, especially in spaces where noise matters. The SWC universal joint coupling keeps things calm, with noise levels usually between 30-40 dB(A)—quieter than a normal conversation. That makes it a great low-noise universal joint coupling for environments where keeping sound down is key, without sacrificing the reliability you need. Whether it’s in a factory floor or a precision workshop, this smooth-running universal joint coupling gets the job done without the racket.

The SWC-BH Standard Flex Welding Type Universal Coupling isn’t just another part—it’s a workhorse built to move power efficiently, even when machines are under heavy stress. Let’s break down where it really shines.

Take heavy machinery and construction gear, for example. When you’re dealing with extreme loads and constant vibrations—think excavators or bulldozers—this coupling doesn’t back down. Its welded design adds extra toughness, so it outlasts flimsier options that might crack or wear out from all that movement. It’s the kind of high-torque universal coupling that keeps the power flowing, no matter how rough the job gets.

In factories, especially on conveyor lines and assembly systems, precision matters. This industrial-grade universal coupling handles angles and shifts in alignment without skipping a beat, keeping speeds steady. That means less time fixing breakdowns and more time keeping production on track. Engineers like it because it adapts to axial, radial, and angular misalignments—little shifts that can throw other parts off.

Over in automotive and transportation, drive shafts need something reliable to pass power smoothly. The SWC-BH fits right in, whether it’s in trucks, trains, or other vehicles. Its flex welding design makes it easy to slot into existing setups, handling high speeds without cutting corners on safety. It’s the go-to drive shaft universal coupling for keeping things moving.

Marine and offshore work is tough on equipment—saltwater, harsh weather, unpredictable loads. This coupling holds its own here, too. As a corrosion-resistant marine universal coupling, it stands up to salt spray and rough seas, keeping ship engines and auxiliary machines running consistently. No rust-related failures, no unexpected shutdowns.

Renewable energy setups like wind turbines and solar trackers need parts that don’t waste energy. The SWC-BH steps up as a renewable energy universal coupling, transferring power with barely any backlash. It meets global quality standards, so whether it’s in a wind farm in Europe or a solar plant in Asia, it delivers.

At Raydafon, we don’t just sell these couplings—we tailor them. Need a specific size, material, or torque capacity? Our team tweaks the SWC-BH to fit your exact needs. Reach out, and we’ll help you get the most out of your system.

When you’re looking for someone to trust with mechanical components—especially things like the SWC-BH Standard Flex Welding Type Universal Coupling—Raydafon isn’t just another option. We’re a manufacturer that lives and breathes quality, and that shows in every part we make.

First off, quality isn’t an afterthought for us. We use top-tier engineering techniques and put every single universal joint coupling—whether it’s a high-torque one for heavy machinery or an industrial-grade model for factory setups—through strict checks. Every part meets ISO 9001 standards, and we test them hard: extreme loads, rough conditions, whatever your industry throws at it. The goal? No unexpected failures, less risk for your operations, and a coupling that keeps your systems running smoothly.

Then there’s the customization. Let’s be real—no two jobs are the same. Maybe you need a drive shaft universal coupling with specific dimensions, or a marine propulsion universal coupling made from corrosion-resistant material, or even a renewable energy universal coupling tuned for just the right torque. We don’t make you fit a “one-size-fits-all” part. Tell us what you need, and we’ll tailor it to slot right into your existing setup—whether that’s in automotive, marine, or solar/wind systems.

And we get that cost matters, too. You shouldn’t have to choose between a good coupling and a fair price. We’ve optimized our supply chain and scaled our production so we can offer competitive rates on even specialized parts—like that marine propulsion universal coupling or high-torque industrial model—without cutting corners on quality. It’s about giving you value that lasts, not just a cheap part that fails fast.

Our team doesn’t disappear once you hit “order,” either. From the first call—when you’re trying to figure out which universal joint coupling works best for your renewable energy gear or factory line—to after-sales support if you have questions, we’re here. We’ve got years of industry know-how, so we can guide you to the right choice, help you avoid downtime, and make sure your coupling does exactly what you need it to.

At Raydafon, we’re not just selling parts—we’re building partnerships. We want to be the team you trust to keep your operations moving forward, with universal joint solutions that work as hard as you do. If you’ve got specific needs, reach out to our specialists today—let’s talk about how we can help.

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Tel

+86-574-87168065

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Copyright © Raydafon Technology Group Co.,Limited All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |