QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

The Raydafon EP-FT800.55A.012 Hydraulic Lift Cylinder isn’t just another part—it’s a solution built to last, made for jobs where reliability and staying power matter most. With a 100mm bore that strikes the right balance, this cylinder packs enough strength without being bulky, making it a solid fit for all kinds of setups. Every choice, from the materials we pick to the all-welded build, is intentional: we want to cut down on downtime, keep maintenance costs low, and make sure over time, this cylinder doesn’t just work—it saves you money, too.

Take the design philosophy, for example. Strength is key here. The all-welded body skips those tie-rods that often fail when things get busy—think high-cycle machines or places with lots of vibration. That means fewer breakdowns, even when it’s running hard, whether it’s acting as a heavy-duty hydraulic lift cylinder in construction gear or a steady performer in agricultural equipment.

Then there’s the sealing system. We went with a multi-stage setup that’s tough enough to handle sudden pressure spikes and keep gunk out. No leaks, no mess, just consistent performance. That’s a big deal when you’re relying on it as a telescopic hydraulic lift cylinder in tight spaces or a daily workhorse in industrial lifts—you need it to hold up, day in and day out.

And let’s talk materials. We use high-tensile steel that’s induction-hardened and chrome-plated, so it can take a beating from wear and rust. Whether it’s exposed to mud on a farm, rain on a construction site, or the grit of a warehouse, this cylinder stays strong. It’s the kind of durability you need from a hydraulic lift cylinder that’s meant to be in it for the long haul.

The standard configuration of our EP-FT800.55A.012 offers exceptional performance and quality right out of the box, serving as the proven platform for all custom variants.

| Parameter | Specification |

| Model Number | EP-FT800.55A.012 |

| Bore Diameter | 80 mm |

| Rod Diameter | 32 mm |

| Stroke Length | 200 mm |

| Installation | 535 mm (Retracted, center-to-center) |

| Construction | Heavy-Duty Welded Body |

| Pressure Rating | 210 Bar (3045 PSI) Rated |

| Standard Port Type | (Specify standard, e.g., #8 SAE O-Ring Boss) |

| Standard Mounting | (Specify standard, e.g., Welded Cross-Tube Ends) |

Your hydraulic cylinder should be too. At Shandong Everpower, we specialize in partnering with OEMs and end-users to modify the EP-FT800.55A.012 platform to your exact specifications. Our streamlined process makes it easy to get the perfect cylinder for your application.

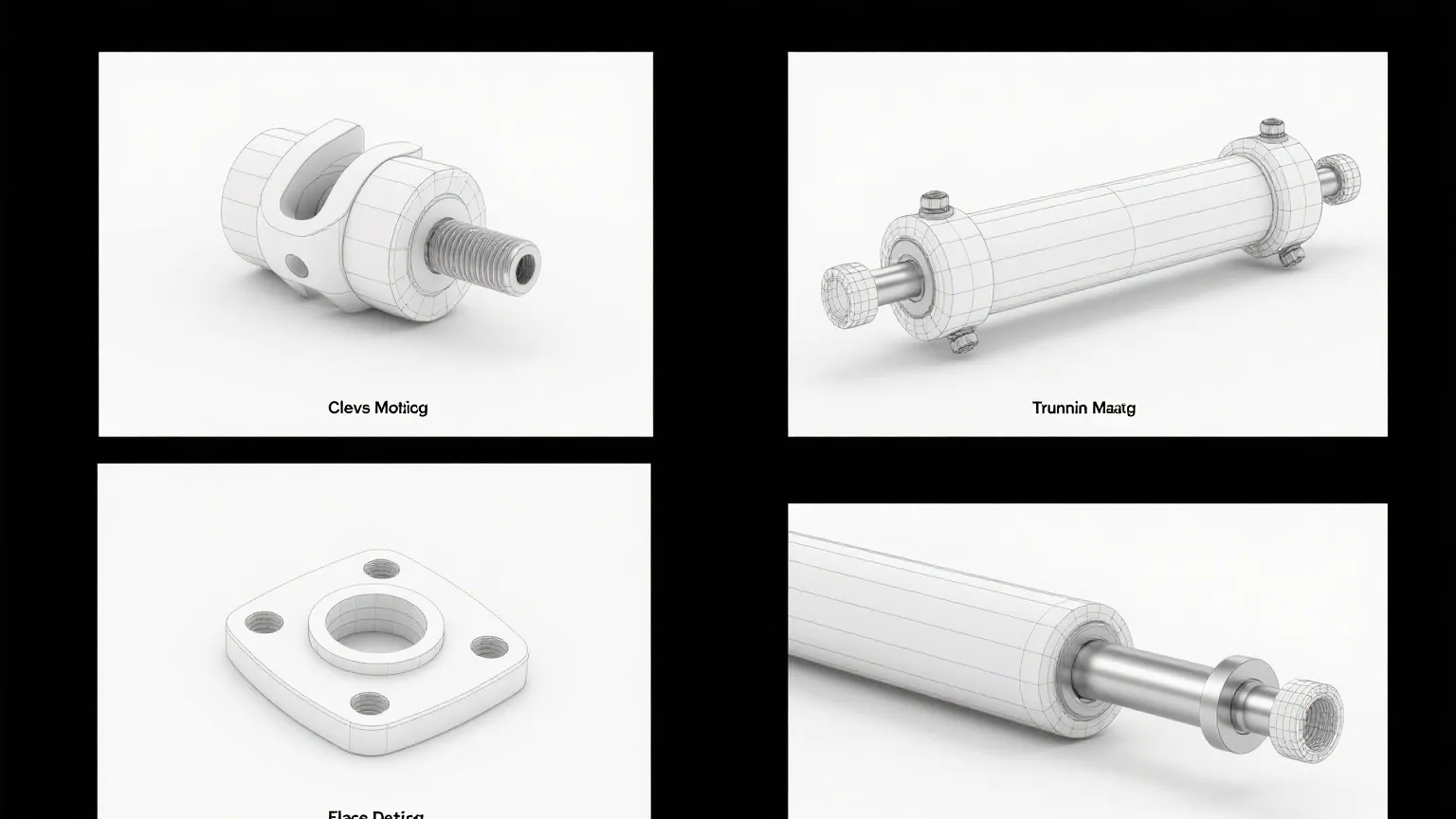

Step 1: Select Your Mounting Style

The way a cylinder is mounted is critical for proper force transfer and longevity. We offer a wide range of mounting options beyond the standard cross-tube.

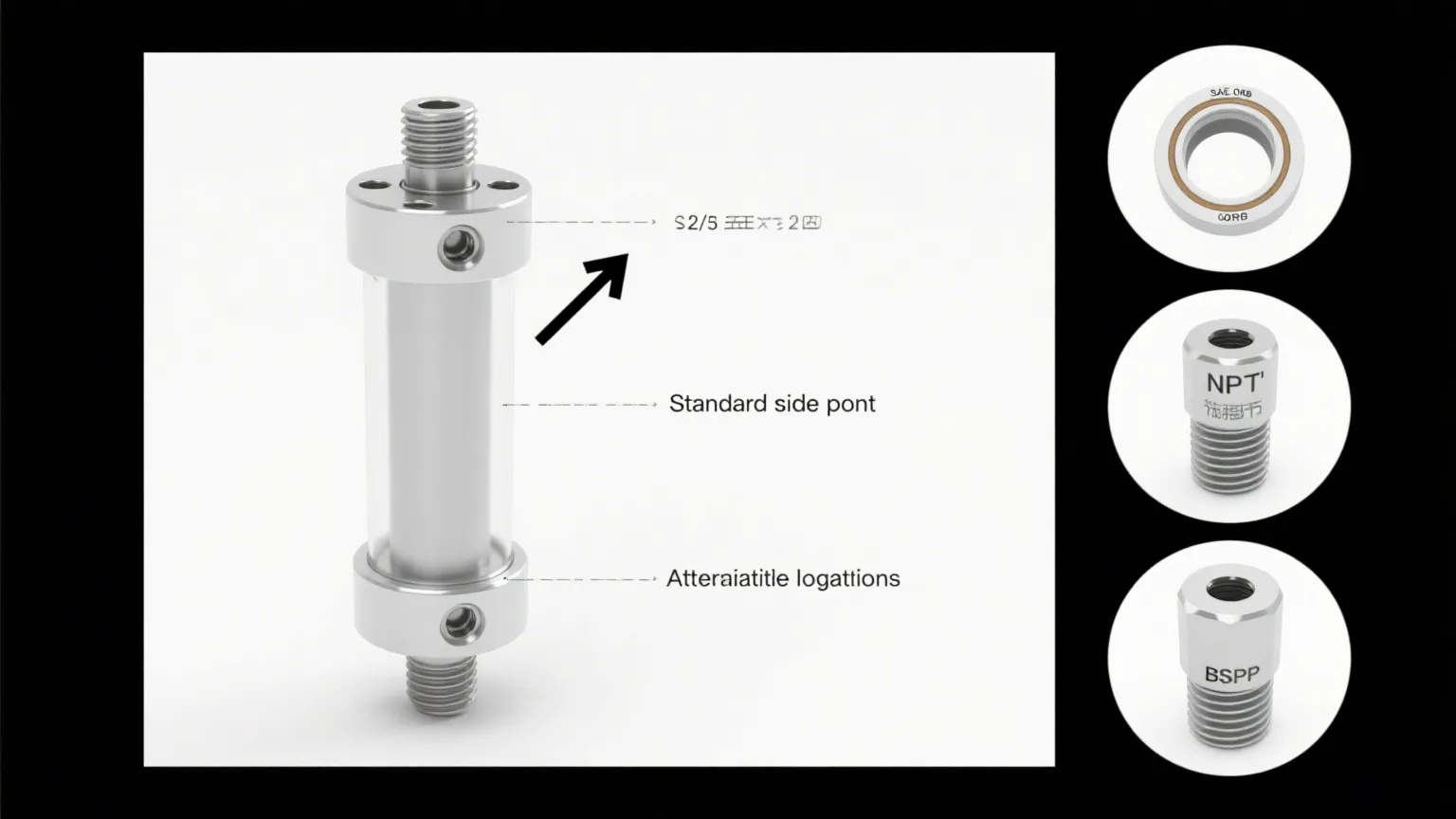

Step 2: Configure Port Type and Location

Proper fluid delivery is key to efficiency. We can configure ports to match your existing plumbing and space constraints.

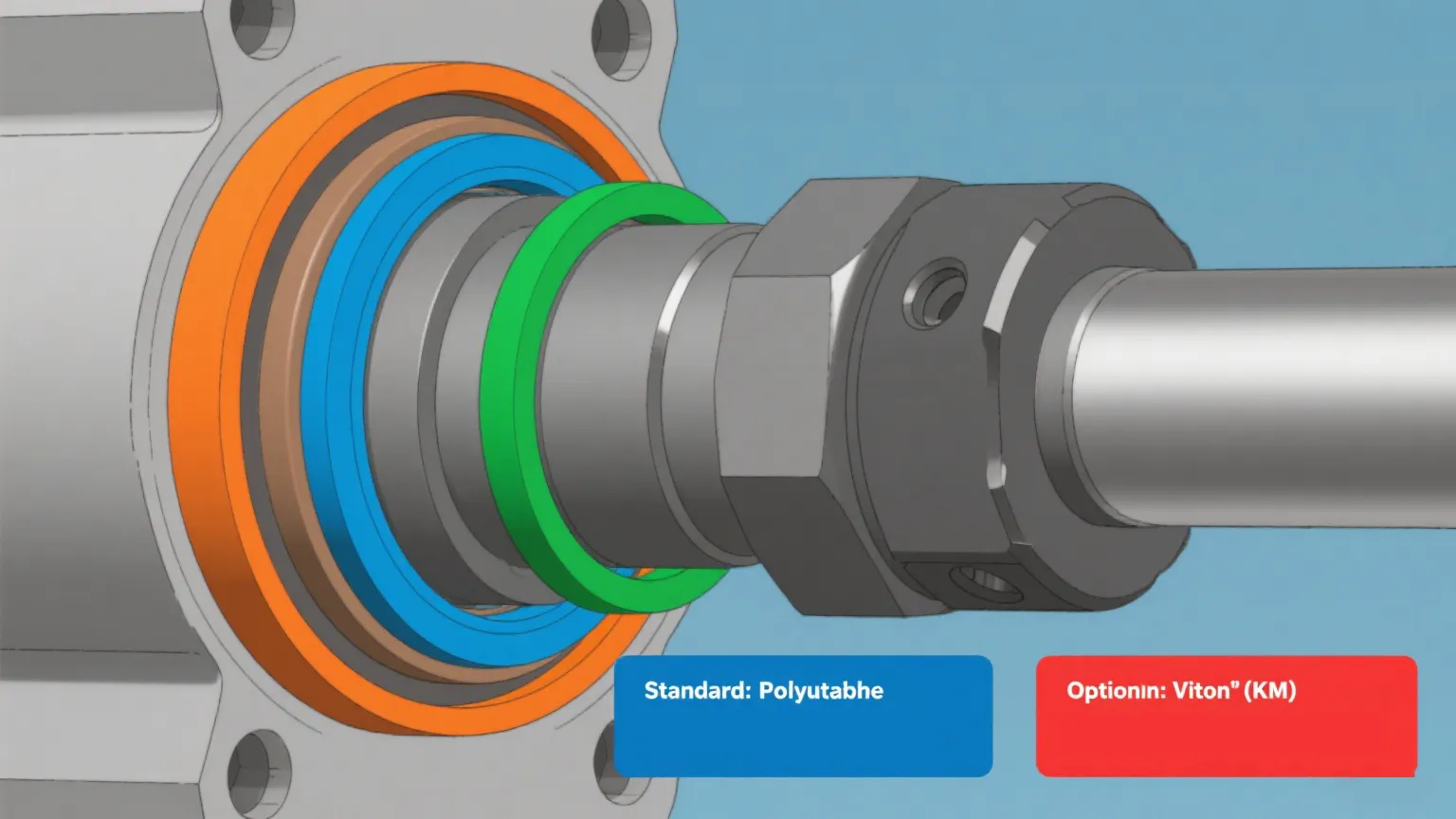

Step 3: Choose Your Seal Compound

The operating environment dictates the best seal material.

Step 4: Special Materials & Coatings

For corrosive environments or specific aesthetic requirements:

Hydraulic lift cylinders are the workhorses behind lifting, lowering, tilting, and stabilizing tasks across countless industries. These linear actuators take hydraulic energy and turn it into precise mechanical movement, making them indispensable for reliable force transmission in all kinds of setups. At Raydafon, we build our hydraulic lift cylinders to hold up in tough conditions—blending strength, precise control, and long service life to get the job done right, no matter the environment. Let’s break down where these cylinders shine most.

Take material handling and lifting platforms, for example. You’ll find our heavy-duty hydraulic lift cylinders hard at work in scissor lifts, lift tables, mobile loading docks, and aerial work platforms. They’re built to handle big loads while moving smoothly, which means safer, more controlled lifting of materials and people in warehouses and factories. Whether it’s a cylinder for a warehouse lift table, a scissor lift hydraulic actuator, or an aerial work platform hydraulic cylinder, these tools keep operations running without hitches, even with repeated use at different heights.

In agriculture, hydraulic lift cylinders are key players too. They power the vertical movement in all sorts of farm gear—seeders, grain dump carts, fertilizer spreaders, and bale handlers. Out in the field, dust, mud, and moisture are constant challenges, so our agricultural hydraulic lift cylinders come with tough seals and corrosion protection to keep performing. Think of a hydraulic cylinder for a grain cart, a lift actuator for a bale handler, or a farm dump bed lifting cylinder—these parts are made to stand up to the elements and keep the harvest moving.

Construction and earthmoving equipment rely on hydraulic lift cylinders just as much. From compact excavators to road rollers, these cylinders raise and stabilize arms, blades, hoppers, and buckets. They need to handle high pressure and rough treatment, which is why our lift cylinder for stabilizer legs, hydraulic actuator for concrete mixers, and rugged lift actuator for road rollers are built tough. No matter how bumpy the job site, these cylinders deliver the reliable lifting power needed to get construction work done on time.

Transport and utility vehicles depend on hydraulic lift cylinders for loading and unloading. Tailgate lifts, truck-mounted cranes, container hoists, and dump truck beds all use these cylinders to move smoothly, even in tight spaces or on uneven ground. A tailgate lift actuator for trucks, hydraulic hoist cylinder for trailers, or dump bed cylinder with tilting function from Raydafon fits compactly, offers two-way control, and doesn’t need constant maintenance—keeping delivery and utility work on track.

Logistics automation systems are another area where hydraulic lift cylinders make a big difference. Automated storage and retrieval systems (AS/RS), robotic palletizers, and conveyor line lifts all use these cylinders for precise vertical positioning. They need to be compact, quiet, and energy-efficient to keep up with high-demand operations. Our vertical positioning actuator in logistics, hydraulic lifter for AS/RS, and cylinder for conveyor lift system are designed to integrate seamlessly, moving smoothly and repeating precise motions day in and day out.

At Raydafon, we know every industry has unique needs—whether it’s a specific load capacity, extra-durable seals, or a custom installation design. That’s why our hydraulic lift cylinders are tailored to fit, from industrial platforms to automated logistics. Whether you’re looking for a Raydafon hydraulic cylinder for a warehouse lift, a lift cylinder for a farm machine, or a vertical motion control solution for construction gear, we make sure each product meets the demands of the job. After all, in agriculture, warehousing, construction, or transportation, these cylinders are the backbone of controlled, reliable lifting—and we’re here to keep that backbone strong.

x x |

/upload/8293/image/20250808/application-of-lift-hydraulic-cylinder--8--134720.webp" alt="" /> |

|

|

We’re all about building hydraulic solutions that don’t just sound good on paper but hold up when real machinery hits real challenges. Production stays steady, designs stay practical, and that’s how our products—especially those rugged hydraulic lift cylinders—keep going strong, even in the thick of tough jobs.

You’ll find our work across a range of key industries: farm equipment, construction machinery, forklifts, ships, and off-road vehicles. In these spaces, we’ve honed our craft to make all sorts, from precise steering hydraulic cylinders and double-acting models to heavy-duty hydraulic lift cylinder setups built for specific, grueling tasks. Need a telescopic hydraulic lift cylinder for a tight spot on a harvester? Or maybe a corrosion-resistant hydraulic lift cylinder for marine use? We’ve got the know-how to deliver.

Quality here isn’t just talk. We stick strictly to ISO 9001 and ISO/TS 16949 standards, so every OEM hydraulic cylinder and part that leaves our shop meets the industry’s toughest requirements. This careful approach gives clients peace of mind—knowing their machinery will keep performing, day in and day out, for longer.

A big part of what we do is rolling up our sleeves to create custom hydraulic lift cylinder solutions. Bore size, stroke length, mounting style, surface treatment—we tweak all the details to fit exactly what you need, no matter how unique your setup is. Our seasoned team doesn’t just handle OEM projects; we also provide top-notch replacement parts for hydraulic lift cylinders in the aftermarket, so clients worldwide can find the perfect fit for their equipment, whether it’s a vintage forklift or a brand-new construction rig.

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Tel

+86-574-87168065

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Copyright © Raydafon Technology Group Co.,Limited All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |