QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

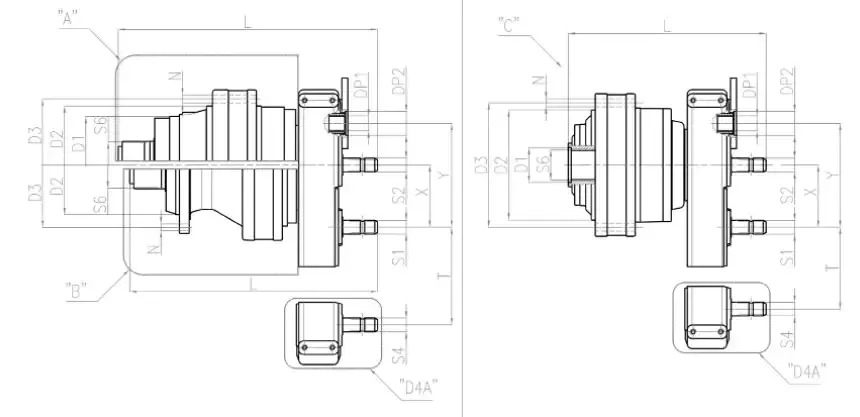

| Model | PG-702 | PG-1002 | PG-1602 | PG-1802 | PG-2502 | PG-3002 | PG-3503 | |||

| Ratio i | 18.2 | 18.3 | 13.4-33.6 | 15.7-29.9 | 14.6-20-36.2 | 45.3 | 53.7 | |||

| Output type | B | B | B | C | B | C | A | C | C | C |

| D1 |

|

|

|

88HB |

|

88HB | 245F7 | 102H7 | 102H7 | 122HF |

| D2 | 200F7 | 230F7 | 230F7 | 278F7 | 230F | 278F7 | 340F7 | 340F7 | 340F7 | 340F7 |

| D3 | 250 | 295 | 295 | 314 | 295 | 314 | 370 | 370 | 370 | 370 |

| N | ∅15×N°12 | ∅17×N°10 | ∅17×N°10 | ∅15×N°18 | ∅17×N°10 | ∅15×N°18 | ∅17×N°15 | ∅17×N°15 | ∅17×N°15 | ∅17×N°15 |

| L | 646.5 | 627.5 | 693 | 490.5 | 714 | 499.5 | 798.5 | 595.5 | 601 | 680.5 |

| S6 | 70*64 DIN5482 | 80*74 DIN5482 | 100*94 DIN5482 | 80*74 DIN5482 | 100*94 DIN5482 | 80*74 DIN5482 | 100*94 DIN5482 | 100*94 DIN5482 | 100*94 DIN5482 | 120*22*5 DIN5482 |

| S1 | 1" 3/8 Z6 | 1" 3/8 Z6 | 1" 3/8 Z6 | 1" 3/8 Z6 | 1" 3/8 Z6 | 1" 3/8 Z6 | 1" 3/8 Z6 | 1" 3/8 Z6 | 1" 3/8 Z6 | 1" 3/8 Z6 |

| S2 | 1" 3/8 Z6 | 1" 3/8 Z6 | 1" 3/8 Z6 | 1" 3/8 Z6 | 1" 3/8 Z6 | 1" 3/8 Z6 | 1" 3/8 Z6 |

|

|

|

| DP1 | 40*36 DIN5482 | 40*36 DIN5482 | 40*36 DIN5482 | 40*36 DIN5482 | 40*36 DIN5482 | 40*36 DIN5482 | 40*36 DIN5482 | 40*36 DIN5482 | 40*36 DIN5482 | 40*36 DIN5482 |

| DP2 | 60.3HB | 60.3HB | 60.3HB | 60.3HB | 60.3HB | 60.3HB | 60.3HB | 60.3HB | 60.3HB | 60.3HB |

| X | 157 | 157 | 157 | 157 | 157 | 157 | 157 | 157 | 157 | 157 |

| Y | 262 | 262 | 262 | 262 | 262 | 262 | 262 | 262 | 262 | 262 |

| S4 |

|

|

|

1" 3/8 Z6 |

|

1" 3/8 Z6 |

|

1" 3/8 Z6 | 1" 3/8 Z6 | 1" 3/8 Z6 |

| T |

|

|

|

156.8 |

|

156.8 |

|

156.8 | 156.8 | 156.8 |

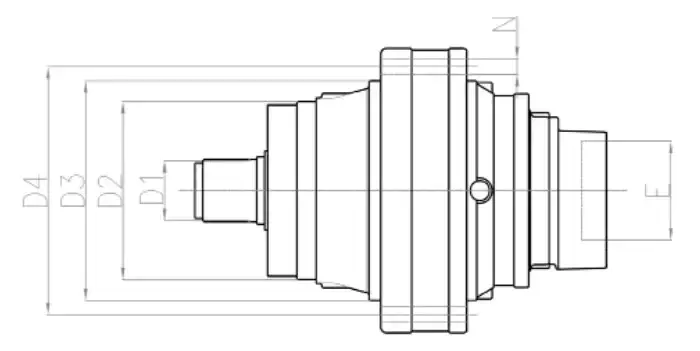

| Model | Ratio i | D1 | D2 | D3 | D4 | N | E |

| PG-1602 | 22.14-33.6 | 80*74 DIN5482 | 225 F7 | 278 F7 | 314 | ∅15×N°18 | SAE B/SAE C |

| PG-2502 | 20-36.2 | 100*94 DIN5482 | 245 F7 | 340F7 | 370 | ∅17×N°15 | SAE B/SAE C |

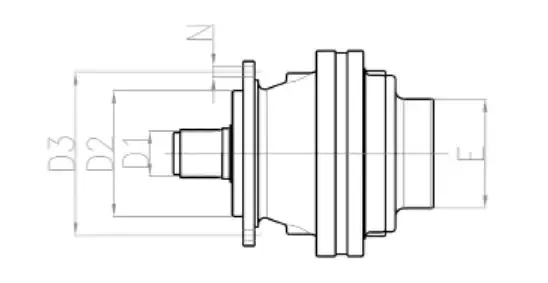

| Model | Ratio i | D1 | D2 | D3 | N | E |

| PG-161 | 3.55-2.49-5.60 | 40*36 DIN5482 | 110 F7 | 165 | ∅10.5×N°8 | SAE A/SAE B/SAE BB/OMTS |

| PG-251 | 4.13-5.17-6.00 | 58*53 DIN5482 | 150 F7 | 195 | ∅13×N°10 | SAE A/SAE B/SAE BB/OMTS |

| PG-501 | 4.13-5.17-6.00 | 58*53 DIN5482 | 150 F7 | 195 | ∅13×N°10 | SAE A/SAE B/SAE BB/OMTS |

The development of the PG series feed mixer planetary gearbox stems from a deep insight into the pain points of the transmission system of traditional mixing equipment. Its three planetary gear distributed transmission architecture is not a simple stacking of mechanical structures, but through repeated simulation of the stress conditions under different raw material ratios, the golden combination of gear modulus, tooth width and helix angle is finally determined. For example, when processing corn stalks and soybean meal mixtures, its unique involute tooth design can reduce the risk of material jamming by 15%. With the high-precision grinding process, the tooth surface roughness is controlled below Ra0.8, which increases the transmission efficiency by 8%-10% compared with traditional gearboxes. The measured data of a feed factory shows that in 12 hours of continuous operation per day, the energy consumption of this gearbox is 14% lower than that of similar products, and the torque fluctuation amplitude of the mixing shaft is reduced by 22%, which significantly improves the mixing uniformity.

For hard particles such as sand, stone, and metal debris that are often mixed in feed raw materials, this gearbox has been targeted in terms of materials and processes. The gear body is made of 20CrMnTi alloy steel. After quenching treatment with a carburizing depth of 1.2mm, combined with a low-temperature tempering process, the tooth root bending fatigue strength is increased to more than 850MPa. Under the extreme working conditions of incomplete raw material screening in a ranch, its pitting resistance has withstood a continuous 500-hour sand and gravel impact test, and only slight scratches appeared on the tooth surface without peeling. At the same time, by optimizing the rib plate layout and bearing preload of the planetary carrier, the gearbox can still maintain transmission accuracy when subjected to an instantaneous impact of 1.5 times the rated torque, avoiding the risk of gear misalignment or tooth breakage caused by overload.

The intelligent design of the gearbox is derived from a deep understanding of the pain points of operation and maintenance in the feed processing industry. Its built-in intelligent monitoring module is not a simple data collector, but a cross-analysis of temperature, vibration, current and other signals through an algorithm model. For example, when the bearing temperature is detected to be abnormally high, the system will combine the load history data to determine whether it is insufficient lubrication or bearing wear, and push specific maintenance recommendations. After applying this system, a feed company avoided three unplanned downtimes by replacing grease and adjusting bearing clearance in advance, and the overall equipment efficiency (OEE) increased by 18%. In addition, the design of its modular quick-release structure was inspired by the feedback of front-line maintenance personnel. Only four bolts need to be loosened to complete the overall replacement of the planetary gear set, and the maintenance time is shortened from 4 hours of the traditional structure to 1.5 hours.

In terms of environmental protection and energy efficiency optimization, the innovative design of the gearbox stems from the precise grasp of the needs of the feed industry to reduce costs and increase efficiency. Its heat dissipation structure does not blindly increase the heat dissipation area, but optimizes the spiral angle and spacing of the heat dissipation ribs through fluid mechanics simulation, so that the natural heat dissipation efficiency is increased by 30%, thereby reducing the energy consumption of the cooling fan. In the lubrication system, dual-zone oil supply technology is adopted to dynamically adjust the oil volume according to the load, avoiding the "flooding" lubrication method of traditional gearboxes, and reducing lubricant consumption by 25%. The actual measurement of a feed production line exported to Europe shows that the noise level of the gearbox is 5dB lower than the EU standard, and its energy efficiency level reaches the IE3 standard, helping customers to successfully pass the energy efficiency certification of the importing country. This design concept that deeply binds technical details with commercial value is the key to the product winning market recognition.

Hello! I am Elena García, a customer from Barcelona, Spain. We have been using your planetary gearbox in our photovoltaic panel tracking system for one and a half years. This equipment has completely solved our problem of sunshine tracking accuracy - the gearbox we used before always had a tracking deviation of about 5 degrees every morning and evening, while your planetary gearbox with encoder can control the tracking error within 0.5 degrees. Now the average daily power generation of photovoltaic panels has increased by 18% compared with before, and even the electricity bill has become significantly thinner. Now this planetary gearbox has withstood the test of salt spray and strong winds in the photovoltaic power station on the seaside. The anti-corrosion coating of the gearbox housing has not shown any signs of falling off, and the internal gear oil does not need to be replaced as frequently as before. I look forward to working with you in more renewable energy projects in the future!

I am Hans Müller, a mechanical engineer from Germany. Half a year ago, I purchased Raydafon's planetary gearboxes for production line upgrades. After using them, they exceeded my expectations! The equipment runs at high load for 16 hours a day to process high-viscosity raw materials. The gearbox noise is reduced by 20%, the transmission efficiency is stable at more than 94%, the temperature rise is always controlled within 25°C, and the durability is far superior to the old models. Your team was professional and efficient throughout the process, from early parameter optimization, sealing structure adjustment to remote debugging guidance. The detailed design (such as dustproof seals and standardized mounting holes) further reflects a deep understanding of the actual working conditions. Raydafon's product quality and service level made me include it in the list of long-term suppliers without hesitation, and strongly recommend it to my peers!

I have been running a ranch for so many years and have changed many gearboxes. It was not until I used Raydafon's planetary gearbox that I really realized what it means to be worry-free! The equipment I used before was always underpowered when mixing silage, and the gears often slipped. I didn't expect your planetary gearbox to be so powerful. Your product is much simpler to install than I thought, and it is also easy to maintain. Last time I did a daily inspection myself, I found that the gearbox was very well sealed and there was no sign of oil leakage at all. I will definitely continue to support you in the future and recommend you to my rancher friends! ----Mark Johnson

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Tel

+86-574-87168065

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Copyright © Raydafon Technology Group Co.,Limited All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |