QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

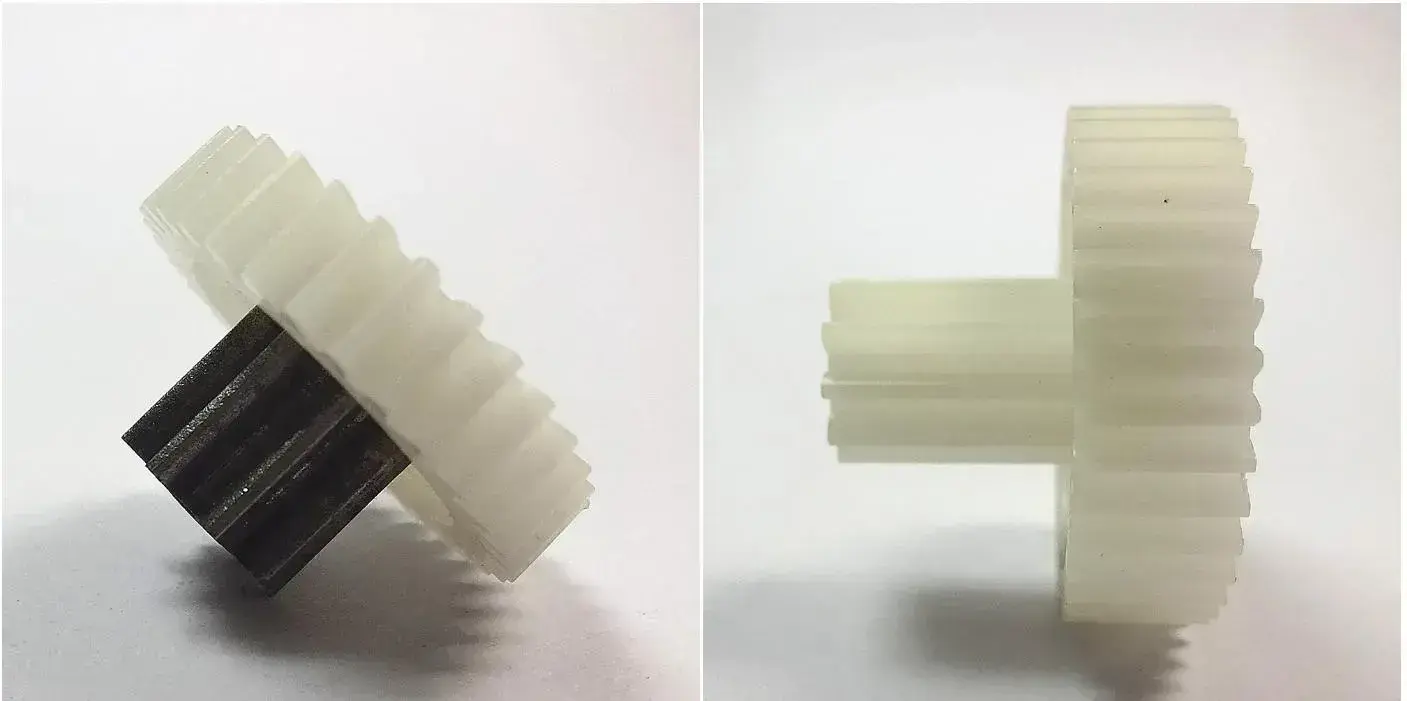

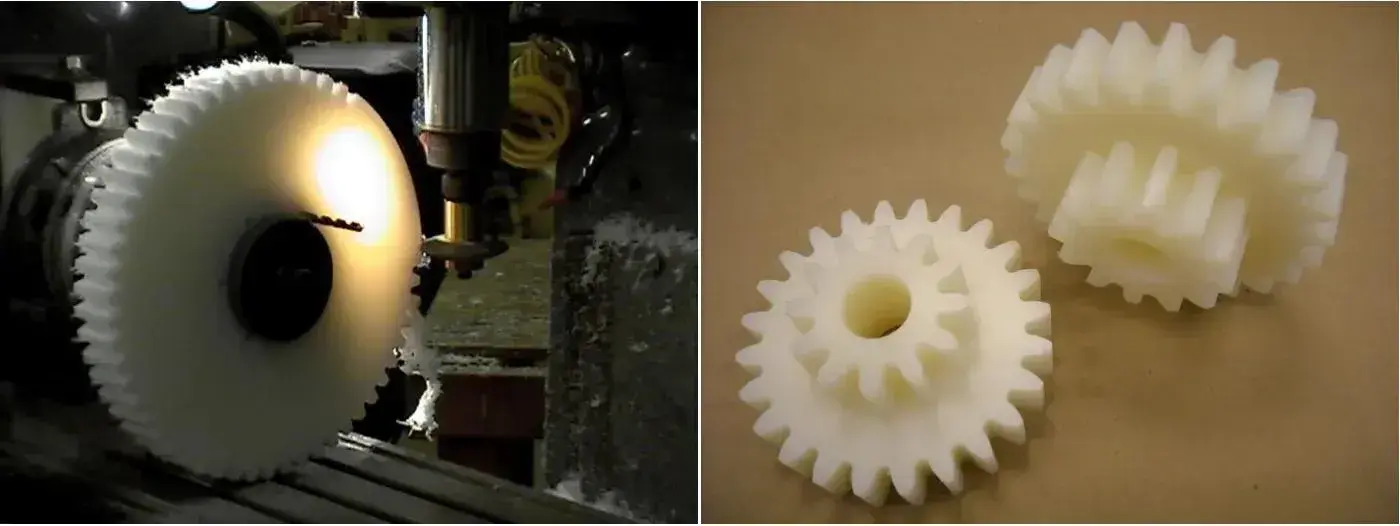

After years of hard work in the field of mechanical transmission, Raydafon, as a reliable manufacturer and supplier of plastic double spur gear in China, has fully utilized the advantages of its products with the solid technology of its own factory.

One of the killer features of plastic double spur gear is "easy to use"! Unlike metal gears that need to be oiled and maintained from time to time, the gears produced by Raydafon are made of engineering plastics with self-lubricating properties. After installation, they are like "perpetual motion machines", working silently without complaining about being tired, and the maintenance cost is directly reduced. The double-tooth design maximizes the transmission force. For gears of the same size, it can carry 30% more torque than single teeth. In high-intensity scenarios such as automated production lines, it can rotate continuously for thousands of hours without falling off.

In addition, this gear is so light that it can "float"! The weight is only one-third of that of metal gears. It is simply "the chosen one" when used in weight-sensitive equipment such as drones and medical devices. In addition, plastic is naturally corrosion-resistant. In a humid, acidic or alkaline environment, other gears may rust into "pockmarked faces", but this gear can remain smooth and new. Raydafon relies on large-scale production to keep costs to a minimum. The price it offers to customers is at the "King of Rolls" level in the market. You can use high-performance plastic double spur gear is for a small price, and the cost-effectiveness is directly maximized!

| Model Number | M1, M1.5, M2, M2.5, M3, M4, M5, M8, M12 and etc. |

| Material | PA, POM, UHMWPE, ABS, PTFE, PPS, Peek. |

| Standard | ISO, DIN, ANSI, JIS, BS, and Non-standard. |

| Precision | DIN6, DIN7, DIN8, DIN9. |

| Teeth treatment | Hardened, Milled, or Ground |

| Tolerance | 0.001mm-0.01mm-0.1mm |

| Finish | shot/sandblast, heat treatment, annealing, tempering, polishing, anodizing, zinc-plated |

| Items packing | Plastic bag+Cartons Or Wooden Packing |

| Payment terms | T/T, L/C |

| Production lead time | 20 business days for the sample, 25 days for the bulk |

| Samples | Sample price range from $2 to $100. sample express request paid by clients |

| Application |

1. Automatic controlling machine 2. Semiconductor industry 3. General industry machinery 4. Medical equipment 5. Solar energy equipment 6. Machine tool 7. Parking system 8. High-speed rail and aviation transportation equipment, etc. |

In the field of smart home, plastic double spur gear is the "hidden hero" of electric curtains and smart door locks. Electric curtains are frequently opened and closed every day, and metal gears are prone to noise. Raydafon's products, with its low noise characteristics, allows curtains to run silently; in smart door locks, it is light and wear-resistant, and can ensure long-term stable operation of the lock core even if the door is opened and closed dozens of times a day.

In terms of medical equipment, such as the lifting adjustment of dental chairs and the drug delivery device of infusion pumps, plastic double spur gear is indispensable. Its non-toxic and environmentally friendly plastic material meets medical standards and has extremely high precision. It can accurately control the operation of the equipment and ensure the safety of patients.

In 3C electronic devices, plastic double spur gear is also indispensable. The cooling fan adjustment structure of laptops and the paper transmission system of printers all use this gear. It is light in weight and will not increase the burden on the equipment. At the same time, it has excellent self-lubricating performance and can reduce the risk of damage to electronic components due to friction.

In the toy manufacturing industry, plastic double spur gear is hidden inside children's electric cars and remote-controlled robots. It is safe and durable, and is not easily damaged even if children play with it frequently. It is also affordable, helping toy manufacturers to improve product quality while controlling costs. As a supplier that ships directly from the factory, Raydafon uses its large-scale production advantages to provide customers in various industries with highly cost-effective product solutions.

I am Tom Brown from AutoMech Solutions in the United States. I ordered a batch of Plastic Double Spur Gear from Raydafon with a try-it-out mentality. I didn't expect that it would solve the big problem on our equipment! The gears we used before always made annoying clicking noises and often jammed. After replacing them with your products, the production line was as quiet as if the mute button was pressed, and the equipment operation became smooth and smooth. What's more surprising is that after almost half a year of high-intensity use, there are no obvious scratches on the surface of the gears. The wear resistance is really amazing!

Before placing the order, I sent more than a dozen emails to ask about the technical parameters. Your team replied in seconds every time and took the initiative to provide me with comparison suggestions for different models. The delivery speed was also amazingly fast. It took less than two weeks from ordering to receiving the goods, and our production progress was not delayed at all. I really think Raydafon is a conscientious company that understands both technology and service. I will look for you when purchasing gears in the future!

I am Marco Rossi from Meccanica Italia. I chose Raydafon products because of the wear resistance in the parameters. I didn't expect that the actual use was even more amazing than the data! After installing it on our food processing equipment, it has been running continuously for 8 hours without any slipping problems, and the noise is more than half less than the original metal gear.

What surprised me most was the after-sales response speed - last week I sent a message asking if the installation holes could be customized, and I received a detailed plan from the technical team on the same day, and the customized parts were sent to the factory a week later. This efficiency is really rare among European suppliers. The next batch of orders is already in process. I look forward to continued cooperation!

Hello Raydafon team! I am Lisa Morrison, an American customer. Last year, I used your Plastic Double Spur Gear in my factory in Florida. This product really solved our big problem. When we used metal gears before, they often rusted in the humid production environment, and they had to be frequently oiled and maintained. The noise was also very loud. After replacing it with your plastic double spur gear, there has been no problem for a whole year. Even in the workshop with corrosive water vapor, the gear surface is still good. Last month, we expanded the production line and ordered another batch of your gears. The packaging is still so solid. Each gear is wrapped separately with foam, and none of them were damaged during the long-distance transportation.Thank you very much for making such a good product. Now our factory's injection molding machines and mixers are all using your gears.

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Tel

+86-574-87168065

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Copyright © Raydafon Technology Group Co.,Limited All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |