QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

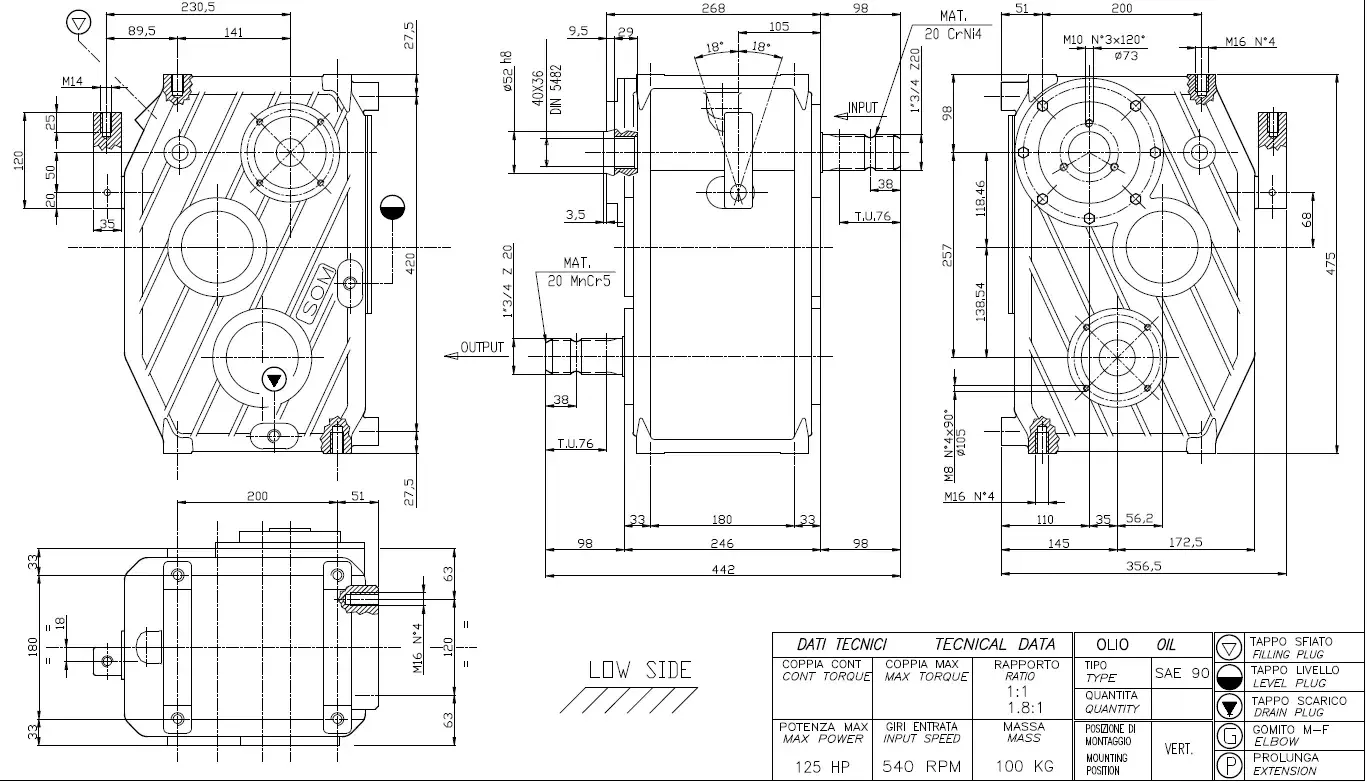

| Product Name | Feed Mixer Gearboxes - Replacement of Comer C3A, 1:1, 1, 8:1 |

| Unit | Each |

| Product details | Housing material: cast iron Contact us for power at a different RPM The gearbox is delivered without oil and must be filled before first use. First oil change after 50-70 operating hours, then after 500-700 operating hours or at least once a year. |

| Application range | Mixing wagon |

| Model | C3A |

| Max. input rotation speed | 540 r/min |

| Consists of | Gearbox Order oil separately |

| Max. input power | 92 kW |

| Connection 1 type | Splined |

| Connection 1 outside diameter | 1-3/4 Inch |

| Connection 1 number of splines | 20 |

| Connection 2 type | Splined |

| Connection 2 outside diameter | 1-3/4 Inch |

| Connection 2 number of splines | 20 |

| Suitable for machine/vehicle brand | Aksa DAF Agro Falke Maschinenbau Euromilk Metal-Fach |

| Contains oil | No |

| Oil SAE viscosity grade | 90 |

In today's booming modern animal husbandry, the Comer Replacement Feed Mixer Gearbox has long become the "behind-the-scenes hero" in the farm. Entering the large-scale breeding base, the efficiency and quality of the feed mixing process are largely controlled by this equipment. It is like the "power heart" of the feed mixer, accurately driving the blades to fully mix hay, grains, silage and other raw materials, so that every bite of feed eaten by livestock is full of balanced nutrition, laying a solid foundation for the healthy growth of animals.

Although the appearance of this gearbox is inconspicuous, its working principle is hidden. Through the precisely meshed gear set, the strong power of the motor is efficiently transmitted to the mixing blades, driving the blades to continuously flip, cut and mix the feed. In view of the different characteristics of hay fluffy and wet feed sticky, the gearbox can also flexibly adjust the speed, whether it is gently turning the hay or forcefully breaking up the lumps of wet feed, it can easily do the job.

In actual use, the benefits brought by the feed mixer gearboxes are visible to the naked eye. In the past, when mixing manually, problems such as feed stratification and agglomeration often occurred. Now, with mechanical mixing driven by a gearbox, the ratio of each spoonful of feed is accurate, the livestock eat well, grow strong, and the market cycle is significantly shortened. Moreover, automated mixing replaces heavy physical labor, which not only saves a lot of labor costs, but also greatly improves work efficiency. High-quality gearboxes are made of wear-resistant materials, and daily maintenance is simple. Even if there are occasional failures, the maintenance cost is very affordable, and the long-term use is extremely cost-effective.

In the transition from traditional farming to smart ranches, feed mixer gearboxes have always been a key link in improving farming benefits. It optimizes feed quality with stable performance and liberates manpower with automated operation. With the iteration and upgrading of technology, it will surely create more value for animal husbandry in the future and become a reliable partner for farmers to increase production and income.

In the daily operation of the farm, the feed mixer gearbox is not a "small role". As the power core of agricultural machinery, it directly determines the efficiency and quality of feed mixing. Raydafon has been deeply engaged in gearbox manufacturing. Its Feed Mixer Gearbox has become the favorite of countless farmers with its solid performance.

Durable and durable, it does not "fall off the chain": this gearbox is made of high-strength steel, just like putting "armor" on the machine. Even if it runs continuously for 8 hours a day, it is as stable as Mount Tai when mixing high-fiber forage and wet grains. The surface of the gear has been specially quenched and has a high wear resistance. In a farm with dust and heavy water vapor, it does not need to be overhauled for three to five years, and the attendance rate is super high.

The power is "controlled" in place, saving electricity and time: the design emphasizes the word "smart", the gears are tightly engaged, and there is almost no loss in power transmission. Other mixers are still slowly "stirring" feed, but machines with Raydafon gearboxes can stir several tons of feed evenly and finely in half an hour. And the energy consumption is 20% lower than that of ordinary gearboxes. In the long run, the fuel and electricity costs alone can save a lot of money.

"Universal adaptation" does not pick and choose: whether it is a small mixer in a family farm or a giant mixing equipment in a large farm, this gearbox can "seamlessly connect". The speed ratio can be adjusted as needed, and you can mix concentrated feed, roughage, and even silage as you want. The installation is also simple, and there is no need to make major changes to the equipment. It can be used directly by replacing it, which is particularly worry-free.

Easy to repair and safe, and it is reliable to use: the gearbox structure does not have a complicated "flower frame". If any part is broken, the worker can take it down and replace it with a wrench, and production can be resumed in half a day. It also has intelligent protection. Once it is overloaded, it will automatically shut down immediately, which not only avoids the machine from being scrapped "hard", but also eliminates safety hazards, and it is very reliable to operate.

Raydafon's Feed Mixer Gearbox combines durability, efficiency, flexibility and safety, and can help farmers improve efficiency and reduce costs. It is a reliable "good helper" in modern agricultural production.

My name is Michael Thompson. I bought Feed Mixer Gearboxes from Raydafon and it is very smooth to use after installation. The product quality is very reliable, the operation is stable, the efficiency is high, and it is very labor-saving when working. Your service is also very good. I asked a lot of questions and the team answered them patiently. There was no barrier in communication. As an overseas customer, it is rare to meet such a solid supplier. I will contact you again when I need it in the future!

My name is David Wilson. I bought Feed Mixer Gearboxes from Raydafon and I feel very good after using them. The product is solidly made, and it runs very steadily after installing the equipment. It works efficiently and has basically no problems. The service of your team is also very reliable. I asked a lot of questions, and you answered them patiently with a very good attitude, which made me, a foreign customer, feel very at ease. I will continue to cooperate with you in the future!

I am Hannah Moore from New Zealand. I have changed several batches of feed mixer gearboxes in my past years of running a ranch. It was not until I used Raydafon's products that I realized what "worry-free" meant! I used to be most afraid of mixing wet materials. The old equipment would always get stuck, either the gears slipped or the motors overheated. Your Feed Mixer Gearboxes completely overturned my impression. When it comes to difficult raw materials such as silage and beet pulp, they are not only powerful, but also can intelligently adjust the speed, and the mixing efficiency is nearly twice as fast as before.

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Tel

+86-574-87168065

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Copyright © Raydafon Technology Group Co.,Limited All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |