QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

| Parameter | Specification |

| Model Number | EP-TF1304.55.012 |

| Bore Diameter | 100 mm |

| Rod Diameter | 40 mm |

| Stroke Length | 200 mm |

| Installation Distance | 535 mm (Retracted, center-to-center) |

| Construction Type | Heavy-Duty Welded Body |

| Rated Working Pressure | 250 Bar (3625 PSI) |

| Proof Pressure | 375 Bar (5437 PSI) (Tested at 1.5x Rated Pressure) |

| Calculated Push Force | Approx. 20,800 lbf (92.5 kN) @ 250 Bar |

| Calculated Pull Force | Approx. 17,670 lbf (78.6 kN) @ 250 Bar |

| Standard Port Type | (Specify, e.g., #8 SAE O-Ring Boss / G1/2") |

| Operating Temperature | -25°C to +100°C (with standard seals) |

Swapping out your old cylinder for the EP-TF1304.55.012 Hydraulic Lift Cylinder is a smart move, but to get the most out of this rugged hydraulic lift cylinder, you’ll want to pair it with the right parts. Let’s talk about what works best.

Start with hydraulic control valves—these little workhorses need to keep up with the cylinder’s flow demands. If your valve’s GPM/LPM rating is too low, it’ll clog up the system, slowing down the industrial hydraulic lift cylinder’s movement. No one wants a laggy setup, so matching the valve to the cylinder’s needs is non-negotiable.

Then there’s the hydraulic pump. If you’re upgrading to a beefier hydraulic lift cylinder like this one, your current pump might not cut it. You’ve got to check if it can push enough fluid to keep the cylinder moving at the speed you need. An undersized pump will hold back even the toughest heavy-duty hydraulic lift cylinder, so don’t skip this check.

And let’s not overlook the basics: top-shelf hydraulic fluid and filters. Think of them as the lifeblood of your hydraulic lift cylinder. Clean fluid keeps the seals in shape, stopping leaks and wear that can tank performance. Skimping on cheap fluid or old filters is a fast way to shorten the life of this reliable hydraulic lift cylinder—so splurge a little here, it’s worth it.

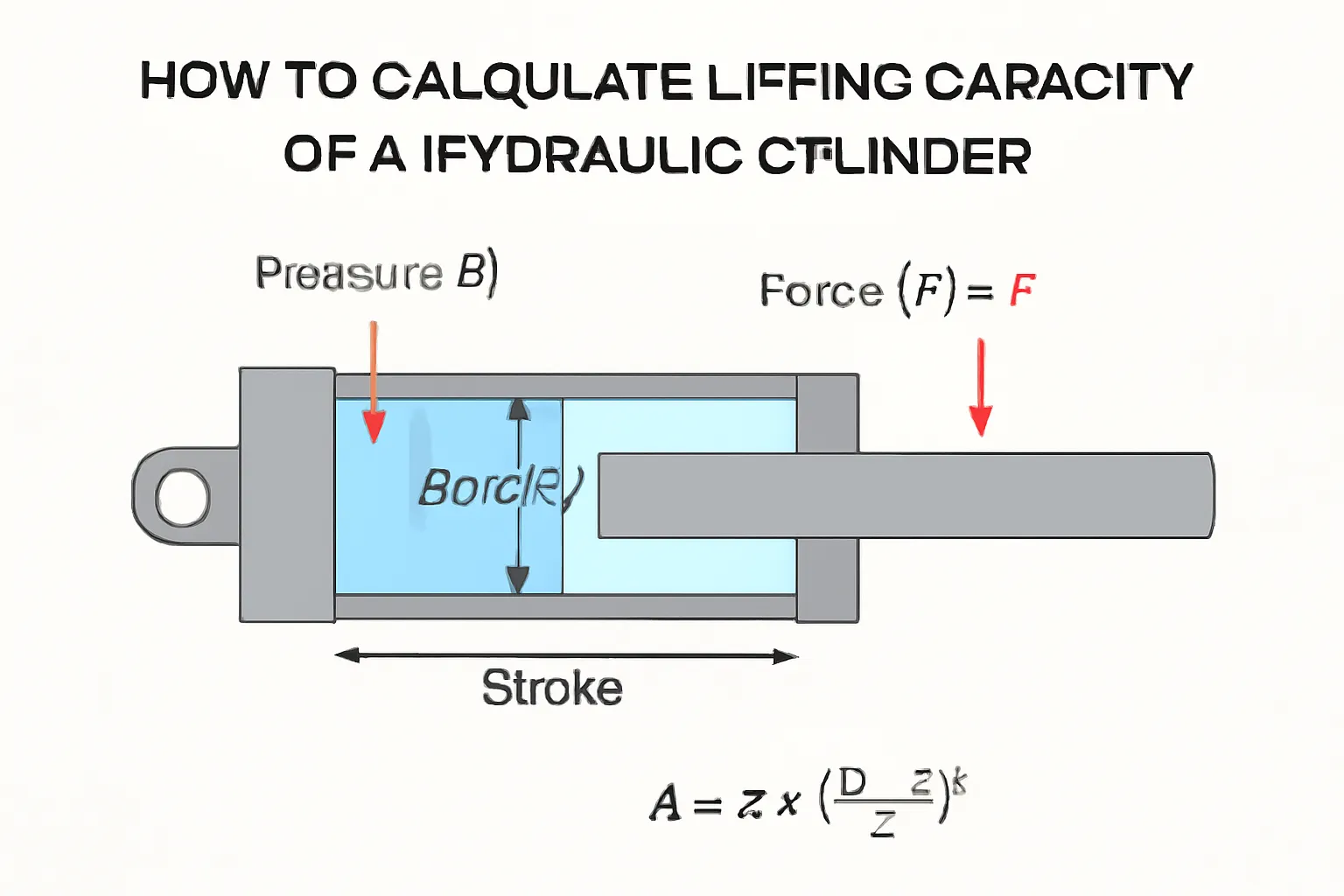

Figuring out how much a hydraulic cylinder can lift isn’t just some math exercise—it’s key to picking the right one for your gear. Whether you’re using a hydraulic lift cylinder for scissor lifts, moving materials straight up, or hoisting cars, getting the size right keeps things safe, working well, and from costing more than needed.

Start with the basic formula—no need to overcomplicate it. The lifting force comes down to pressure times the cylinder’s effective area. In metric, that’s Force (in Newtons) = Pressure (Pascals) × Area (square meters). For imperial, it’s Force (pounds) = Pressure (PSI) × Area (square inches). To get the area, just use π times (half the bore diameter) squared. Let’s say you’ve got a heavy-duty hydraulic lift cylinder with a 100mm bore (that’s about 3.94 inches) running at 200 bar (roughly 2,900 PSI). The area would be 3.14 times (0.05 meters squared), which is 0.00785 square meters. Multiply that by 200×10⁵ Pascals, and you’re looking at around 15,700 Newtons of force—plenty to handle tough loads.

Next, don’t forget the stroke length. How high you need to lift depends on that. Whether it’s a compact hydraulic lift cylinder for dock levelers or a long-stroke one for telescopic lifts, make sure the stroke matches the vertical movement you need. Too short, and you can’t reach; too long, and you’re wasting space.

Then there’s real-world stuff that cuts into that theoretical force—friction, the angle the cylinder’s mounted at, how fast it’s moving. That’s why you add a safety factor, usually 1.2 to 1.5. For vertical hydraulic lifting cylinders in critical spots like elevators or aerial platforms, that extra margin isn’t optional—it’s a must to keep things safe.

Finally, check how the cylinder’s mounted. The way it’s attached affects how well it transfers force. If you’re using an OEM hydraulic lift cylinder in a custom setup, make sure the mounting points can handle the full load without bending or wearing out. Whether you need a single-acting hydraulic lift cylinder for lifting tables or a double-acting one for vertical jobs, our team at Raydafon can help nail the right size and setup. Just tell us the load, stroke, and pressure, and we’ll guide you to the right hydraulic lift cylinder for the job.

Q1: How do I know if my current cylinder is undersized for the job?

A: Common signs include an inability to lift the machine's rated load, very slow operation even when the engine is at high RPM, or your system's pressure relief valve activating frequently during normal use.

Q2: What are the signs of an internal piston seal leak?

A: The most obvious sign is "cylinder drift," where a raised load slowly lowers itself without any control input. You may also notice a loss of power and slower-than-normal cycle times.

Q3: Can I simply replace my cylinder with a larger one to get more power?

A: While a larger bore cylinder provides more force, you must ensure the rest of your system (pump, valves, hoses) can provide adequate flow. You must also verify that the new cylinder's physical dimensions and mounting points will fit your machine. Consult a specialist if you are unsure.

Q4: My hydraulic cylinder is leaking from the end where the rod comes out. What does this mean?

A: This indicates a failure of the rod seal, likely caused by a scored or damaged rod, contamination, or simple wear and tear. The EP-TF1304.55.012's heavy-duty wiper and hard chrome rod are designed to minimize this common problem.

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Tel

+86-574-87168065

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Copyright © Raydafon Technology Group Co.,Limited All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |