QR Code

Products

Contact Us

Fax

+86-574-87168065

E-mail

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

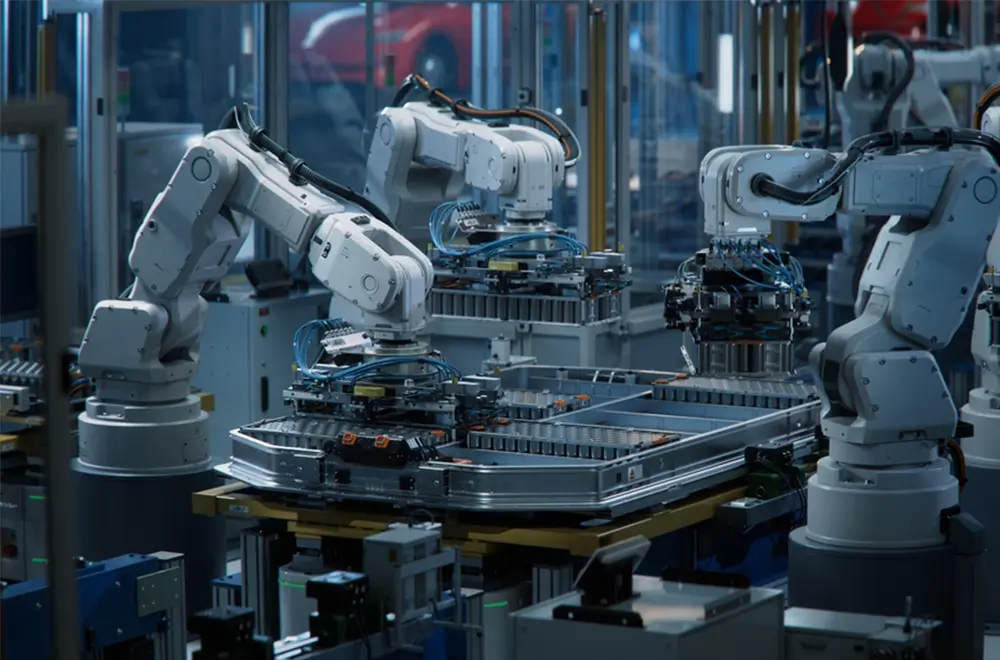

As the manufacturing industry continues to move towards intelligence and flexibility, industrial automation systems have become a key component to improve production efficiency, reduce labor costs and ensure product quality. Raydafon provides a variety of hydraulic and mechanical transmission solutions around the power execution and precision transmission needs of automation equipment, and widely serves many fields such as automated assembly lines, intelligent robots, logistics sorting systems, CNC equipment, food packaging equipment, and testing devices.

In the actual application of smart factories, Raydafon's hydraulic cylinders are often used in the lifting platforms, pushing devices, clamping systems, and material displacement mechanisms of equipment. They have the characteristics of fast response speed, stable thrust, and compact structure, and can maintain high consistency in changing action rhythms. For equipment that frequently moves in automatic sorting, assembly, or handling processes, the stable performance of hydraulic cylinders is directly related to production rhythm and precision control.

In terms of power output and rotation control, Raydafon's planetary reducers and precision gears are often integrated into servo systems, stepper motors, and robot drive units to achieve precise positioning, low-noise operation, and high-efficiency transmission. Its high torque density and low backlash characteristics are suitable for equipment with strict requirements for repeated positioning accuracy, synchronous operation, and micro-gap control, such as multi-axis robotic arms, laser cutting machines, high-speed assembly units, etc. At the same time, in applications where space is limited but load requirements are high, Raydafon's compact transmission design also greatly improves the flexibility of equipment integration.

During the continuous operation of the production line, the long-term stability of the equipment is particularly critical. All Raydafon products are designed based on industrial site conditions, with good wear resistance, load-bearing capacity and structural strength, supporting continuous operation under high frequency and high load, and widely adapting to the needs of industries such as 24-hour non-stop electronic manufacturing, automotive parts processing, and pharmaceutical packaging.

In addition, we also support non-standard customization to help customers provide matching hydraulic actuators and transmission mechanisms based on actual needs such as automation system layout, load parameters, and control methods. Whether it is the automation transformation of a single station or the integrated development of the entire intelligent production line, Raydafon can provide highly reliable, easy-to-integrate, and easy-to-maintain product support and technical guarantees.

+86-574-87168065

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Copyright © Raydafon Technology Group Co.,Limited All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |