QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

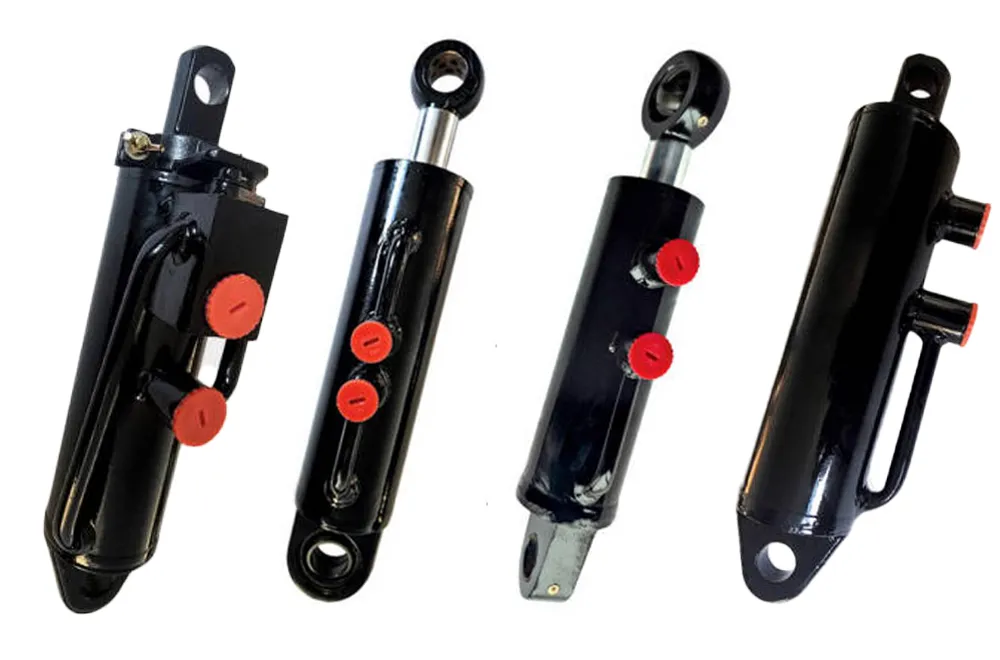

The Raydafon EP-TB600.55B.2 is one tough piece of machinery—this hydraulic lift cylinder doesn’t just get the job done, it keeps at it, no matter how rough things get. We built it with care, using high-strength materials that can take a beating, and every part’s been tuned to work in sync. Whether you’re out in the fields with agricultural gear, running industrial machinery, or keeping mobile equipment moving, this heavy-duty hydraulic lift cylinder brings the power and sturdiness you need.

What really sets it apart is how well it balances strength and smoothness. It lifts with steady force, no jerking or lag, which makes it a standout for new systems that need reliable performance right from the start. But it’s just as handy as a replacement hydraulic lift cylinder—slip it in where an old one wore out, and it’ll fit right in, working like it’s been there all along. For anyone needing an industrial hydraulic lift cylinder that doesn’t cut corners on durability or efficiency, this one’s a solid pick.

| Specification | Value |

| Model Number | EP-TB600.55B.2 |

| Bore Diameter | 75 mm |

| Rod Diameter | 32 mm |

| Stroke Length | 110 mm |

| Installation Distance | 425 mm (Retracted, center-to-center) |

| Working Pressure (Rated) | 210 Bar (3045 PSI) |

| Max Pressure (Peak) | 250 Bar (3625 PSI) |

| Cylinder Type | Typically Double-Acting (Contact for Single-Acting) |

| Port Type | (Specify common port, e.g., G3/8" or #8 SAE ORB) |

| Mounting Style | (Specify common mounting, e.g., Clevis End) |

| Operating Temperature | -20°C to +90°C |

Let’s dig into what makes up the EP-TB600.55B.2 hydraulic lift cylinder – every part’s picked with a purpose, so this heavy-duty hydraulic lift cylinder can handle the rough stuff day in, day out. Start with the cylinder barrel: it’s made from cold-drawn, high-tensile steel. The inside gets a super smooth honing, down to a micro-finish of Ra < 0.4μm. This isn’t just for looks – it lets the seals do their job right, cuts down on friction inside, and that’s what keeps a reliable hydraulic lift cylinder working hard in busy setups.

Then there’s the piston rod. We start with high-strength steel, machine it to exact specs, and give it an induction hardening treatment. After that, it’s polished to a shine and coated with a thick layer of hard chrome. The payoff? A surface tough enough to resist scratches, stand up to rust, and take a beating without wearing out. That’s why this industrial hydraulic lift cylinder lasts longer, even when used in rough conditions.

The piston’s made from ductile iron – strong, and it doesn’t wear down easy. To keep things running smooth, we fit it with a top-notch wear band. It’s a small part, but it stops metal from rubbing directly on the cylinder barrel, and that little detail goes a long way in protecting the hydraulic lift cylinder.

Finally, the gland and seals. The rod gland holds a whole set of sealing parts: a polyurethane U-cup rod seal to keep fluid from leaking out, a wiper seal to keep dirt and grime from getting in, and wear bands to keep everything lined up right. All these pieces work together to make sure this engineering hydraulic lift cylinder stays leak-free and clean, even when it’s being pushed hard.

The EP-TB600.55B.2 hydraulic lift cylinder is built so every part pulls its weight—let’s break down how these features make a real difference for your work.

First off, the build is tough as nails, and that’s no accident. The barrel and rod are forged from high-tensile steel, way beyond basic standards. This isn’t just any heavy-duty hydraulic lift cylinder; it’s made to take the hits—shock loads, endless cycles, the kind of abuse common in farms and construction sites. Less breakdowns mean less time stuck waiting, and over time, that adds up to lower costs all around.

Leaks? They’re the bane of hydraulic systems, but this industrial hydraulic lift cylinder fights back with a sealing setup that’s got layers. We’re talking a primary rod seal to lock in fluid, a buffer seal to soak up pressure spikes, and an outer wiper to brush off dirt. Together, they stop leaks cold—no fluid loss, no pressure drops, and nothing seeping out to mess with the environment. That’s the kind of reliability you need from a heavy-duty hydraulic lift cylinder.

Then there’s the cylinder barrel, honed to a shine you could almost check your reflection in. That ultra-smooth finish isn’t for looks. It cuts down on friction where the piston meets the barrel, so the seal lasts longer and the whole thing moves smoother. For a high-performance hydraulic lift cylinder, that means more efficient operation—less wasted energy, more consistent lifting power, and a longer life for the whole assembly.

The piston rod? It’s out in the open, taking the brunt of the elements, so we gave it a thick coat of hard chrome—20 to 30 microns thick. That creates a surface tough enough to shrug off dents, scratches, and even rust from rain or mud. Whether it’s caked in dirt on a farm or exposed to harsh weather on a job site, this rugged hydraulic lift cylinder keeps performing, no matter what gets thrown at it.

The EP-TB600.55B.2 is built to be a workhorse, with a design that fits right into all sorts of jobs across different fields—no wonder it’s such a go-to hydraulic lift cylinder for so many.

Take agriculture, for example. This 75mm bore hydraulic lift cylinder is practically made for farm work. Tractors rely on it to power the 3-point hitch, lifting heavy implements like plows and cultivators with ease. When it’s time to plant or till, it’s the one actuating seeders and harrows, keeping things moving smoothly. Even front-end loaders benefit—this agricultural hydraulic lift cylinder powers bale spears and grapples, making light work of hauling hay or moving debris. And for those big commercial mowers, it’s the muscle behind adjusting the mower deck height, ensuring a clean cut every time.

Over in construction and material handling, it’s just as handy. Skid steers depend on this heavy-duty hydraulic lift cylinder to run buckets, grapples, and augers—tough jobs that need consistent power. Small forklifts use it too, for lifting and tilting the mast, so pallets go exactly where they need to. Aerial work platforms? The scissor mechanisms in smaller lifts rely on its precision to raise and lower safely. Even conveyor belts stay tight and efficient, thanks to this hydraulic lift cylinder handling tensioning duties without a hitch.

Industrial automation is another area where it shines. Lifting tables in factories? This industrial hydraulic lift cylinder is the main force lifting workbenches and assembly platforms, steady as can be. When manufacturers need to clamp or press workpieces in jigs, it’s there to apply just the right pressure. And those heavy industrial gates and doors? They slide open and shut smoothly, all because this reliable hydraulic lift cylinder is behind the automation.

Specialized vehicles aren’t left out either. Smaller tow trucks use it to operate wheel lifts and booms, getting cars onto the flatbed without a fuss. Log splitters? This hydraulic lift cylinder is the ram that powers through tough wood, making firewood prep a breeze. Even small to medium dump trailers count on it—when it’s time to unload, this hardworking hydraulic lift cylinder lifts the bed steady and strong, getting the job done right.

At Raydafon, we know the parts we make are the backbone of your equipment’s performance—we’re not just selling you something, we’re in this with you, invested in making sure you succeed. That’s why every step of how we build things, and how we check their quality, is done with that focus in mind.

Take our manufacturing process: we don’t cut corners. From picking out the raw steel for a heavy-duty hydraulic lift cylinder to putting the final pieces together, every move is tracked and recorded. Our shops are kitted out with modern CNC machines, so each part comes out precise, no guesswork. And when we weld, we use automated systems that lay down strong, even welds—critical for something like a high-pressure hydraulic lift cylinder that’s going to take a lot of stress. We stick tight to ISO standards through it all, not because it’s a box to check, but because it’s how we make sure every industrial hydraulic lift cylinder is built right.

Then there’s the pressure testing—no exceptions. Every single EP-TB600.58.2 hydraulic lift cylinder gets put through its paces before it leaves our doors. We crank the pressure up to 1.5 times what it’s rated for, just to be sure. This isn’t about being tough for the sake of it; it’s to prove the seals hold, the welds don’t budge, and that when you bolt this hydraulic lift cylinder into your machine, it’s ready to go—no leaks, no surprises, just reliable work.

What makes partnering with Raydafon worth it? For starters, our engineers aren’t just desk-bound—they know hydraulic lift cylinders inside out. Whether you need help picking the right standard model or want a custom hydraulic lift cylinder tailored to your gear, they’ll hash out the details with you. And since we’re the ones making the cylinders, there’s no middleman marking things up—you get a quality hydraulic lift cylinder at a fair price.

Support? We’re on it. Whether you’ve got questions before you buy or need help after, our team doesn’t drag their feet. And we keep a solid stock of parts, so when you need a replacement hydraulic lift cylinder or a new one for a project, we can get it to you on time. It all comes down to this: we want you to trust that when you choose Raydafon, you’re getting a hydraulic lift cylinder that’s built to keep your equipment—and your business—running strong.

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Tel

+86-574-87168065

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Copyright © Raydafon Technology Group Co.,Limited All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |