QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

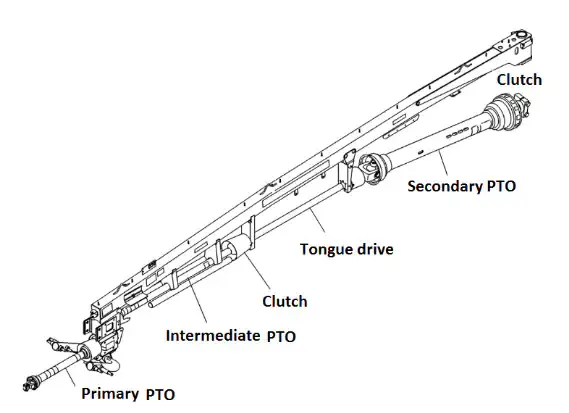

All disciplines use multiple PTO shafts and a combination clutch.

The types of PTO shafts and clutch locations vary from model to model.

Models below were initially equipped with Replacement of Weasler and Replacement of Bondioli & Pavesi PTO shafts.

| Part Number | Tractor | Implement | Description |

| New Holland Discbines 1431, 1432 | |||

| 14656853 | 1.375-21 | 1.5" x 23 spline | 55N 80x50 Double CV |

| 82-14656853 | none | 1.5" x 23 spline | 55N 50 degrees CV half(implement) |

| 83-14656853 | 1.375-21 | none | 55N 80 degrees CV half(tractor) |

| 83-14756853 | 1.750-20 | none | 55N 80 degrees CV half(tractor) |

| New Holland Discbines Model 411 | |||

| 14656853 | 1.375-21 | 1.5" x 23 spline | 55N 80x50 Double CV |

| 82-14656853 | none | 1.5" x 23 spline | 55N 50 degrees CV half(implement) |

| 83-14656853 | 1.375-21 | none | 55N 80 degrees CV half(tractor) |

| 83-14756853 | 1.750-20 | none | 55N 80 degrees CV half(tractor) |

| 857-5521 | none | 1.375-21 | 55N 50 degrees CV clamp yoke only |

| New Holland Discbines 1409, 1410, 1411, 1412, 1441, 1442 | |||

| 55N-NH14XX-DISCBINE | 1.375-6 | none | CAT6 CV with 1.375-21 yoke |

| 14656848 | 1.375-21 | none | 55N CV without implementing yoke |

| 14756848 | 1.750-20 | none | 55N CV without implementing yoke |

| New Holland Discbines H7220, H7230, H7320, H7330, H7450, H7460, H7550, H7560 | |||

| 14605548 | 1.375-21 | none | 55N CV without implementing yoke |

| 14705548 | 1.375-21 | none | 55N CV without implementing yoke |

| Model: | Primary | Intermediate | Secondary | HP | RPM |

| H7220 | 35N CV |

|

35N Square | 65 | 540 |

| H7230 | 55N CV or standard | Jack style 1.375-21 | H8 double CV | 80 | 540/1000 |

| H7320 | 35N CV |

|

35N Square | 65 | 540 |

| H7330 | 55N CV or standard | Jack Style 1.375-21 | H8 double CV | 80 | 540/1000 |

| H7450 | 55N Double 80/50 CV or 55N standard (for swivel) |

|

55N standard | 90 | 1000 |

| H7460 | 55N Standard | 55N Square w/clutch | 55N Standard | 100 | 1000 |

| H7550 | 55N Double 80/50 CV or 55N standard (for swivel) | 55N standard | 55N standard | 90 | 1000 |

| H7560 | 55N Standard | 55N Square w/clutch | 55N standard | 100 | 1000 |

The multi-speed requirements of 540/750/1000rpm are suitable for the power interfaces of all agricultural machinery from tractors to combine harvesters. Its high-strength alloy steel shaft and self-lubricating bearing sleeve combination can continuously operate for 12 hours without jamming in the corn stalk harvesting in the black soil of Northeast China, and the torque attenuation rate is reduced by 40% compared with the traditional shaft, making it an "all-weather partner" for cross-regional operators.

For non-standard working conditions such as hills and wetlands, the product is equipped with ±30° universal adjustment + hydraulic damping shock absorption system, which successfully resolves the impact load caused by the height difference between the tractor and the baler in the potato harvesting scene of the Yunnan terraces. Its seals are made of hydrogenated nitrile rubber, which still maintains the IP67 protection level in the muddy environment of the Jiangnan plum rain season, avoiding repeated tillage losses caused by power transmission interruption.

The reinforced PTO Shaft designed for cotton harvesting in Xinjiang can carry a peak torque of 3,500Nm through a four-spherical roller bearing + quenched shaft tube structure, which perfectly matches the high load requirements of the John Deere CP690 cotton picker. Its torsional stiffness is 25% higher than the industry standard. After continuously picking 200 acres of cotton fields, the swing of the drive shaft is still controlled within 0.5°, significantly reducing the risk of gearbox overload.

In addition to agricultural scenarios, the PTO Shaft has successfully entered the field of engineering machinery with its adjustable speed clutch + emergency slip mechanism. In the stone crushing and screening operation of the Inner Mongolia mine, as a power connector to drive the vibrating screen, its intelligent overload protection function avoids equipment damage caused by stone jamming, and its efficiency is 18% higher than the belt drive solution, becoming an economical solution for light engineering machinery power upgrade.

Raydafon's PTO Shaft adopts a φ65mm hardened alloy steel shaft tube and a four-row tapered roller bearing design. The peak torque load reaches 4,500Nm, which can stably drive heavy-duty agricultural machinery such as deep tillers and combined tillers equipped with tractors with more than 300 horsepower. Its shaft body has been tempered and its surface hardness reaches HRC58-62. After 200 hours of continuous cultivation on the black soil in Northeast China, the swing of the drive shaft is still controlled within 0.3°, which is 60% more wear-resistant than similar products.

The integrated double-plate friction clutch + hydraulic damper can automatically slip and cut off the power within 0.2 seconds when encountering sudden resistance such as stones and tree roots, avoiding gearbox cracking or drive shaft distortion. Actual measurements at a farm in Xinjiang Corps show that after using this output shaft, the maintenance frequency of the tractor rear axle is reduced by 80%, and the service life of the supporting agricultural machinery is extended by 3-5 years, becoming a "safety valve" for high-risk operation scenarios.

For dusty/humid environments such as pastures and mines, the product uses a combination of three-lip skeleton oil seals + magnetic chip removal rings. After working continuously for 72 hours in the sandstorm weather on the Inner Mongolia grassland, the internal cleanliness of the universal joint still reaches the NAS level 6 standard. Its seals are made of fluororubber, with a temperature range of -50℃ to 150℃, successfully resisting the acid corrosion caused by silage fermentation, and becoming the "protective armor" of multinational pasture equipment.

The innovative use of non-welded shaft tube + spring connection structure does not require disassembly of the entire machine for maintenance, and the maintenance time of a single drive shaft is shortened to 15 minutes. Data from a European agricultural machinery cooperative shows that after using this design, the annual maintenance hours are reduced by 65% and the spare parts inventory cost is reduced by 40%. As a manufacturer directly supplied by Chinese factories, Raydafon provides non-standard customization services at a price 30% lower than that of European and American brands, becoming the first choice for cost-effective global agricultural machinery upgrades.

I am David Johnson. Our ranch has been using Raydafon's PTO Shaft for a long time. The fatigue resistance of this product is far beyond expectations. After driving the forage harvester for 12 hours, the temperature of the drive shaft is still 15℃ lower than similar products. What I appreciate even more is that when we encountered an extreme cold wave last year, the shaft did not break at -30℃. This stability keeps the attendance rate of ranch equipment above 98%. As a purchaser directly connected to Chinese factories, Raydafon not only provides very competitive prices, but also customizes the length of the drive shaft according to the size of our ranch. This flexible service is extremely rare among European and American brands.

I am James Wilson, a rancher from Queensland, Australia. Our ranch has been using Raydafon's PTO Shaft-driven disc mowers for a long time. This product has completely changed our perception of Chinese manufacturing - after continuously harvesting 2,000 acres of sugarcane fields, the wear-resistant coating of the drive shaft has almost no wear, and its torsion resistance even exceeds that of a well-known European brand. I look forward to our subsequent cooperation.

I am Giovanni Rossi from Italy. After changing to your product, even when I was dragging a fully loaded seed drill on uneven fields, the shaft body did not show any deformation, the universal joint rotated very flexibly, and even the metal friction sound was much smaller than before. I remember that when I received the goods, the package also came with a maintenance manual and spare sealing rings. This kind of service that pays attention to details makes me feel reliable from the bottom of my heart! Now this shaft has been used for eight months, and it is still as good as new!

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Tel

+86-574-87168065

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Copyright © Raydafon Technology Group Co.,Limited All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |