QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Raydafon's EP-NF75B hydraulic lift cylinder is, to put it bluntly, designed for tough, heavy tasks. Its single-acting plunger design offers the advantage of a single-direction force, delivering exceptionally strong performance. It's particularly well-suited for heavy lifting and pushing tasks in tight spaces where work must be done quickly, minimizing space and delivering high efficiency.

This cylinder is truly exceptionally durable. The barrel is constructed of high-strength alloy steel with uniformly ground walls, and the plunger has been specially hardened with multiple layers of treatment, ensuring it withstands even the slightest bumps and dents. This isn't a sloppy process; the factory's CNC lathes are so precise that even a 0.01mm discrepancy in component dimensions is unacceptable. They also have a dedicated seal test bench where they pump high-pressure oil into the cylinder for an entire day; even the slightest leak constitutes a failure. Thanks to these advanced equipment and meticulous inspections, this hydraulic cylinder is reliable and will last for seven or eight years, even under intense daily use.

The benefits are clear to customers. Dusty workshop with fluctuating temperatures? It keeps running smoothly without breaking down. Rough, windy, and sun-baked conditions on the construction site? Its rust-resistant coating withstands the elements and resists deterioration. Even in humid environments like ports, the seals resist deterioration and leaks due to moisture.

The EP-NF75B is defined by its industrial-grade specifications, meticulously balanced for optimal performance.

| Parameter | Specification | Engineering Details |

| Model Number | EP-NF75B |

Our specific identifier for this high-pressure hydraulic cylinder.

|

| Cylinder Type | Single-Acting, Ram Type |

Designed for push force in one direction; retraction by gravity or an external load.

|

| Cylinder Bore | 75 mm (2.95 in) |

The internal diameter of the cylinder, directly influencing the cylinder’s force output.

|

| Rod Diameter | 32 mm (1.26 in) |

The diameter of the piston rod, critical for stability and resistance to buckling under heavy loads.

|

| Stroke Length | 110 mm (4.33 in) |

The total travel distance of the piston rod, which determines the lifting range.

|

| Installation Distance | 350 mm (13.78 in) |

The center-to-center distance between mounting points when the cylinder is fully retracted.

|

| Max. Working Pressure | 250 bar (3625 PSI) |

The maximum operational pressure the cylinder is designed to withstand safely.

|

| Material | High-Strength Alloy Steel |

Sourced for superior toughness and resistance to impact and heavy loads.

|

| Seal Type | Advanced Polyurethane Seals |

Ensures a tight, leak-free seal and extends the service life.

|

| Mounting Style | Eyelet/Clevis with Pin | A versatile mounting style for easy integration into a wide range of machinery. |

The EP-NF75B hydraulic lift cylinder comes with a host of standout benefits that directly boost the performance, durability, and cost-effectiveness of our customers' equipment. Whether it’s heavy industrial work or precise agricultural tasks, this model stands out as a reliable solution, ready to meet all kinds of operational needs.

Durability and reliability are at the heart of what makes this cylinder shine. As a heavy-duty hydraulic lift cylinder, it’s built to last, even in tough environments. The cylinder barrel and piston rod are made from high-strength alloy steel, so they hold up against bending, rust, and wear—no matter if they’re exposed to dust, moisture, or extreme temperatures like those on construction sites or farm fields. To top it off, there’s advanced sealing tech: high-quality nitrile rubber seals with reinforced backup rings keep fluid from leaking and dirt from getting in, making sure it runs smoothly even after thousands of uses. We’re strict with quality checks, too. Every EP-NF75B hydraulic lift cylinder goes through tough tests, like pressure cycling and load endurance checks, to prove it can handle harsh conditions. For customers, this means less downtime, fewer replacements, and the peace of mind that their equipment—whether it’s a lift table or a farm tool—can count on this cylinder to keep working without a hitch.

This cylinder is a single-acting, ram-type design, which makes it efficient in both structure and operation—truly a budget-friendly hydraulic lift cylinder that doesn’t skimp on quality. Its simpler build has fewer moving parts than double-acting models, which cuts down on manufacturing complexity and means less maintenance. That translates to fewer parts to check or replace, saving long-term upkeep costs for both OEM clients and those buying replacement parts. As a source factory, we handle production in-house, so we can optimize how we source materials and run our manufacturing processes. This lets us offer the EP-NF75B at a competitive price. For small to medium-sized businesses, this balance of quality and affordability is perfect: it delivers all the lifting power needed without the high cost of over-engineered alternatives, so every penny spent brings real value.

The EP-NF75B is tuned for precision, earning its spot as a high-precision hydraulic lift cylinder in its class. With a well-matched 75mm bore and 110mm stroke, it puts out a strong one-way force—up to 15,000 N—perfectly suited for controlled lifting jobs. Whether raising a lift table to an exact height or tilting a farm hopper, its smooth, steady movement lets operators get precise positioning, reducing mistakes and making work flow better. It’s also compact (just 120mm when retracted) and lightweight (2.8kg), which helps when space is tight. This small size with big power means it fits easily into mobile gear like utility vehicles or portable hoists, where weight and size affect how well you can move them. For customers, this means equipment that runs more efficiently, uses energy better, and puts less strain on other parts.

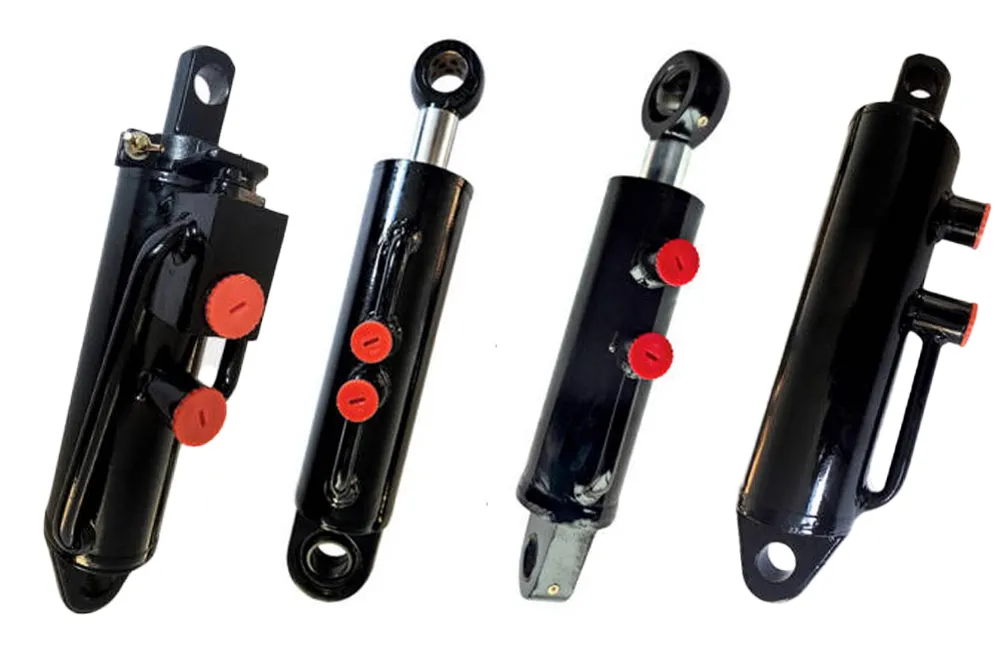

The EP-NF75B’s small but sturdy design makes it a versatile hydraulic lift cylinder across industries. In factories, it works great in lift tables, small hoists, and automated clamping systems—its precise stroke and force make moving materials easier. On farms, it powers lifting parts in small tractors, seeders, and feed mixers, handling everything from light loads to heavy tools with ease. To make it even more useful, we offer custom options, like adjustable stroke lengths and special mounting brackets, so it fits unique needs. Whether a customer needs a longer stroke for a custom lift or a rust-resistant coating for marine use, the EP-NF75B can be adjusted to fit over 30 different uses.

Beyond the cylinder itself, we’re committed to supporting our customers, and this customer-focused hydraulic lift cylinder support really shows with the EP-NF75B. Our technical team gives expert help during installation, making sure the cylinder fits into existing systems to work its best. If there’s a problem, we respond within 24 hours, giving step-by-step solutions to keep downtime short. We also provide detailed maintenance manuals and online resources to help customers take care of their cylinders—from tips on checking seals to when to change hydraulic fluid. For big orders, we offer on-site training so maintenance crews can keep the cylinders in top shape. This full support means a good experience from purchase to long-term use, making the EP-NF75B more than just a product—it’s a partner in our customers’ success.

The EP-NF75B hydraulic lift cylinder works on a simple idea that comes from the study of fluids. This is a very effective single-acting hydraulic lift cylinder that can turn hydraulic pressure into real linear thrust. This makes it useful for tasks that require constant pushing, lifting, or pressing of materials.

There is a piston and piston rod in the middle of this cylinder, which has been precisely machined. This means that it is a hydraulic lift cylinder of the ram type. The only way for pressurized hydraulic oil (usually a special kind) to get into the cylinder is through the inlet port. The oil fills the chamber and presses evenly on the surface of the piston. This pressure then turns into a strong straight force that pushes the piston rod outward to do things like lift heavy things, push mechanical parts, or compress materials. The force it makes depends a lot on the oil pressure and the size of the piston. It makes a lot of power for its size.

The EP-NF75B is a hydraulic lift cylinder that only works in one direction. It pushes out (the "working stroke") with the help of hydraulic oil and pulls back (the "return stroke") with the help of outside forces. High-pressure oil is pumped into the cylinder during extension. This pushes the piston rod out, which moves the load. Oil comes out of the inlet port when the rod pulls back. The rod can either pull back on its own weight (like when a lift table goes down) or be pulled back by extra devices like springs. This design gets rid of the need for complicated dual-port hydraulic systems, which makes maintenance easier and the EP-NF75B hydraulic lift cylinder stronger in tough conditions.

The EP-NF75B has a ram-type hydraulic lift cylinder, which means that the diameter of the piston rod is about the same as the diameter of the cylinder bore. This structure puts stability and strength first. The thick, strong rod won't bend even when it's carrying a lot of weight. This is important for heavy-duty jobs like lifting things in an industrial setting or running agricultural machinery. The ram-type design also keeps the cylinder small enough to fit in tight spaces while still being strong enough to lift, tilt, or press. It has the right amount of power and size to work with both moving and stationary machines.

Raydafon is a manufacturer of hydraulic cylinders and supporting steering components. Located in a major industrial city in Shandong, surrounded by veterans in the machinery manufacturing industry, our factory is incredibly familiar with the entire industry chain—from sourcing high-quality steel to precision machining, assembly, and testing, the entire process flows smoothly, enabling us to effectively control costs.

We primarily supply several major types of equipment: Agricultural vehicles rely on hydraulic cylinders for lifting plows and earth-moving shovels; excavators and loaders on construction sites rely on hydraulic cylinders for boom extension and extension; forklifts raising their forks and stackers lifting pallets in warehouses are also powered by our products; even the steering systems on ships and the winches on off-road vehicles can be found using our products.

In our workshops, stability and reliability are paramount. The production line is filled with CNC lathes and grinders, achieving precision down to a fraction of a hair's width. The inner wall of each cylinder must be polished to a smooth finish, and the piston rod must be evenly chrome-plated to prevent jamming and leaks. We're unwavering in our commitment to quality, adhering to ISO 9001 and ISO/TS 16949 standards, which are displayed on the wall and kept firmly in mind. Incoming raw materials must undergo ultrasonic testing, and finished products must withstand a test of 1.5 times the rated pressure. Even a single drop of oil leak constitutes a failure.

We're not afraid of special customer requests. For example, if a farmer complains about insufficient stroke on their tractor's cylinder, we can extend the piston rod. If a port customer is concerned about salt spray corrosion, we can double-chrome-plate and paint the cylinder. We even have customers who want to adjust the angle of the mounting trunnion, and our draftsmen can come up with a plan that same day. Whether it's original equipment for new machinery or replacing parts for older equipment, we can handle it—after all, a day a machine is down means a day's loss of revenue for our customers, and we want to ensure peace of mind.

Our products are now sold to over 30 countries. European and American customers appreciate our durability, while Southeast Asian clients appreciate our reasonable prices. A German customer once came for an inspection and spent an entire afternoon poring over our seal test bench. He gave it a thumbs-up, declaring it "more stringent than their local system." Ultimately, our goal is to ensure machines using perpetual motion cylinders experience fewer failures and more productive results—that's the real deal.

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Tel

+86-574-87168065

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Copyright © Raydafon Technology Group Co.,Limited All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |