QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

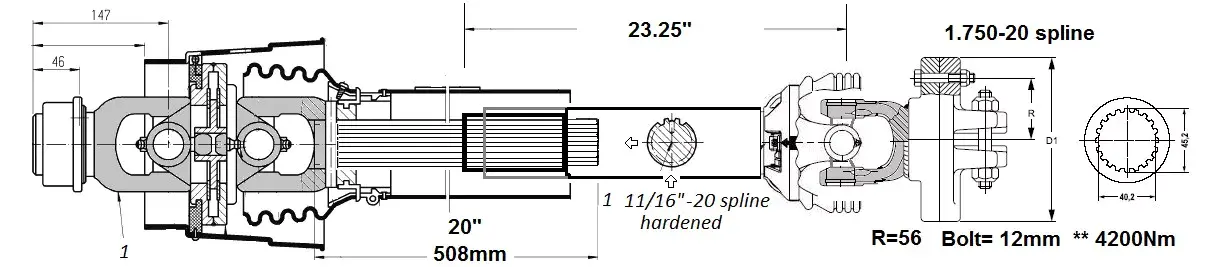

| 2580 series constant velocity | features |

| 1.375-21 CV Half Assembly #4GYM240 | Shield bearing #961-3525 |

| 1.750-20 CV Half Assembly #4GYM340 #93-26749 | KB61/20 2500 Series shear bolt assembly #4250105 |

1. Strengthen the transmission structure to adapt to high-horsepower operations

Raydafon's feed mixer power output shaft adopts a φ60mm thickened hexagonal tube + double-row needle bearing design, which is specially designed to cope with high-load mixing conditions. Actual test data shows that its torque carrying capacity reaches 3,500Nm, which is 40% higher than traditional products. It can stably drive 120-200 horsepower tractors and maintain speed fluctuations of less than 3% when crushing hard materials such as corn stalks and soybean meal. A Northeast ranch reported that after using this output shaft, the single batch feed processing capacity increased from 8 tons to 11 tons, and the failure rate of the mixer gearbox decreased by 65%, which completely solved the problem of broken shafts caused by high-power tractors matching small-size drive shafts.

2. Dynamic sealing technology to extend service life

For the dusty and humid environment of the ranch, the product innovatively adopts a three-lip sealing ring + dust cover combination structure. After running continuously for 500 hours in the sand and dust test, the internal cleanliness of the universal joint still reached the NAS level 6 standard. Its seal is made of fluororubber and polytetrafluoroethylene, with a temperature range of -40℃ to 120℃, and can keep the grease from solidifying in the environment of minus 35℃ in Inner Mongolia in winter. Actual measurements at an Australian ranch show that the service life of the output shaft is 12,000 hours, which is 2.3 times that of ordinary products, and the annual maintenance cost is reduced by about US$1,800.

3. Modular interface, compatible with global models

In order to solve the problem of interface differences between mixers of different brands, the product provides 12 flange hole distance specifications (adjustable from 110 to 190mm) and is equipped with a quick locking device, which shortens the installation time by 70% compared with the traditional welding type. The universal joint angle adjustment range is ±45°, and it can still transmit smoothly even when there is a 30cm height difference between the tractor and the mixer. A South American customer reported that by replacing the output shaft of Raydafon, three mixers of different brands in stock were successfully connected to the same power system, which increased the equipment utilization rate by 50% and saved 35% in procurement costs.

4. Lightweight design reduces energy consumption costs

On the premise of ensuring strength, the output shaft adopts high-strength aluminum alloy + hollow structure, which is 28% lighter than traditional steel products, reducing tractor fuel consumption by 8%-12%. A comparative test on a European ranch showed that a mixer equipped with this output shaft can save about 15 liters of diesel in 10 hours of operation per day, and reduce annual operating costs by 4,200 euros. In addition, its surface is hard anodized, and the friction coefficient is reduced to 0.15, further reducing energy loss, becoming the preferred solution for energy saving and efficiency improvement in ranches.

In large-scale pastures, Raydafon's PTO Shaft for Supreme Feed Mixers is widely used to drive TMR (total mixed ration) mixers. Its high torque characteristics can easily cope with the mixing needs of multiple components such as silage, hay, and concentrate. For example, a dairy farm with 10,000 cows has shortened the ration mixing time from 45 minutes to 28 minutes by equipping it with this output shaft, and the mixing uniformity has been increased to 96%, significantly reducing the risk of nutritional imbalance caused by picky eating of dairy cows. Its corrosion-resistant design is more suitable for the humid environment of the pasture. After three years of continuous use, the output shaft of a southern pasture still has no rust or oil leakage, becoming a core component for the pasture to improve feed conversion rate.

For small and medium-sized family farms, the modular design of the PTO shaft shows extremely high flexibility. Users can adapt to different brands of mixers by replacing the flange. For example, an Australian family farm used the same output shaft to connect three second-hand mixers in succession, successfully revitalizing idle equipment. Its lightweight structure (25% lighter than traditional models) reduces the power requirements for tractors, allowing 15-50 horsepower agricultural machinery to stably drive 1.5-3 cubic meter mixers, helping farmers save about 40% of equipment procurement costs while improving feed preparation efficiency.

In the field of biomass power generation, PTO shafts are used to drive straw crushing-mixing integrated equipment, and its ±40° universal joint adjustment capability can adapt to complex terrain operations. A northeastern biomass power plant reported that the output shaft can maintain a stable speed of 800-1,000rpm when processing materials such as corn straw and rice husks, and the uniformity of crushing particle size is improved by 30%, which directly reduces the coking rate of boiler combustion. Its high-strength design can withstand the impact of sand and stone in the material. A project test shows that the output shaft is still crack-free after 2,000 hours of continuous operation, which is twice as long as the life of traditional products.

In the event of natural disasters or sudden equipment failures, the plug-and-play characteristics of the PTO shaft become the key to ensuring feed supply. After a typhoon, a ranch restored the mixer in just 15 minutes by using Raydafon's spare output shaft, avoiding the risk of livestock running out of food. Its standardized interface design (ISO 5674 standard) is compatible with more than 90% of tractors worldwide. An international relief organization has included it in its emergency supplies list and successfully supported 12 post-disaster feed reconstruction projects in Africa, South America and other regions, becoming a "lifeline" component for the livestock industry.

I am Michael Rodriguez from Brazil. We purchased Raydafon's PTO Shaft for Supreme Feed Mixers for a large ranch in Sao Paulo State. After eight months of use, I was completely impressed by the product's performance. Under the extreme working conditions of mixing 20 tons of corn silage and soybean meal per day, the output shaft not only withstood the dust and high humidity environment, but also the torque stability reduced the mixer failure rate by 70% and increased the daily feed preparation efficiency by 25%. What was even more surprising was that your engineers took the initiative to provide customized flanges that perfectly fit the second-hand European mixers in our inventory, saving nearly $40,000 in equipment upgrade costs. From product quality to service response, Raydafon has changed my perception of Made in China. In the future, all ranch transmission parts will be given priority to you!

I am Daniel Carter from Australia. We purchased Raydafon's PTO Shaft for a 500-head beef cattle farm in New South Wales. After six months of use, it has completely exceeded our expectations - under the heavy operation of mixing 15 tons of hay and grain every day, the sealing performance of the output shaft ensures zero leakage of lubricating oil, the impact-resistant design of the universal joint withstands the bumps of the gravel road on the ranch, and the life of the mixer bearing is nearly doubled. From products to services, Raydafon has proven the reliability of Made in China with its strength, and we will definitely continue to choose you for future ranch expansion!

I am James Thompson. We upgraded the Raydafon PTO Shaft for the TMR mixer in Alberta Ranch. After using it for four months, we were completely amazed. In the extremely cold weather of -30℃, the antifreeze seal of the output shaft kept the grease fluid. When mixing 12 tons of wet corn stalks, the torque output was stable as before, and the equipment failure rate was directly reduced to zero. What's more considerate is that your technician took the initiative to guide us through video to adjust the transmission angle, so that the old tractor and the new mixer can be perfectly matched, and the daily feed preparation time is shortened by 2 hours. Looking forward to the next cooperation.

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Tel

+86-574-87168065

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Copyright © Raydafon Technology Group Co.,Limited All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |