QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

| Model: | EP-NRV-F 025, 030, 040, 050, 063, 075, 090, 110, 130, 150 |

| Ratio: | 1:5, 7.5, 10, 15, 20, 25, 30, 40, 50, 60, 80, 100 |

| Color: | Blue, Silver, or On Customer Request |

| Material: | Housing: Die-Cast Aluminum Alloy |

| Worm Gear: Bronze 94# | |

| Worm-20CrMnTi with carburizing and quenching, the surface harness is 56-62HRC | |

| Shaft-chromium steel 45# | |

| Packing: | Carton and plywood case |

| Bearing: | C&U Bearing |

| Seal: | NAK, SKF |

| Lubricant: | Synthetic, Mineral |

| Usages: | Industrial Machine: Food Stuff, Ceramics, Chemical, Packing, Dyeing, Woodworking, Glass, etc. |

| Warranty: | 12 months |

| Input Power: | 0.06kw, 0.09kw, 0.12kw, 0.18kw, 0.25kw, 0.37kw, 0.55kw, 0.75kw, 1.1kw, 1.5kw, 2.2kw, 3kw, 4kw, 5.5kw, 7.5kw, 11kw, 15kw |

| IEC Flange: | 56B5, 56B14, 63B5, 63B14, 71B5, 71B14, 80B5, 80B14, 90B5, 90B14, 100B5, 100B14, 112B5, 112B14, 132B5, 160B5 |

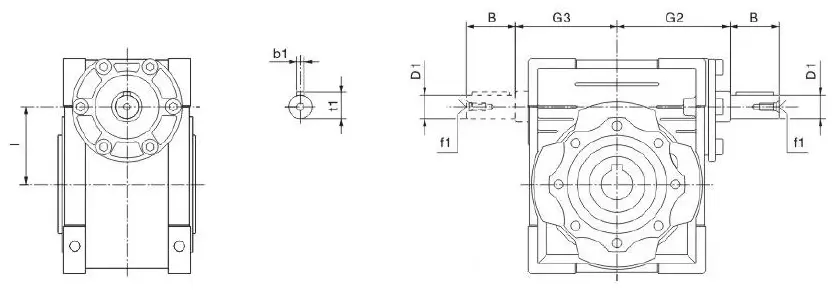

| NRV | 030 | 040 | 050 | 063 | 075 | 090 | 110 | 130 | 150 |

| B | 20 | 23 | 30 | 40 | 50 | 50 | 60 | 80 | 80 |

| D1 | 9j6 | 11 j6 | 14 j6 | 19j6 | 24j6 | 24j6 | 28j6 | 30 j6 | 35 j6 |

| G2 | 51 | 60 | 74 | 90 | 105 | 125 | 142 | 162 | 195 |

| G3 | 45 | 53 | 64 | 75 | 90 | 108 | 135 | 155 | 175 |

| I | 30 | 40 | 50 | 63 | 75 | 90 | 110 | 130 | 150 |

| b1 | 3 | 4 | 5 | 6 | 8 | 8 | 8 | 8 | 10 |

| f1 | - | - | M6 | M6 | M8 | M8 | M10 | M10 | M12 |

| t1 | 10.2 | 12.5 | 16 | 21.5 | 27 | 27 | 31 | 33 | 38 |

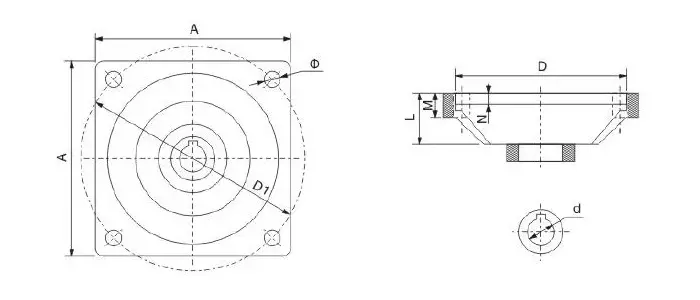

| Model | A | D | D1 | φ | d | L | M | N |

| 30 | 60*60 | 50 | 70 | M5 | φ11 | 20 | 20 | 4 |

| 80*80 | 70 | 92 | φ6.5 | φ11 | 21 | 10 | 4.5 | |

| 86*86 | 73 | 100 | φ6.5 | φ11 | 22 | 10 | 4.5 | |

| 90*90 | 83 | 104 | φ6.5 | φ11 | 23 | 10 | 5 | |

| 40 | 60*60 | 50 | 70 | M5 | φ14/Φ11 | 20 | 20 | 4 |

| 80*80 | 70 | 92 | φ6.5 | φ14/Φ11 | 21 | 10 | 4.5 | |

| 86*86 | 73 | 100 | φ6.5 | φ12.7/Φ14 | 22 | 10 | 4.5 | |

| 90*90 | 83 | 104 | φ6.5 | φ11 | 23 | 10 | 5 | |

| 104*104 | 94 | 120 | φ8.5 | φ14 | 23 | 10 | 5 | |

| 50 | 80*80 | 70 | 92 | φ6.5 | φ14/Φ11 | 21 | 10 | 4.5 |

| 86*86 | 73 | 100 | φ6.5 | φ14/Φ12.7 | 22 | 10 | 4.5 | |

| 90*90 | 83 | 104 | φ6.5 | φ11 | 22 | 10 | 5 | |

| 104*104 | 94 | 120 | φ8.5 | φ14 | 23 | 10 | 5 | |

| 110*110 | 85/95 | 132 | φ8.5 | φ19 | 22 | 12 | 6 | |

| 130*130 | 100/110 | 145 | φ8.5 | φ19 | 25 | 12 | 6 | |

| 63 | 80*80 | 70 | 92 | φ6.5 | φ19 | 25 | 25 | 6 |

| 86*86 | 73 | 100 | φ6.5 | φ12.7 | 25 | 25 | 6 | |

| 110*110 | 85/95 | 132 | φ8.5 | φ19 | 22 | 1 | 6 | |

| 130*130 | 100/110 | 145 | φ8.5 | φ22/①24 | 33 | 12 | 6 | |

| 75/90 | 110*110 | 85/95 | 132 | φ8.5 | φ19 | 40 | 1 | 6 |

| 130*130 | 100/110 | 145 | φ8.5 | φ22/φ24 | 33 | 12 | 6 |

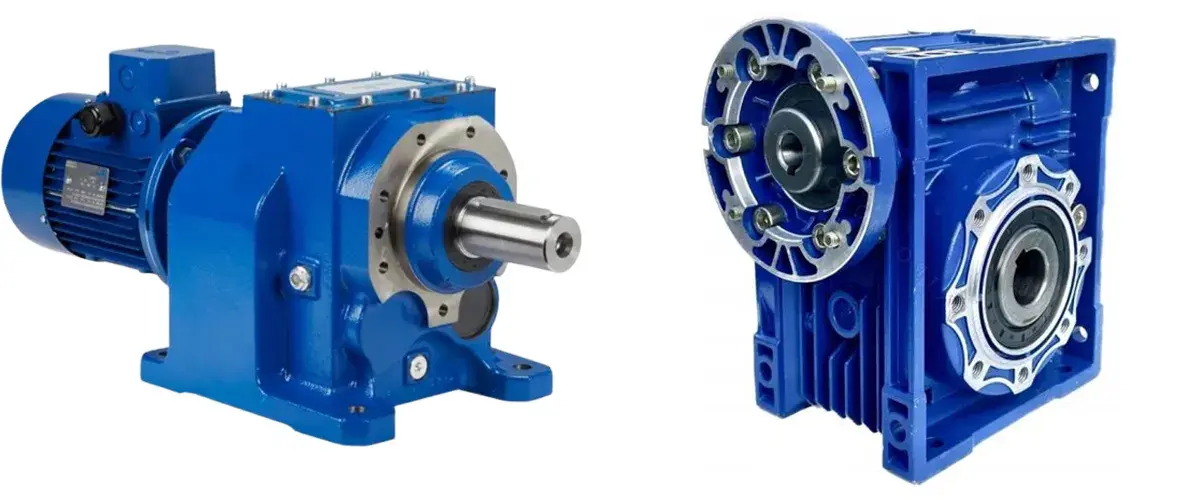

Compact layout, suitable for small space: EP-NRV-F Single Solid Shaft Input Worm Gearbox adopts single solid shaft input design, and the structure abandons the redundant components of traditional reducer, and the overall volume is greatly reduced, which is particularly suitable for installation in machine tools, conveyor lines and other space-constrained scenes. The meshing angle between the worm and the worm wheel has been repeatedly optimized, and the transmission efficiency is about 12% higher than that of ordinary models. At the same time, the operating noise is reduced to below 65 decibels, and it will not interfere with the workshop environment even if it runs for a long time. The cast iron shell is rust-proofed, and the surface coating can resist acid and alkali environment corrosion, and it can still operate stably in humid or dusty factories.

Wide torque coverage and wide adaptability: The reducer provides reduction ratio options from 7.5:1 to 100:1, and the output torque range covers 10Nm to 1800Nm, which can flexibly match the power requirements of different equipment. For example, in automated packaging equipment, low reduction ratio models can drive high-speed sealing mechanisms; while in mining crushers, high reduction ratio models can provide continuous and stable heavy-duty torque. The gear adopts carburizing and quenching process, and the tooth surface hardness reaches HRC58-62. Even in the face of frequent start-stop or impact load, it can maintain transmission accuracy and reduce downtime and maintenance caused by gear wear.

Tight protection and reduced maintenance costs: The shell design with IP55 protection level allows the EP-NRV-F reducer to operate reliably under harsh working conditions such as dust and water mist. The sealing ring is made of high-temperature resistant fluororubber, which will not age and crack even if exposed to 80℃ high temperature environment for a long time. The internal lubrication system ensures that the lubricating oil is always in the best condition through the oil level observation window and automatic oil filling device. The user only needs to check the oil quality once every 6 months. Compared with the maintenance frequency of traditional reducers that need to replace lubricating oil 2-3 times a year, this product can save about 40% of maintenance costs.

Flexible customization and outstanding cost-effectiveness: Raydafon provides customized services for EP-NRV-F reducers according to different needs of customers, such as adjusting the output shaft diameter, adding flange interfaces or integrating electromagnetic brakes. In the case of a food processing plant, the customer required a reducer to be directly connected to an imported servo motor. Raydafon achieved seamless connection by optimizing the input shaft size and keyway design, avoiding the purchase cost of additional adapters. Compared with similar imported brand products, the price of EP-NRV-F is about 30% lower, and the delivery cycle is shortened to 15 days, making it the first choice for small and medium-sized enterprises to upgrade their equipment.

The main idea behind the EP-NRV-F reducer is to use the worm and worm wheel's helical meshing to change power. The motor turns the single solid shaft, which in turn turns the worm wheel. The worm wheel turns because of the helical tooth surface on the worm. The high-speed input is changed into a low-speed, high-torque output by changing the helix angle and the number of teeth ratio. For instance, when moving materials, the motor speed can be as high as 3000 rpm. But after going through the reducer, the output speed can be lowered to 30 rpm, and the torque can be increased to 100 times the original, which makes it easy to move a heavy-loaded roller or chain. This way of sending things has a self-locking feature. The worm wheel won't turn the other way even when the equipment is off because of load inertia, which keeps safety performance high.

The worm has a helical tooth structure, and the way the tooth surface and worm wheel touch each other has changed from "single-point friction" to "multi-point rolling." After the contact area is increased, the unit pressure drops by about 30%, which greatly cuts down on gear wear and heating problems. Tests done at a machinery plant show that after 8 hours of continuous use, the helical gear reducer's surface temperature is 15°C lower than that of the straight tooth model, and the noise level is 10 decibels lower. This design is especially good for situations where quietness is very important, like food packaging lines or medical equipment. It can not only keep noise from getting in the way of workers, but it can also make gears last longer.

The reducer uses both oil pool lubrication and splash lubrication. When the worm turns, the oil is thrown into the meshing area, where it forms a moving oil film that keeps the metal from touching each other directly. The shell has fins and slots for ventilation that help it lose heat. The internal temperature can be kept below 60°C by circulating lubricating oil. For instance, mining machines must work nonstop for 24 hours a day. Because of the high temperature, regular reducers can turn lubricating oil into carbon. EP-NRV-F can avoid these kinds of problems by using a heat dissipation design that keeps the gearbox efficiency stable at over 95%.

The EP-NRV-F reducer can be customised in a modular way. Users can choose the reduction ratio, the shape of the output shaft (solid or hollow), or the way to install it (foot installation or flange installation) that works best for them. When a textile factory got new machines, it had to connect the reducer directly to the imported servo motor, but the size of the motor output shaft didn't match the standard model. Raydafon was able to do custom production in just three days by changing the diameter of the input shaft and the position of the keyway. This saved them the cost of replacing the whole gearbox system. This flexibility makes it perfect for changing old machines or making new production lines.

I am David Parker from the UK. I have been using your worm gearbox in my machining shop in Birmingham for almost two years. It is getting better and better. When I changed the equipment, I was just giving it a try. I didn’t expect that it completely solved the old problem of high heat generation and harsh noise of the metal gearbox. The heat dissipation ribs of your box are very reasonable. The shell is only slightly warm after 12 hours of continuous operation. The noise of gear meshing is at least 15 decibels lower than that of the original equipment. Workers finally don’t need to wear earplugs when operating. Now this gearbox drives our heavy-duty stamping equipment. Even the 400kg mold can be raised and lowered without any jamming. The self-locking function firmly locks the slider when the power is off. We have never worried about safety. I really like your products and services. Raydafon will be given priority for the next batch of equipment upgrades!

I am Sarah Johnson, a Canadian customer. I have been using your worm gearbox on my farm in Manitoba for more than a year. I have to praise this product. The previous gearbox broke down in the winter, and the gears kept slipping in the low temperature. I didn't expect your gearbox to run smoothly in a -20 degree environment. The planter didn't fall off the chain during the whole winter last year. The weather resistance is really amazing. Now several equipments on our farm use Raydafon gearboxes, and the quality has never disappointed us. I have recommended you to the local agricultural cooperatives, and everyone said that they are safe to use. I wish your business will get better and better, and I will buy from you again in the future if I need it!

I am Michael Thompson, and I work for a small company in the US that makes automation equipment. I bought a set of worm gear reducers from Raydafon not long ago, and I'm very happy with how they work! We have always used European brand reducers, but the delivery time is long, the price is high, and the response time after the sale is slow. This time I tried Raydafon's products and found that they are just as good as European brands, and they even work better at controlling noise and getting rid of heat. Your technical team was especially helpful during the selection process by suggesting the best model for our working conditions and making custom installation dimension drawings for us. This saved us a lot of trouble. We will definitely keep buying Raydafon's products and telling our friends about them in the future! I hope you can keep up the good work and service, and I look forward to working with you for a long time!

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Tel

+86-574-87168065

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Copyright © Raydafon Technology Group Co.,Limited All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |