QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Power "relay race": Feed Mixer Gearbox is like a "relay captain" for power transmission. After the motor is started, the power is first transmitted to the input shaft of the gearbox, and then "speed change" is achieved through the meshing of a group of gears of different sizes in the box. For example, if the input shaft rotates 1000 times per minute, the output shaft may only rotate 100 times after the gear group transmission, but the torque is greatly enhanced. This strong power is then transmitted to the mixing shaft, allowing the mixing blades to quickly stir the feed, easily dealing with "hard goods" such as high-fiber forage.

Precise meshing, reduced loss: The gears in the gearbox are not matched randomly. The gears produced by Raydafon have a tooth shape that has been precisely calculated and processed, and fit tightly when meshing, like two pieces of a puzzle that fit together perfectly. In this way, there is very little friction during power transmission, less energy loss, and most of the power can be used for mixing. It's like installing an "energy-saving core" on the feed mixer, which makes work more energetic without wasting energy.

Flexible adjustment to meet needs: Different feeds and different mixing amounts require different speeds. The beauty of the Feed Mixer Gearbox is that it can be adjusted flexibly. By changing the combination of gear sets, different speed ratios can be achieved to meet diverse needs. If you want to mix silage and concentrate quickly, increase the speed; if you want to handle fragile raw materials, lower the speed and mix slowly, and a gearbox can do it all.

Stable support and durability: The gearbox body is equivalent to the "guardian" of the entire transmission system. High-strength cast iron material, strong and shock-resistant, can stably support the internal gears and bearings. The internal bearings are specially lubricated for smooth rotation and reduced wear. Even if vibrations are generated during feed mixing, the gearbox can ensure stable engagement of the gears, continuously output stable power, and extend the overall service life.

Raydafon's product production process has been strictly tested and can be fully operational after actual installation. Choosing our products means you have chosen peace of mind.

| Ratio |

Input r.p.m |

Input Power | Output | Model | Comments | |

| Kw | HP | Nm | ||||

| 16.1:1 | 540 | 44.7 | 60 | 11600 | G1-0314 |

|

| 19.4:1 | 540 | 26.1 | 35 | 8600 | G1-0514 |

|

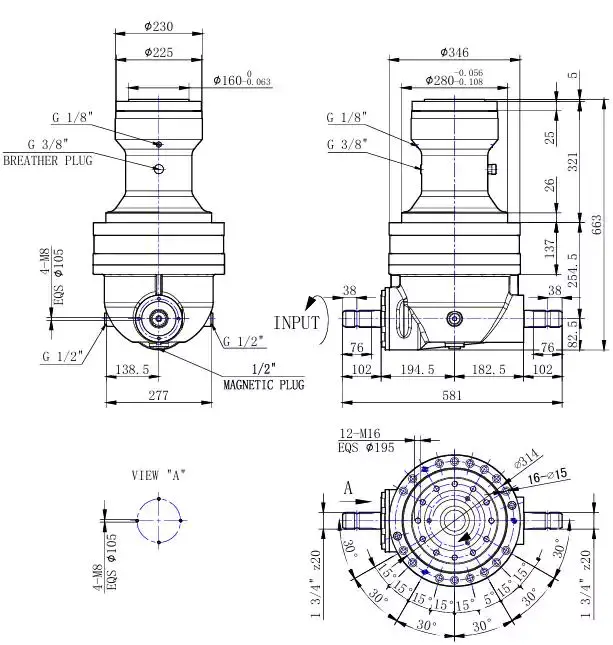

| Number | A | B | C | D | E | F | G | H | 1 | J | K | L | M | N | ||||||||||||||||||

| 1 | ⌀200 h7 | ⌀278 | 12-M16 EQS⌀245 | 15 | 25 | ⌀280 f7 | ⌀380 | 12-M16 |

|

26 | 30 | 353 | 300 | 785 | ||||||||||||||||||

| 2 | ⌀200 h7 | ⌀278 | 12-M16 EQS⌀245 | 15 | 25 | ⌀280 f7 | ⌀380 | 12-M16 |

|

26 | 30 | 353 | 402.5 | 857.5 | ||||||||||||||||||

| 3 | ⌀278 h8 | ⌀345 | 15-M16 EQS⌀314 | 8 | 25 | ⌀348 h8 | ⌀385 | 12-⌀17 | 2-M18 | 10.5 | 29 | 351 | 321.5 | 774.5 | ||||||||||||||||||

| 4 | ⌀278 h8 | ⌀345 | 15-M16 EQS⌀314 | 8 | 25 | ⌀348 h8 | ⌀385 | 12-⌀17 | 2-M18 | 10.5 | 29 | 351 | 394 | 847 | ||||||||||||||||||

| 5 | ⌀154.8 h8 | ⌀250 | 12-M20*1.5 EQS⌀205 | 12 | 39 | ⌀348 h8 | ⌀385 | 12-⌀17 | 2-M18 | 10.5 | 29 | 354.5 | 321.5 | 778 | ||||||||||||||||||

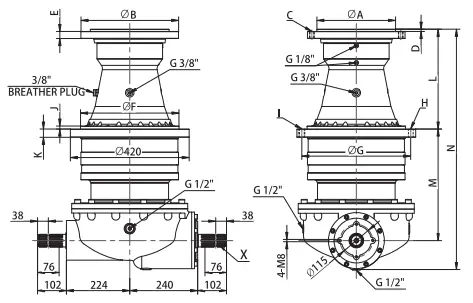

| Ratio |

lnput r.p.m |

Input Power |

Output Nm |

Input Shaft | Comments | |||||||||||||||||||||||||||

| kW | HP | |||||||||||||||||||||||||||||||

| 13.4:1 | 540 | 85.8 | 115 | 17984 | X |

|

||||||||||||||||||||||||||

| 14.6:1 | 540 | 70.8 | 95 | 16187 | X |

|

||||||||||||||||||||||||||

| 16.1:1 | 540 | 63.4 | 85 | 15971 | X |

|

||||||||||||||||||||||||||

| 18.2:1 | 540 | 44.7 | 60 | 12744 | X |

|

||||||||||||||||||||||||||

| 21.1:1 | 540 | 37.3 | 50 | 12312 | X |

|

||||||||||||||||||||||||||

| 25.9:1 | 1000 | 82 | 110 | 17954 | X |

|

||||||||||||||||||||||||||

| 28.3:1 | 1000 | 67.1 | 90 | 16051 | X |

|

||||||||||||||||||||||||||

Steel "body" is super durable: This gearbox is made of thickened high-strength cast iron, and the entire box is as strong as a tank shell. Whether it is the humid environment when mixing silage or the violent vibration caused by handling pelletized feed, it can withstand it steadily. The internal gears are carburized and quenched, and the tooth surface hardness is as high as HRC58. The wear resistance is 3 times stronger than ordinary gears. It has been used continuously for five or six years in dusty and heavy-loaded farms, and the performance is still "online", and the number of repairs is very few.

Power transmission "zero waste": The design is full of ingenuity! The gear meshing accuracy reaches the hair level, and the power transmission efficiency exceeds 95%. Other gearboxes may have a lot of power "slipping away" during mixing, but our Feed Mixer Gearbox for TMR Mixer EP RMG can use all the power of the motor on the blade. For the same mixing of 5 tons of feed, using our gearbox can be 15 minutes faster and save 20% of electricity bills, saving farmers real money.

"Universal adaptability" is super worry-free: Whether it is a simple mixer in a small farm or a giant equipment in a large feed factory, this gearbox can be seamlessly connected. The speed ratio can be freely adjusted from 2:1 to 15:1, and roughage, concentrate feed, and mixed feed can be mixed however you want. Installation is also easy, and there is no need to make major changes to the equipment. Ordinary workers can get it done in half an hour according to the instructions, which is especially suitable for farmers who are in a hurry. "Intelligent protection" is super considerate: The gearbox has a built-in overload protection device. Once the mixing load is too large, it will automatically "stop" to avoid damage to the gears, which not only protects the machine but also prevents safety accidents. Moreover, the structural design is reasonable. You can change a bearing or repair a gear by opening the box. It is not as troublesome as dismantling a "Russian doll". The downtime and maintenance time is greatly shortened, ensuring that the farm production does not stop.

As an overseas customer, I really want to say thank you to Raydafon! Your feed mixer gearbox is really easy to use. Since it was installed, the equipment has been running very smoothly, and the working efficiency is much higher than before. The gearbox is made of solid and durable materials, and it is easy to install and maintain. It has solved the old problems we had on our previous equipment. I have to praise the after-sales service in particular. We encountered some small questions when using it, and you quickly figured it out. It is very reliable. This cooperation experience is really good. I have recommended your products to my peers, and I look forward to continuing cooperation in the future! -----James Carter

Hey, I'm David Johnson, a customer of Raydafon. I bought your Feed Mixer Gearboxes before, and it's really great to use! After installing this gearbox, our feed mixer runs much smoother than before, and the efficiency has been improved. I used to worry about the equipment jamming, but now I don't have to worry about it at all. What makes me feel most worthwhile is that it is very durable, the material feels solid, and it is not troublesome to maintain it on a daily basis. Just tighten a few screws and check the oil level, unlike the previous equipment that needs to be tossed every few days. Last time I had some small questions when operating here, I sent an email to your after-sales service, and received a reply on the same day. The engineer also drew a schematic diagram to teach me how to adjust it. This service is great! To be honest, I often talk about your products with my colleagues when I have dinner together. Good things should be known to more people. I hope to continue to cooperate with you in the future, and I wish your business will become more and more popular!

My name is Michael Brown. I was a little hesitant when I first bought your Feed Mixer Gearboxes, after all, I was cheated by other products before, but after using it for almost half a year, I really give it a thumbs up! The noise of this gearbox is much smaller than before. Before, it was like thunder when it was turned on, but now I don’t need to shout when talking in the workshop. The most surprising thing is the efficiency. It used to take 40 minutes to mix a batch of feed, but now it can be done in 25 minutes, and the conveyor belt has also increased its speed. Last week, the indicator light of the gearbox flashed twice. I wondered if there was a problem, so I called your after-sales service. The girl who answered the phone was very patient. She let me take a few photos and guided me to clean the dust from the sensor on the spot. It took no more than 10 minutes. The gearbox is made of solid materials. The outer shell feels heavy. Last time, a forklift accidentally rubbed it, leaving a little mark, but the parts inside were not affected. I kept talking about your products when I was drinking with the farmer next door. He also plans to order one next month! I look forward to trying your new accessories in the future, and I wish you get stronger and stronger!

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Tel

+86-574-87168065

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Copyright © Raydafon Technology Group Co.,Limited All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |