QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

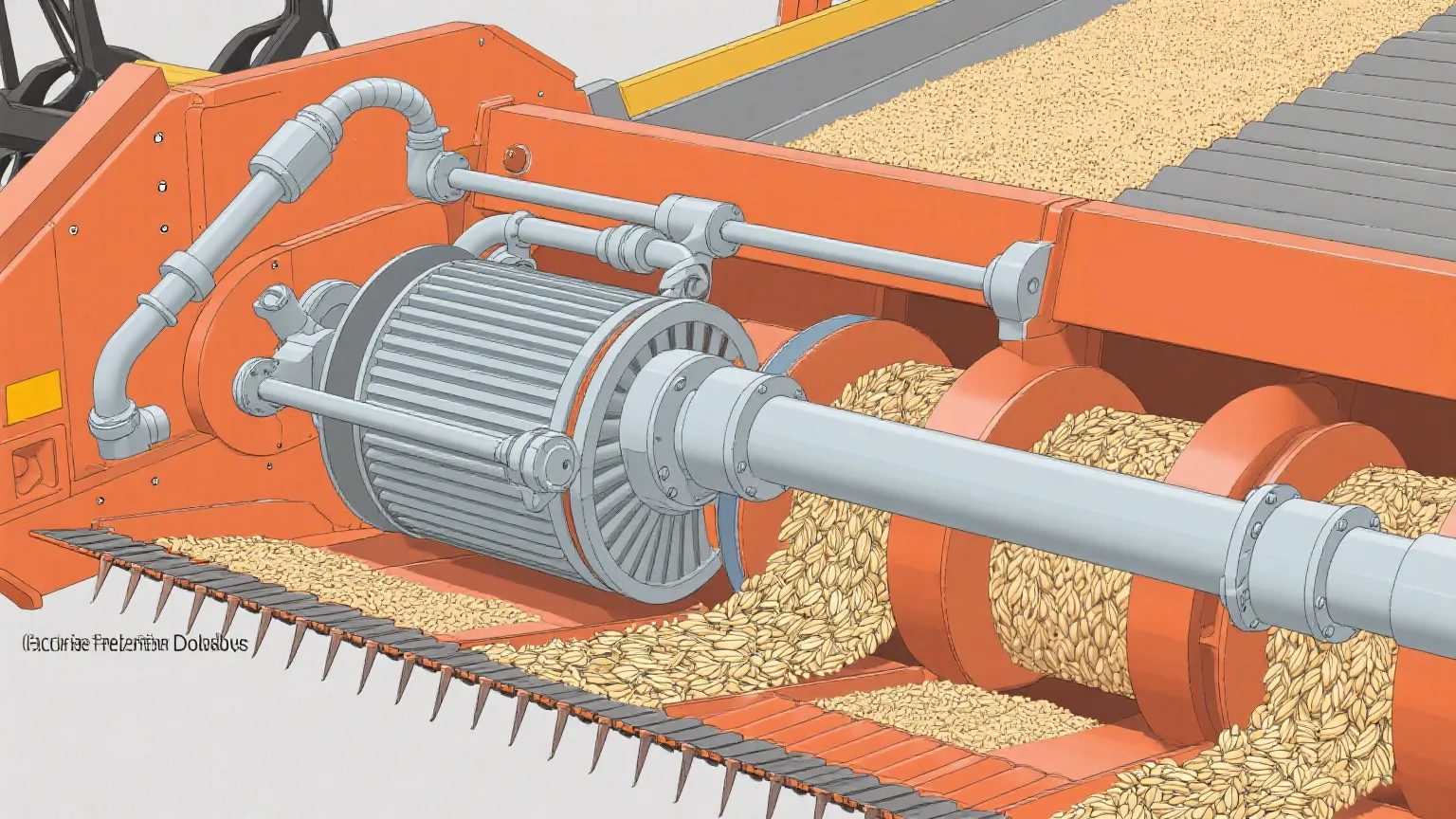

Harvesters work hard out in the fields, and they need parts that can keep up. That’s where Raydafon’s EP-HH-YG45*220-V90 Harvester Hydraulic Cylinder comes in—it’s built specifically for these tough machines, whether you’re running a combine or a sugarcane harvester.

Think about a combine chugging through a wheat field. It’s got to lift the cutting head up and down to match the ground, move the grain elevator smoothly, and dump the harvest cleanly when it’s time. This cylinder is the muscle behind all that. It pushes with just the right force, so the operator can make tiny adjustments without any jerking. No more missed cuts or spilled grain—just steady, reliable action, even when the field’s bumpy. That’s why folks who run combines swear by it as a solid combine harvester hydraulic cylinder.

Sugarcane fields are a whole different beast. The stalks are thick, the ground’s often muddy, and the machines are working nonstop under the sun. This cylinder doesn’t back down, though. Made from tough alloy steel, it takes the beating of lifting heavy cane and chopping through thick bunches day in and day out. The seals are extra strong too—they keep the hydraulic fluid in and the dirt, sap, and rain out. So even in those sticky, wet conditions, it keeps going. For sugarcane farmers, that makes it a go-to sugarcane harvester hydraulic cylinder.

What’s nice is that Raydafon doesn’t just slap parts together. Their factory in China follows strict rules—ISO 9001 standards—to make sure every cylinder is up to snuff. They test each one hard: how it handles pressure, how long it lasts under repeated use, even if it can take the heat or cold. It’s not just about checking boxes; it’s about making sure it holds up when you’re in the thick of harvest and can’t afford a breakdown.

And if your harvester is a bit unique? Maybe it’s an older model or has some custom tweaks? They get that. You can ask for custom harvester hydraulic cylinders—longer strokes, different mounting bits, whatever fits your machine. No need to make a standard part work; they’ll make it fit your setup.

This hydraulic cylinder is built to precise dimensions for seamless integration with your harvesting equipment. Please verify these specifications against your requirements or contact our technical support for assistance.

|

Specification |

Measurement |

Notes |

|

Model |

EP-HH-YG45*220-V90 |

Raydafon Harvester Series |

|

Cylinder Bore Diameter |

55mm |

Provides optimal force for its class. |

|

Rod Diameter |

40mm |

Hard-chrome plated for wear and corrosion resistance. |

|

Stroke Length |

220mm |

The effective range of motion. |

|

Installation Distance |

385mm |

Critical for correct mounting and geometry. |

When it comes to harvesting operations, the EP-HH-YG45*220-V90 isn’t just a run-of-the-mill component—it’s the kind of harvester hydraulic cylinder that keeps your operation on track when the clock is ticking and the fields are waiting. With bore, stroke, and mounting dimensions dialed in to fit countless combines and harvesters, it’s built to step up where it matters most, no matter the brand or model.

Take the header, for example—the frontline of your harvest. It needs to shift fast: lower for short crops, raise for tall ones, tilt to match a slope. That’s where this heavy-duty harvester hydraulic cylinder comes in. It doesn’t just lift or tilt—it does it with the kind of control that keeps the cutterbar dead-on, so you won’t see uneven stubble or rows left uncut, even when the ground gets bumpy.

Then there’s the reel. Get its position wrong, and you’re either missing crops or crushing them. This precision harvester hydraulic cylinder lets you nudge the reel up, slide it forward, or slow its spin—whatever the crop needs. Suddenly, plants feed into the machine like they’re supposed to, no gaps, no waste, just a steady flow that keeps the harvest rolling.

Unloading grain? Spills and delays eat into your day. This reliable harvester hydraulic cylinder powers the auger’s swing, letting it pivot smooth as silk to line up with the cart or trailer. Whether you’re filling a small wagon or a big rig, every bushel lands where it should—no mess, no lost time, just efficient work.

Inside the harvester, the threshing system thrives on small tweaks. In some models, this harvester hydraulic cylinder adjusts concave clearance or fine-tunes parts to make sure even tough crops get stripped clean, without bruising the grain. It’s not flashy, but those tiny adjustments add up to bigger yields when it counts.

And let’s not forget steering. Maneuvering a big self-propelled harvester through tight spots or around rocks takes muscle, but this robust steering assist harvester hydraulic cylinder eases the load. Turns go from heavy and jerky to smooth and steady, even on uneven ground, so operators stay sharp from dawn to dusk.

Whether you’re running a John Deere, Case IH, or another brand, this harvester hydraulic cylinder doesn’t just replace the original—it often outlasts it. Not sure if it fits? Tell our team your machine’s make and model, and we’ll get you sorted. Because in harvesting, the right part isn’t just a convenience—it’s a game-changer.

|

|

|

|

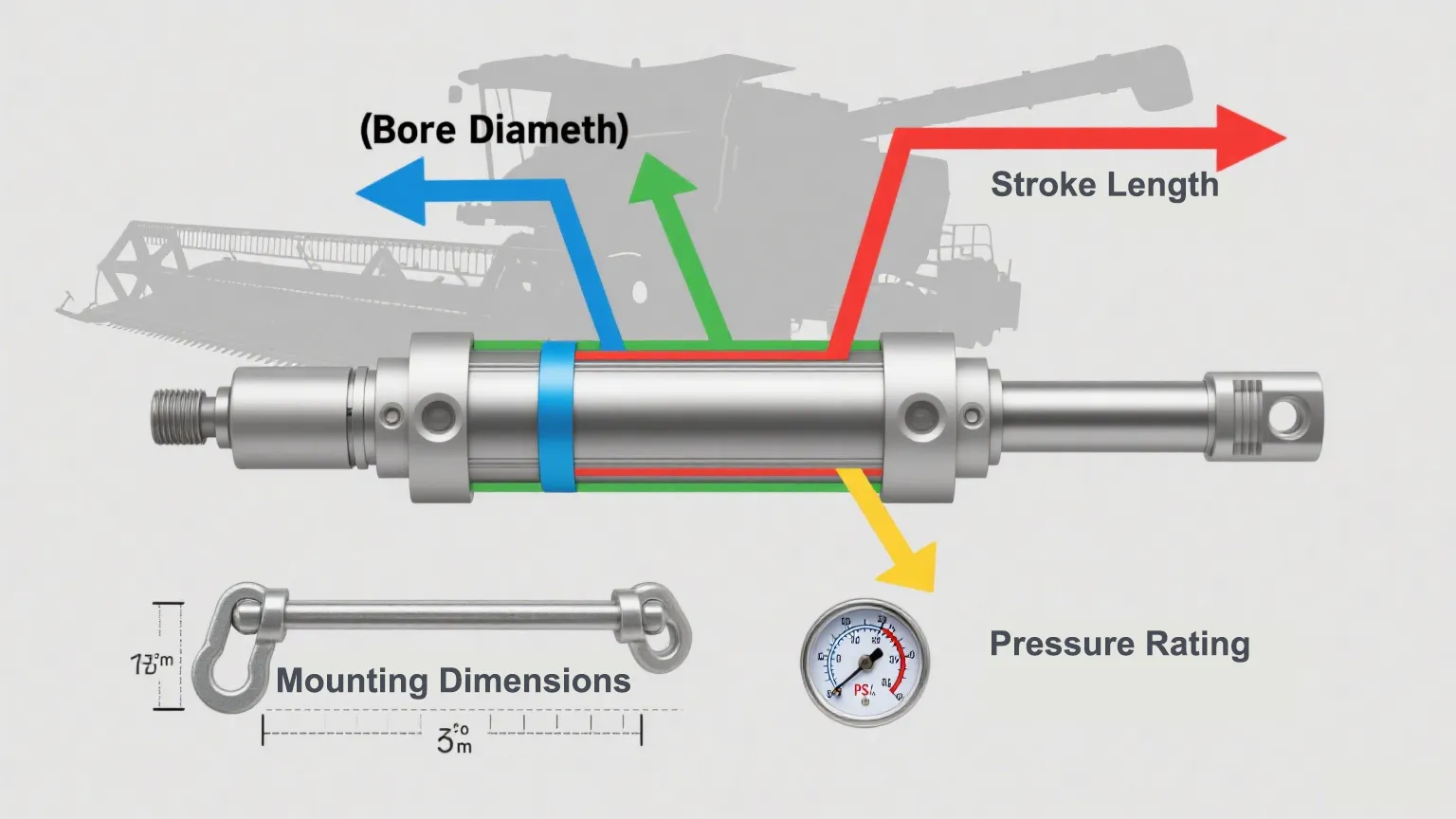

Picking the right harvester hydraulic cylinder isn’t just about grabbing any part off the shelf—it’s about making sure it fits your machine like a glove, keeps you safe, and gets the job done when the fields are calling. Let’s start with the basics that matter most.

First up, bore diameter. This is what determines how much muscle your harvester hydraulic cylinder has. Too small, and it’ll struggle to lift that heavy header when you’re in thick crops. Too big, and you’re wasting power that could go elsewhere. Check your old cylinder’s specs or your harvester’s manual—this number needs to match, plain and simple, if you want the kind of force that handles tough days in the field.

Then there’s stroke length. That’s how far the rod can stretch out or pull back. If it’s too short, your header might not lift high enough to clear rocks or uneven ground. Too long, and it could hit other parts of the machine when retracted. Measure the old harvester hydraulic cylinder’s stroke—from fully retracted to fully extended—and make sure the new one matches. It’s a small detail, but it’ll save you from headaches like jammed parts or limited movement.

Mounting dimensions are another big one. This isn’t just about bolts lining up—it’s about the retracted length from pin to pin and the type of mounts, like clevis or pin-eye. If these don’t match, your harvester hydraulic cylinder might sit at a weird angle, causing extra wear on seals or even bending the rod over time. Grab a tape measure, check where the mounts attach, and make sure the new cylinder’s dimensions mirror the original. It’s how you keep things running smooth, no extra stress on the machine.

Pressure rating is non-negotiable. Your harvester’s hydraulic system runs at a specific pressure, and your harvester hydraulic cylinder needs to handle that—no exceptions. Slap in one with a lower rating, and you’re looking at leaks, blown seals, or worse, a cylinder that fails when you’re in the middle of harvest. Stick to the original specs unless you’ve got a pro engineering a modification—even then, proceed with caution.

At the end of the day, the right harvester hydraulic cylinder is the one that checks all these boxes. It’s not about fancy features—it’s about fit, strength, and matching what your machine was built to handle. Get that right, and you’ll keep your harvester running strong, from dawn till dusk.

(Note: These are representative testimonials reflecting typical customer feedback for the US market.)

Our combine’s header lift had turned into a hassle—slow, jerky, like it was fighting every move. We swapped out the old ones for these Raydafon heavy-duty harvester hydraulic cylinders right before last fall’s corn harvest, and man, what a change. Smooth as butter, responsive when you need it, and they didn’t flinch through 1,200 acres of rough ground and thick stalks. This durable harvester hydraulic cylinder is worth every penny—solid performance, fair price, can’t ask for more. - Farm Manager, Iowa

I’ll admit, I was wary of going non-OEM. But the price difference on that EP-HH-YG45*220-V90 high-performance harvester hydraulic cylinder was too big to ignore. Turned out, it slid right into our older harvester like it was made for it. Install? A breeze. And it’s been chugging along flawlessly ever since. Build quality? Feels just as tough as the original—heavy, solid, no cheap corners. This reliable harvester hydraulic cylinder is a game-changer for small operations like mine. - Independent Farmer, Nebraska

We run a crew of custom harvesters, so our machines breathe dust day in and day out. Tried other replacement harvester hydraulic cylinders before—seals would give out by season’s end, every time. These Raydafon long-lasting harvester hydraulic cylinders? Two seasons deep, not a single leak. The rod’s chrome? Top-shelf stuff, no scratches or scoring, even with all the grit flying around. That’s the kind of durability you need when you’re racing the weather. - Custom Harvester Owner, Kansas

Mid-harvest, our auger swing harvester hydraulic cylinder gave out—total nightmare. Called Raydafon’s support, and they walked me through finding the right direct-fit harvester hydraulic cylinder, confirmed the specs, and shipped it same day. That quick help? Saved us from losing a full day in the field. Having a trustworthy harvester hydraulic cylinder supplier that backs their parts? That’s why we’ll be back. - Co-op Operations Manager, Illinois

It’s not about how much you pay upfront—it’s about how much you don’t pay in repairs later. These rugged harvester hydraulic cylinders? Rock solid. We’re spending less time under the machine fixing leaks or replacing parts, more time actually harvesting. For any farmer, that’s the bottom line. Raydafon’s got our business from here on out, especially for their high-quality harvester hydraulic cylinders. - Family Farm Owner, Ohio

Raydafon builds hydraulic cylinders—no frills, just solid gear—right in Zhejiang Province’s busy industrial belt.

We’ve been at this over a decade now. Started out making all kinds—for harvesters, construction machines, you name it. But over time, we realized where we shine: building hydraulic setups specifically for farm tractors. Focusing like that? It’s made us better. Our shop runs smoother, our team knows the ins and outs of tractor hydraulics, and every cylinder gets put through the wringer to make sure it holds up when the going gets tough.

Walk through our factory, and you’ll see what I mean. The machining area has tools that carve metal with pinpoint accuracy. The assembly line? Guys there have been putting cylinders together so long, they can spot a loose seal from a mile away. And the coating room? They lay down finishes that laugh off rust, even in muddy fields. It’s a team effort—managers who’ve been here since day one, designers who’ve got dirt under their nails from working on tractors, and technicians who take it personal if a cylinder isn’t perfect.

We don’t mess around with big slogans. But if we had to sum it up? We use good tech to make better parts, we stand behind what we build, we take pride in doing the job right, and we stick around to help our customers succeed. That’s Raydafon.

|

|

|

|

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Tel

+86-574-87168065

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Copyright © Raydafon Technology Group Co.,Limited All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |